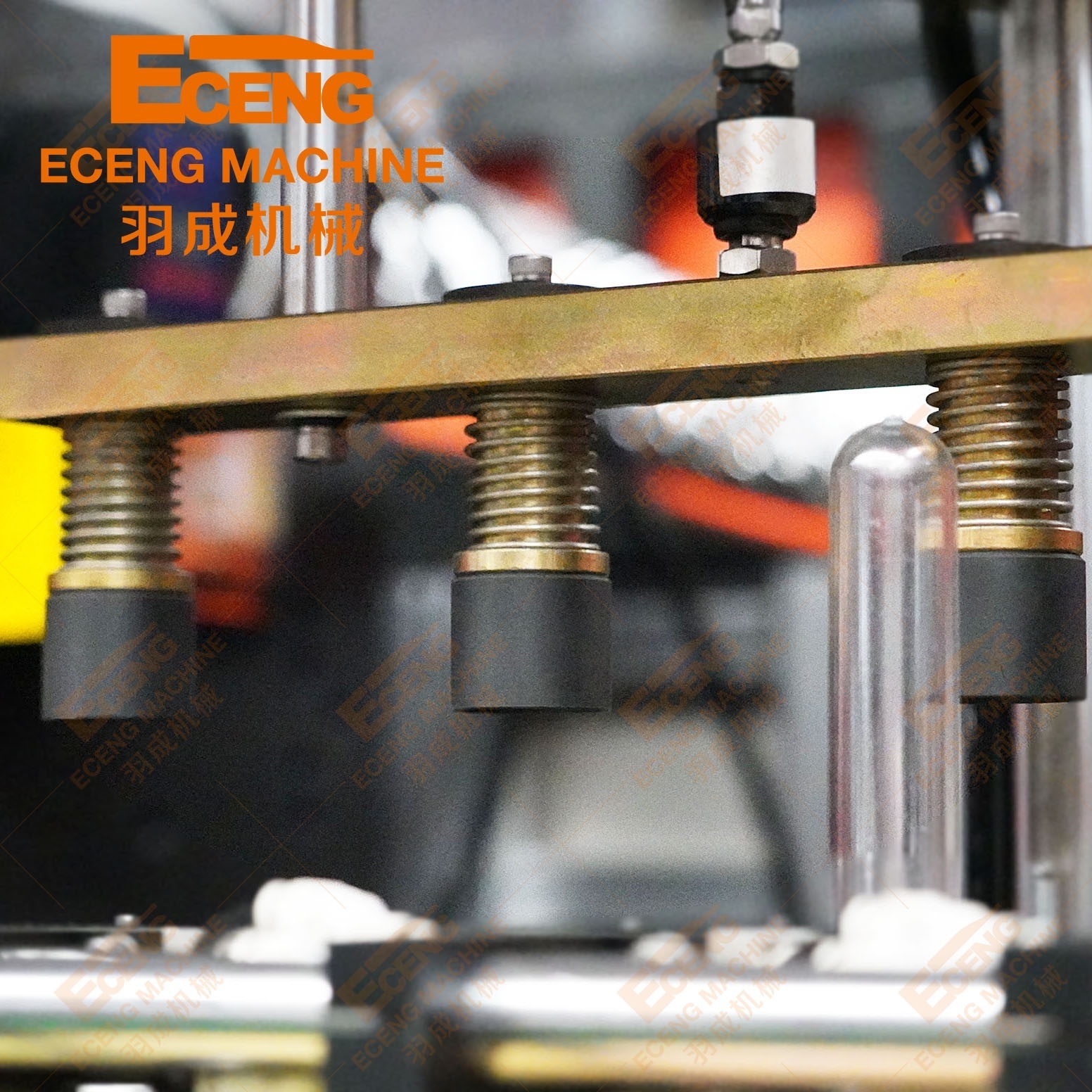

We always recommend our clients to hold a set of spares in stock, for every kind of machinery they buy from us. This will help in smooth functioning of your manufacturing facility, without any obstacles.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Eceng

-

Year:

-

2023

-

Voltage:

-

380V,50HZ

-

Dimension(L*W*H):

-

4.1*2.16*2.45(m)

-

Hollow part volume:

-

2L

-

Power (kW):

-

82.5

-

Weight (KG):

-

4300 KG

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Automatic:

-

Yes

-

Model Number:

-

Q6000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

warranty:

-

1 year

-

Certification:

-

CE

-

Product name:

