- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3100*1100*2850

-

Warranty:

-

free in one year

-

product name:

-

mini wood sawdust pelletizing machine

-

output:

-

1-1.5 t/h

-

forced feeder power:

-

0.55

-

conditioner power:

-

5.5

-

feeder power:

-

0.75

-

Ring die inner diameter:

-

420

-

granular size:

-

6-12

-

structure:

-

compact

-

Weight:

-

2900kg

-

Power(W):

-

55*2kw

-

Certification:

-

CE,ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Richi

-

Voltage:

-

380 can be customized

-

Dimension(L*W*H):

-

3100*1100*2850

-

Warranty:

-

free in one year

-

product name:

-

mini wood sawdust pelletizing machine

-

output:

-

1-1.5 t/h

-

forced feeder power:

-

0.55

-

conditioner power:

-

5.5

-

feeder power:

-

0.75

-

Ring die inner diameter:

-

420

-

granular size:

-

6-12

-

structure:

-

compact

-

Weight:

-

2900kg

-

Power(W):

-

55*2kw

-

Certification:

-

CE,ISO

CE Certificate Ring Die Biomass Sawdust Pelletizing Machine For Wood

| Factory Supply ring die granulator machine, wood pellet machine | |

|---|---|

|

Model: 250, 320, 350 Remarks: 1) the Model number means the diameter of the ring die of the feed pellet machine 2) the diameter of the final product pellet is Φ6-10 mm . |

|

Model: 420 Capacity : 1-1.5t/h Power : 90 Kw Weight : 2500kg Dimension : 2420*2200*2400 mm |

|

|

Model: 320 Capacity : 0.3-0.5 t/h Power : 37 Kw Weight : 2500 Dimension : 2200*1000*1500 mm |

|

|

Model: 350 Capacity : 0.5-0.8 t/h Power : 55 Kw Weight (kg):3500 Kg Dimension : 2500*1100*1600 mm |

|

|

♦ For bigger model of wood pellet machine, please click here. ♦ For wood pellet making production line, please click here. |

|

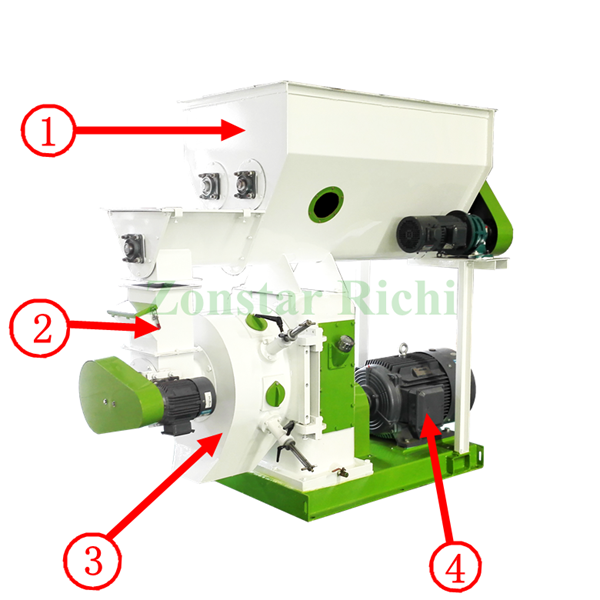

| The function of each part of Factory Supply ring die granulator machine, wood pellet machine | |

|---|---|

|

1) Feeder : feeding raw material into the pellet making chamber. the feeder is made of stainless steel.

2) Forced feeding unit: since the raw material is fluffy, and the bulking value is higher, we equip the force feeding device.

3) Pellet making unit: ring die and press roller inside work together to make the biomass wood raw material into wood pellet.

4) Main motor: driving the pellet making system.

