- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

d02

-

Thickness:

-

0.1MM-10MM

-

Size:

-

1000MM*500000MM

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

weitai

-

Model Number:

-

d02

-

Thickness:

-

0.1MM-10MM

-

Size:

-

1000MM*500000MM

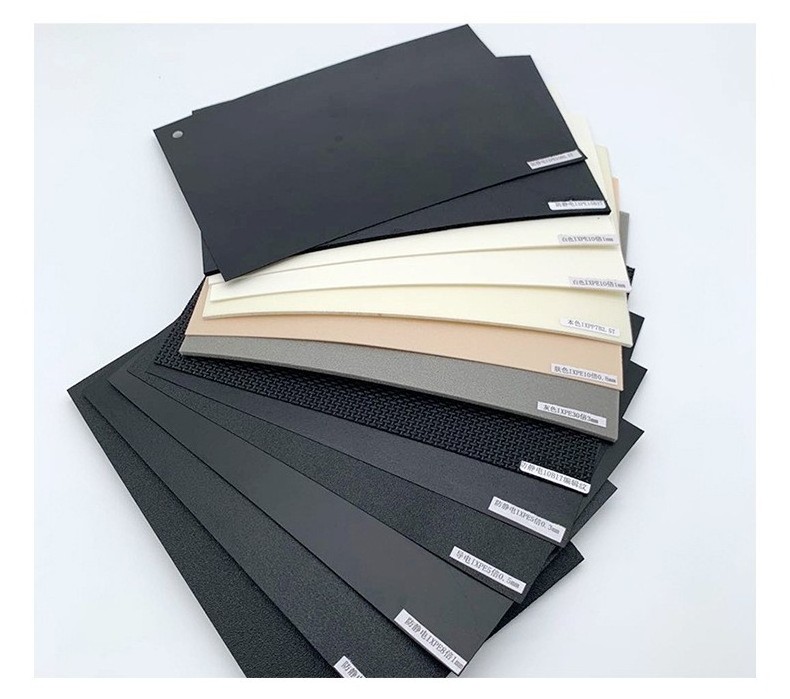

Product Description

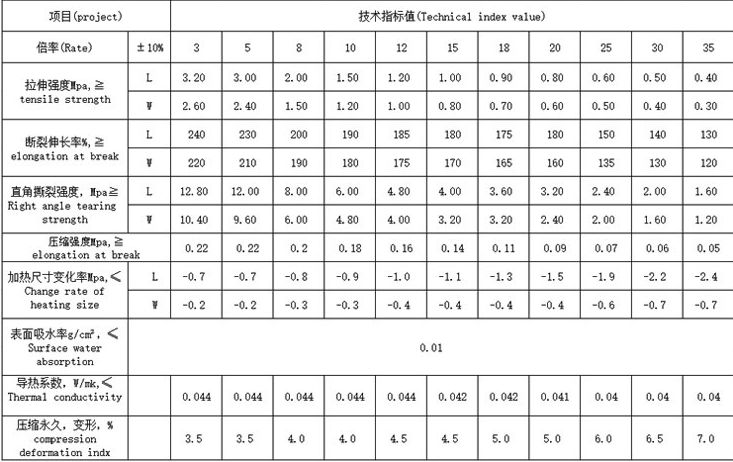

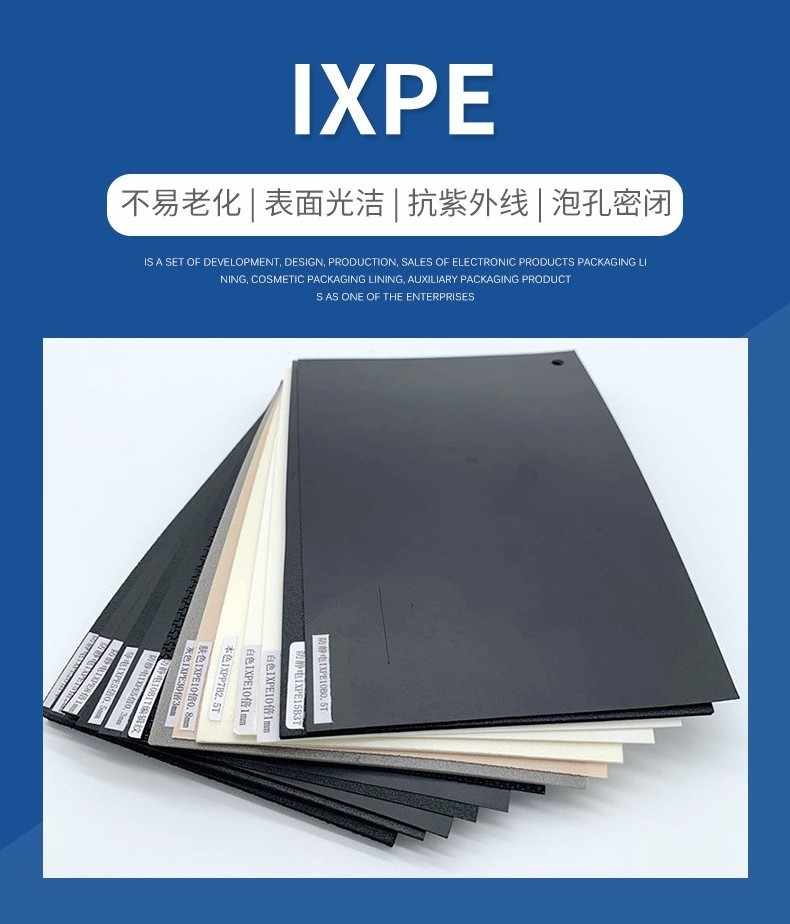

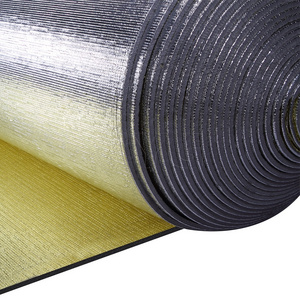

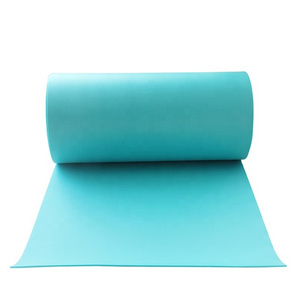

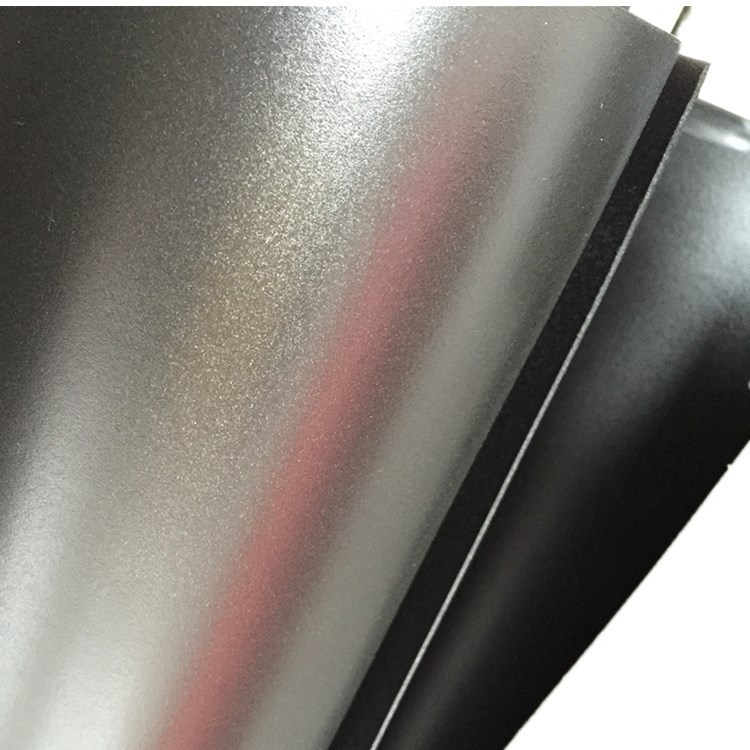

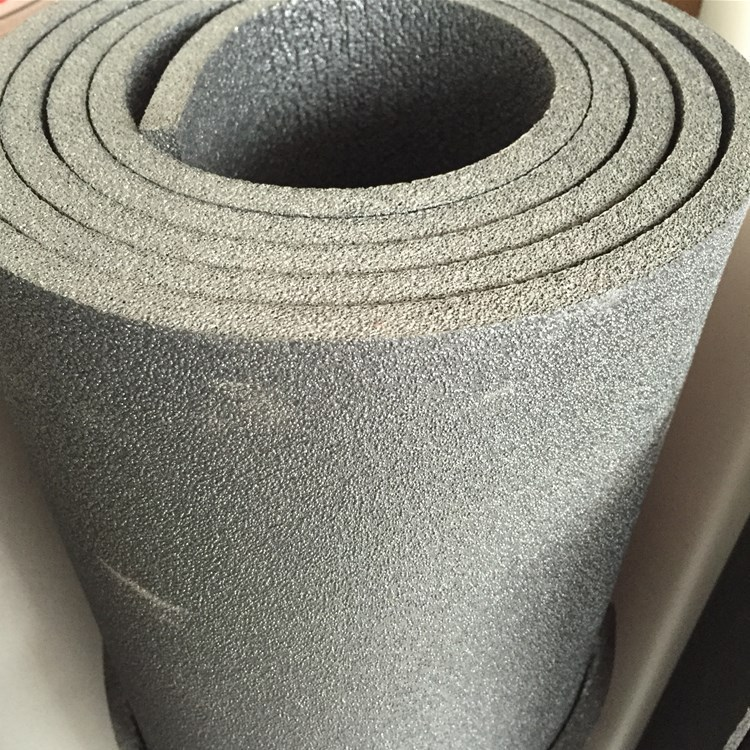

The full Chinese name of XPE (IXPE) is: chemical (physical) cross-linked polyethylene foam sheet, which is a kind of foamed plastic with wide application and excellent performance. The product is a new type of material that uses LDPE (low-density polyethylene) as the main material, bridging with DCP (crosslinking agent), and foaming with AC (azo foaming agent). During the production process, the modification effect can be achieved by adding other materials. XPE (IXPE) is a free form continuous foaming material. A soft material with a smooth surface, sealed pores, independent, uniform, non absorbent, infinite length, and non absorbent properties. Compared with other similar products, XPE (IXPE) has better performance. XPE (IXPE), especially in areas such as environmental protection, flame retardancy, insulation, waterproofing, moisture resistance, shock absorption, cushioning, rebound, insulation, heat insulation, weather resistance, aging resistance, drug resistance, lightweight, easy processing and shaping, and pollution-free, cannot be simultaneously used by other materials (such as EPE, PES, PVC, PEF, PU, NPE, etc.). Therefore, XPE (IXPE) is widely used as an