-

Automatic Blowing Molding Machine

-

Bottle material:

-

PET Material

-

Production Capacity (BPH):

-

6000 BPH

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Eceng

-

Year:

-

2023

-

Voltage:

-

380V,50HZ

-

Dimension(L*W*H):

-

4.1*2.16*2.45(m)

-

Hollow part volume:

-

2L

-

Power (kW):

-

82.5

-

Weight (KG):

-

4300 KG

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Automatic:

-

Yes

-

Model Number:

-

Q6000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

warranty:

-

1 year

-

Certification:

-

CE

-

Product name:

-

Automatic Blowing Molding Machine

-

Bottle material:

-

PET Material

-

Production Capacity (BPH):

-

6000 BPH

|

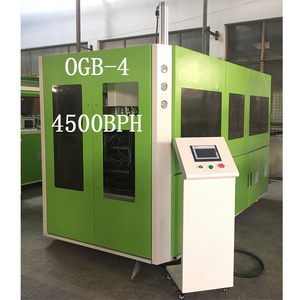

Model Q6000

|

|

|

||

|

Bottle type specification

|

Cavity

|

4

|

||

|

|

Max.volume

|

2L

|

||

|

|

Bottle mouth maximum overall diameter

|

28-38mm

|

||

|

|

Bottle biggest diameter

|

105mm

|

||

|

|

Bottle maximum height

|

330mm

|

||

|

Capacity specification

|

Theory output

|

6000BPH

|

||

|

|

Bottle type volume

|

500ML

|

||

|

|

Bottle type weight

|

17g

|

||

|

|

Bottle type

|

Circular

|

||

|

Power specification

|

Light tube quantity

|

40pcs

|

||

|

|

Light tube power

|

2KW/2.5KW

|

||

|

|

Maximum heating power

