- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

155 kW

-

Weight (KG):

-

255600 KG

-

Application:

-

Rubbers Recycling Industry

-

Machine Type:

-

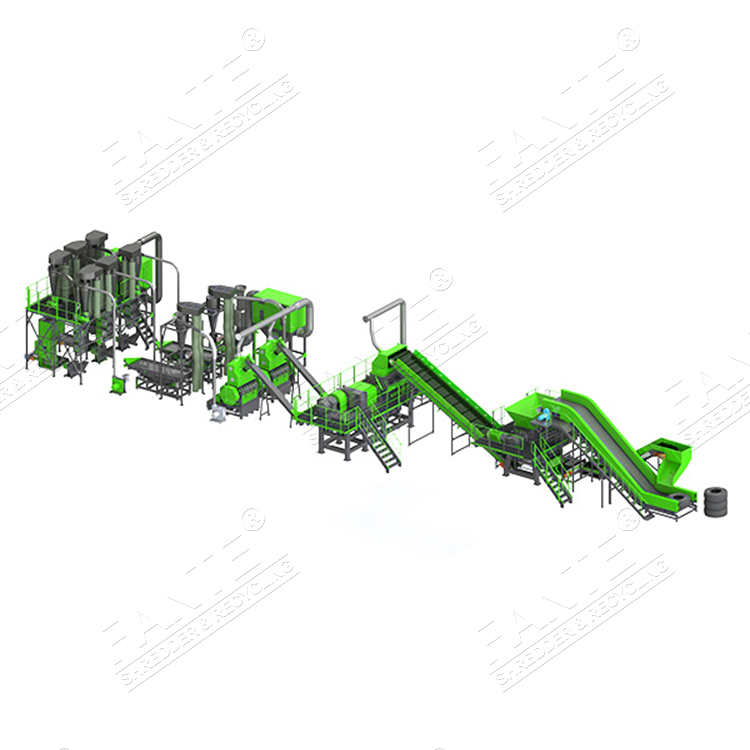

Fully Automatically Tire Recycling Machine

-

Usage:

-

Used Tire Recyling

-

Final product:

-

10-200mesh Rubber Powder

-

Tyre type:

-

Bus Tyre

-

Color:

-

Customer Request

-

Advantage:

-

Higher Efficiency

-

Marketing Type:

-

New Product 2022

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fante

-

Voltage:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

155 kW

-

Weight (KG):

-

255600 KG

-

Application:

-

Rubbers Recycling Industry

-

Machine Type:

-

Fully Automatically Tire Recycling Machine

-

Usage:

-

Used Tire Recyling

-

Final product:

-

10-200mesh Rubber Powder

-

Tyre type:

-

Bus Tyre

-

Color:

-

Customer Request

-

Advantage:

-

Higher Efficiency

-

Marketing Type:

-

New Product 2022

◼︎

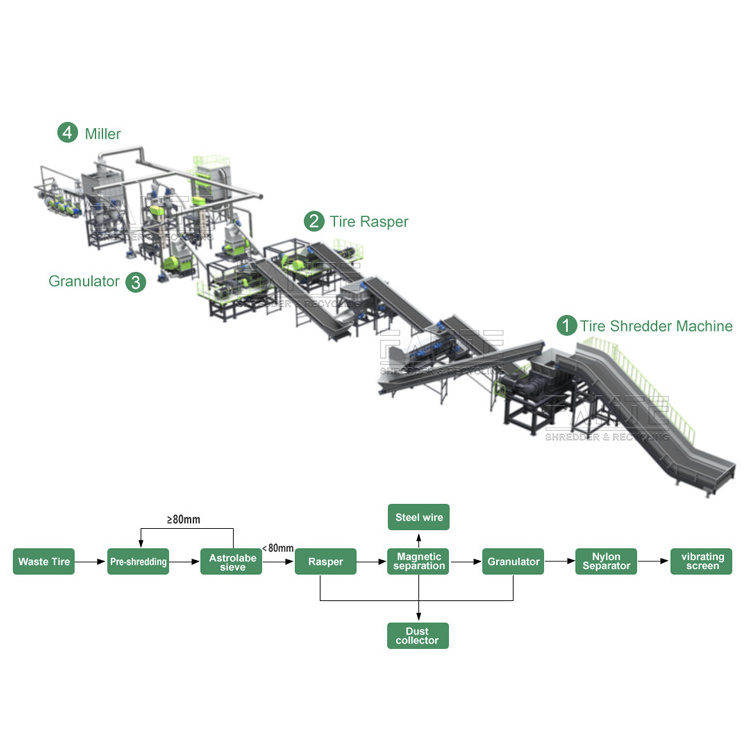

Waste tire recycling rubber powder machine is suitable for fifferent kinds if the scrap tires,and we can procide you the best solution based on your differnet tires.

|

Model

|

FTHS-1000

|

FTHS-1200

|

FTHS-1600

|

FTHS-1800

|

|||

|

Motor

|

(22-37)KW*2

|

(22-45)KW*2

|

(45-110)KW*2

|

(55-132)KW*2

|

|||

|

Cutting ChamberL*W

|

1000*680

|

1204*920

|

1604*1360

|

1804*1410

|

|||

|

Blade Diameter

|

450mm

|

450mm

|

560mm

|

750mm

|

|||

|

DimensionsL*W*H

|

3800*1400*2100

|

5010*1710*3100

|

5260*2420*3890

|

5870*2450*3890

|

|||

|

Equipment Weight

|

6000kg

|

15500kg

|

22000kg

|

25000kg

|

|||

|

Final Product

|

50-150mm

|

|

|

|

|||

FTHS tire shredder is controlled by PLC unit enabling automatic reverse for overload protection and minimizing blades damages