inner core material and outer packaging material in automotive interiors, sports and leisure, tourism products, packaging, freezing, architecture, home decoration, public space decoration, as well as shoe materials, bags, friction materials, agriculture, forestry and aquatic products, marine navigation industry, children's toys, medical care, and so on. Go to various daily necessities industries. The market has enormous potential and broad prospects. XPE (IXPE) production and equipment Ordinary XPE generally uses horizontal furnace foaming, while IXPE can use horizontal furnace foaming or vertical furnace foaming. However, whether it is XPE or IXPE, the front-end and back-end processes are basically the same, and the most common production methods now mainly include: Granulation - extrusion - tablet pressing - foaming - coiling. The commonly used granulation methods include: 1. Internal mixing - Open mixing - Pulling - Cooling - Cutting particles 2. Internal mixing - Single screw extrusion - Water ring (air-cooled) granulation 3. There are three methods: high-speed mixer - parallel twin screw mixing extruder - single screw extruder - water ring (air-cooled) pelletizing. The extruder is a mixed extrusion structure, and due to the raw materials, there are high precision requirements for temperature control, water ring sleeve, heating ring, screw temperature control, etc. of the extruder. The material of the barrel and screw of the extruder currently used is usually 38CNMOACA (chromium molybdenum aluminum) high-quality alloy steel, which adopts XPE material specific structure. The screw core is filled with water or oil, and is equipped with a high-precision constant temperature device. The tablet is formed using an upright three roller calendering