|

82.5KW

|

||

|

|

All electric machine installation

|

91KW

|

||

|

|

Actual consumption

|

40%-70%

|

||

|

Air pressure specification

|

Work pressure

|

7-9kg/cm2

|

||

|

|

Blow bottle pressure

|

25-35kg/cm2

|

||

|

|

Higher -pressure air consumption

|

3000Ltr/min

|

||

|

Frozen water specification

|

Work pressure

|

5-6 kg/cm2

|

||

|

|

Temperature range

|

10℃

|

||

|

|

Consumption

|

8000kcal/hr

|

||

|

|

Frozen water flow

|

138L/min

|

||

|

Machine specification

|

Machine size

|

4.1x2.16x2.45

|

||

|

|

Machine weight

|

4.3ton

|

||

Eceng

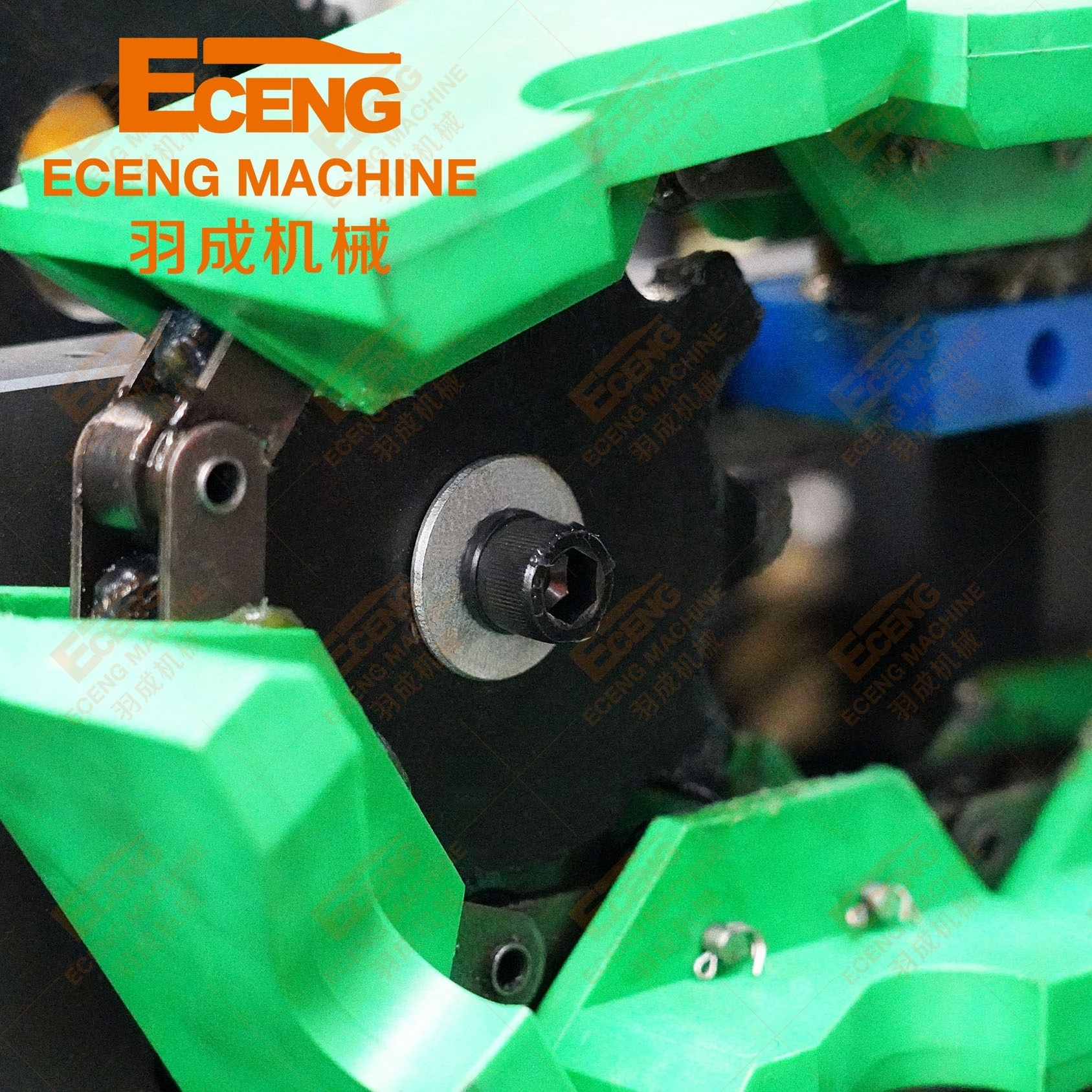

Q series is a stable two-step blow-down stretch automatic blowing machine.It can be used from 2 cavity to 9 cavity with a speed of 1000 bottles per hour (500 ml plastic bottles),max volume 2L plastic bottle,suitable for blowing any kind of carbonated beverage bottle,sparkling beverage bottle,pure water bottle, mineral water bottle,fruit juice beverage bottle,cosmetic bottles,large diameter bottles, high temperature resistance bottles and other packaging bottles.

Q linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

Q series linear bottle blowing machine features:

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control, simple operation.