We adopt the super quality Siemens brand motor in our machine. |

|

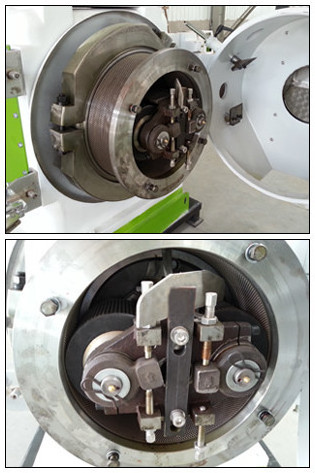

| Pelleting process working principle | |

|---|---|

|

|

|

♦ The main motor drive the ring die mould rotated. the press roller that were placed inside of the roller does not revolution, but will rotate because the friction of the ring die mould and wood powder raw material. ♦ The wood sawdust powder raw material was spread evenly into the space between the ring die and roller, and was press into the mould hole, formed column shape pellet, the pellet will rotate along with the rotating ring die mould and will be cutted when the length of the column pellet reach to a certain value. |

|

♦ The raw material could be branches, wood chipper, coconut sheel, nut sheel, rice or wheet straw, bean stem, wood sawdust, etc.

♦ If we use the raw material hay, forage grass, alfalfa, alfalfa, moringa oleifera, etc. we will get the final product silage fodder.

♦ We could produce wood pellet with different diameter by using different size of ring die mould. the range could be ø 6mm-10mm.

♦ The length of the wood pellet could be adjusted. there is a regulating device on the wood pellet machine.

1) How did you define your wood pellet machine model as 250 / 320 / 350 /420 / 508, etc. ?

The model is defined based on the diameter of the ring die mould.

For example, mould 250 means that the diameter of the ring die is 250 mm.

2) what kind of raw material that the ring die mould is made of?

There are two kinds of ring die mould in the market. one is made of carbon steel, the other is made of stainless steel. the former is cheaper than the latter.

We adopt stainless steel ring die and press roller sheel in our machine.

3) what about the size of the final wood pellet product?

the size is adjustable accroding to your requirement.

the diameter range of the wood pellet is ø6-10 mm by using different ring die mould.

the length of the wood pellet could be adjusted on the machine.

5) What is the suitable moisture (water content) of the raw material that easy to make pellet?

the ideal moisture range is from 15% to 18% .

6) What brand of motors you used in the machine?

We use Siemens brand motor in our machine. please rest assured about the quality.

7 ) what about the power, capacity, size and weight of the wood pellet machine?

Please refer to the above technical parameter table to get the detail.

If you want the details of bigger size of wood pellet making machine, please click here .

8) will you dispatch engineer to install the wood pellet machine (production line)?

Yes. we will dispatch engineer to do the service just based on the requirement of customers.

9) where is your factory located? how could I get there?

Our factory is located in Zhengzhou, Henan, China. It's 30 km far from the airport. we will pick you up at the airport.

10) what is your wood pellet machine price?

Please leave us a message at the bottom, and tell your detail requirement, will will reply you at first time.

Definitely, we could offer you the best machine with best price.

1) What's your raw material?

2) What about the maximum size and major size of the raw material?

3) What about your expecting size of the final product wood pellet?

3) what about the capacity? (how many ton per hour or day or year?)

4) are you the final user or you will sell the machine to others?

| You may need: flat die straw pellet press, pellet wood press machine | |

|---|---|

|

Capacity : 90-120 kg/h Power : 4 Kw Weight :95/110 Kg Dimension : 1000*480*780 mm |

|

|

Capacity : 200-300 kg/h Power : 7.5 Kw Weight :200/230 Kg Dimension : 1050*550*830 mm |

|

|

Capacity : 300-400 kg/h Power : 11 Kw Weight :290/320 Kg Dimension : 1200*560*950 mm |

|

|

Capacity : 400-600 kg/h Power : 15 Kw Weight :320/360 Kg Dimension : 1240*580*1000 mm |

|

|

1) The pressure is larger and adjustable. So it can make more type of pellets such as sawdust, rice husk, straw, cottonseed husk, weeds and all kinds of crop straw and plant waste.

2) Low energy consumption and easy operation. which is especially suitable for small farms in the area of shortage of electricity.

3)Small and lightweight, making small-scale production possible.

4) Please Click to see more detail information of flat die wood pellet press machine . |

|