machine, which is a mirror parallel roller with a high-precision constant temperature system for internal water supply. There is a six meter cooling bracket at the back, equipped with a trimming knife, and a stress relief device. The foaming furnace adopts the latest reinforced furnace body, with a total length of 17.98 meters, a flat top height of 2.4 meters, and a width of 2 meters. The furnace body is divided into two main parts: cross-linking section and foaming section. Equipped with imported high-precision igniters and heated by liquefied gas (L.G.P), this furnace is characterized by low energy consumption, wide production process, flexible and simple operation, and can produce XPE and IXPE. The product width is 60CM~170CM, and the thickness is 3mm~15mm. IXPE can produce 2.5mm at its thinnest and 7mm at its thickest, with a density of 25KGM3~300KG/M3. The tail of the foaming furnace is equipped with a monitoring system, which can observe the operation status of the mesh belt and the feeding plate. This foaming furnace adopts a mesh belt conveyor motherboard to ensure the continuity and stability of foaming. The winding section has a total length of 20M. It is sequentially processed through a five roll shaping machine, an air cooling system, a surface smoothing processor, an automatic deviation correction and edge cutting device, (other auxiliary equipment can be added as needed) a traction machine, a dual station winding machine, and this set of units has a width of 2M. All cooling and forming rollers are mirror chrome plated or stainless steel rollers, which are durable. The center height of the entire production line is 1.2m, with a total length of 55m. There are three workstations for extrusion, foaming, and coiling, and all