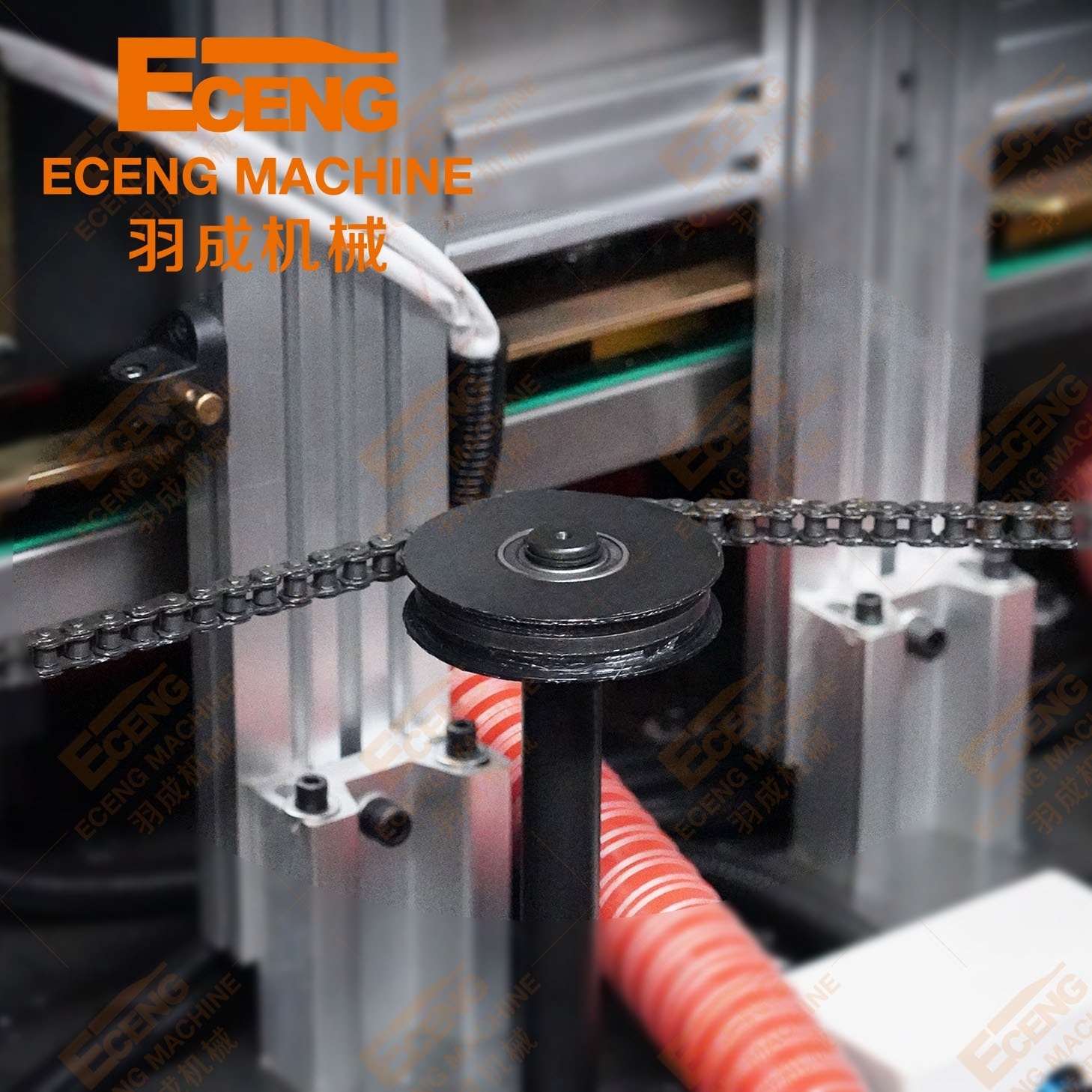

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle .

Spares Services

1.Air Compressor :

Compress air,used for blowing bottle and blower action.

2. Air Dryer And F

ilter

:

Cooling and dry air,improve bottle quality,prolong phnuematic parts life.

3. Chiller :

Cooling mould,make the machine suitable to working 24 hour per day.

Eceng Machinery a professional bottle blowing machine factory in China, was established in 2007,provide a complete production system from preform production, bottle blowing, filling, to final packaging.With 17 years of industry experience, we have become a leading player in the field.

We understand that the biggest troubles for customers when purchasing and using bottle blowing machines are the difficulties in operation and maintenance. That's why we created Eceng Bottle Blowing Machine, which incorporates Western European technology to offer highly automated and user-friendly bottle blowing equipment.

we offer a one-year product warranty and lifetime technical support and special emphasis on remote training videos, an innovative service that allows our engineers to analyze and resolve machine alarms or other problems through video connections. This way, even customers who are not familiar with the operation can easily handle the bottle blowing machines.

we believe in a "one transaction, lifelong service" philosophy. Our goal is to comprehensively address our customers' concerns, allowing them to focus on efficient production.

1.Design machine according your requirements

We offer customized bottle shape/ logo/ color design based on customer requirements.

2.Arrange engineer to customer's factory

We will send our professional engineers to your factory to install the machines and train your staff how to operate the machines.

3.video training

The content of training is structure and maintenance of equipment, control and operation of equipment.

12 Months guarantee and life-long technical support

Engineers is available 24/7 online, always ready to assist customers with any operational issues they may encounter.

Normally the inner package, we will packed by the stretch film. Outer package we will use the export woodencase. Mostly we deliver the goods by sea as the freight is most reasonable in this way.

FAQ

Q:Your company is a trading company or a direct factory?

A:We are a direct factory which locates in Zhangjiagang city. in close proximity to Shanghai and Wuxi. If you arrive at either Shanghai or Wuxi, we can arrange transportation to pick you up and accompany you for a visit to our factory.

Q: How can I know your machine works well?

A: Before delivery, we will debug the production line, take photos, videos and send them to you via mail or instant tools.And you are welcome to come to visit our factory,and see the machine running.

Q:All of your products are made by yourself or compacted via purchasing the others?

A:We have independent technical team who focus on making machines,all the products are made by our technical team.

Q:What is the ability of your factory?

A:About 200 sets per year,customized requirements from 1 to 12 cavities, with production capacities ranging from a few hundred bottles to 36,000 bottles per hour.

Hot Searches