Our knife design operates at extremely close tolerances which produces the clean cut with very little exposed wire, and with over 13 processing steps ensure the best performance and precision tolerance. The tire shredder knives can be resharpened and reused which significantly increases lifespan and decreases costs.

|

Model

|

FTRR-315

|

FTRR-135

|

FTRR-90

|

FTRR-75

|

|||

|

Power

|

315kw

|

135kw

|

90kw

|

75kw

|

|||

|

Voltage

|

as per request

|

|

|

|

|||

|

Cutting chamber

|

700*1500mm

|

640*1200mm

|

550*1000mm

|

550*800mm

|

|||

|

Dimension

|

6220*2170*3560mm

|

4110*2010*2560mm

|

4100*2090*2180mm

|

4100*1990*1980mm

|

|||

|

Weight

|

Approx 24000kg

|

Approx 13500kg

|

Approx 9200kg

|

Approx 8500kg

|

|||

|

Hopper Opening

|

1730*880*910mm

|

1410*910*1410mm

|

1190*710*1250mm

|

980*700*1260mm

|

|||

|

Final Product

|

10-30mm

|

|

|

|

|||

FTRR series Rasper is specially designed to take pre-shredded tires chips and produce between 20-10mm wire free rubber chips, it is secondary tire recycling machine in whole tyre recycling process.

FTRR rasper is used as secondary tire recycling machine for primary size reduction of pre-shredded chips, it allows it to separate the wire from rubber tires in the purest, cleanest form possible, allowing processors to generate revenue streams from both rubber and wire..

Main features:

◼︎

The rotor is manufactured and designed for minimum wear;

◼︎

Easily exchangeable blades and screens enable the possibility to maintain the machine efficiently;

◼︎

Screens with different hole sizes available for flexible production;

◼︎

The internal wear surfaces are lined with replaceable wear liners that are easily changed when worn. This exclusive feature of rasper eliminates the need for any maintenance welding and results in greater machine uptime.

|

Model

|

FTC-H-1600

|

FTC-H-1200

|

FTC-H-1000

|

FTC-H-800

|

|||

|

Motor

|

135kw

|

90kw

|

45kw

|

37kw

|

|||

|

Cutting Chamber W*L

|

1080*1600mm

|

745*1200mm

|

580*1000

|

580*800

|

|||

|

Dimensions L*W*H

|

2350×2810×4330

|

2150*2250*2950

|

1770*1900*2450

|

1770*1660*2400

|

|||

|

Weight

|

9700Kg

|

7600Kg

|

4300Kg

|

3650Kg

|

|||

|

Final Product

|

1-6mm

|

|

|

|

|||

FTC-H series rubber granulator is specialized designed for tyre shredding process, the end product after our granulation process will be 99.9% fiber free rubber crumb..

Main features:

FTC-H series Rubber Granulator is the third step in the who tire recycling step. At this step, wire free mulch (10-20mm rubber ) is processed from rasper into the granulator, which grinds further into 1-5mm granules. The granules are rescreened and re-circulated until the desired size is reached. During the crumb rubber granulation process, 99.9% of the fiber is removed.

The Fine Granulator has an adjustable knife clearance optimizing the cutting function. The knives are not only easy to access and change, but can also be reground on a “flat-bed” grinder. Exchangeable wear parts give you a tough machine. Screens with different hole sizes available to ensure a more flexible production..

|

Model

|

FT-XMF-330

|

FT-XMF-420

|

|

|

Grinding Disc DIA

|

270mm

|

380mm

|

|

|

Output Size

|

30-60mesh

|

|

|

|

Shaft Speed

|

460Rpm

|

520Rpm

|

|

|

Motor Power

|

22kw

|

30kw

|

|

|

Fan Motor Power

|

7.5kw

|

7.5kw

|

|

|

Weight

|

2500kg

|

3200kg

|

|

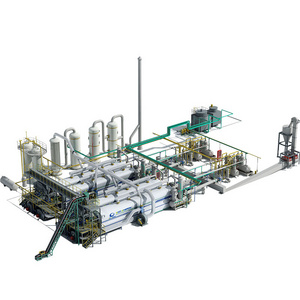

This tyre recycling equipment composes of one rubber pulverizer, cyclone collection structure and whole electrical system. The main recycling machine, rubber pulverizer include main motor, infinitely variable transmission motor, feeding and adjustable parts, as well as one pair stationary and rotary grinding discs. The basic principle of the scrap tyre recycling machine is the two discs rotate in different orient creates friction between them, this friction generates forces to cut and grind the materials until desired size reached. It adopts wind and water cooling system to control the grinding temperature, makes sure the high quality of the grinded material, so as to meet the products requirement.

This structure of tyre recycling equipment is compact with low noise, high output, low energy consume, which is easy to disassemble and assemble. According to all the advantages it has, the miller is easy to operate and the output fine powder is extremely uniform.

Hot Searches