equipment covers an area of approximately 120 square meters. Comprehensive performance of XPE and IXPE Chemical cross-linked polyethylene (XPE): Project unit model Times 10000 20000 30000 40000 Apparent density KG/M3 90 50 33.33 25 Hardness: C 40+-5 25+-4 20+-2 14+-2 Tensile strength MPA (transverse) 0.60 0.40 0.24 0.10 MPA (longitudinal) 0.90 0.48 0.30 0.20 Elongation% (transverse) 170 130 100 60 %(Vertical) 180 140 110 80 Tear strength KN/m2 (transverse) 6.0 2.5 1.8 0.9 KN/m2 (longitudinal) 6.5 3.0 2.0 1.0 Compression strength 25% KPA 130 50 40 25 Thermal conductivity WM/K 0.046 0.040 0.034 0.032 Water absorption rate% 0.001 0.001 0.001 Heat shrinkage rate% (transverse) -0.7-1.3-2.0-3.5 %(Vertical) -0.2-0.3-0.5-1.5 Comprehensive properties of electronic cross-linked polyethylene (IXPE) Electronic cross-linked polyethylene (IXPE): Project unit model Times 10000 20000 30000 40000 Apparent density KG/M2 90 50 33.33 25 Hardness: C 40+-5 25+-5 20+-2 14+-2 Comprehensive comparison of technical properties of XPE, IXPE and other foam plastics Project XPE40 times soft PVC foam PS foam PU foam glass sponge rubber foam Thermal conductivity coefficient (W? M.K) 0.038 0.030 0.048 0.041 0.042 0.034 Water absorption rate (mg/cm2) 0.3 1.9-2.7 2.0-2.5 2.25-3.0 No data available at present 1.7 P (g/cm2) 0.030 0.400 0.035 0.030 0.064 0.064 P (g/cm2) -120-100-35-80-70-75-90-135 < 200-40-105 Weathering resistance, no changes after 20 hours of outdoor exposure, severe deformation, shrinkage, severe erosion, instant destruction, severe shrinkage and weathering, no changes, severe deformation, shrinkage MSOI 83 1967 2573 96////>3000 Toxicity index 0.06 0.8 0.10 0.10/////// The combustion performance ranges from V>100mm/min to spontaneous combustion level V<100mm/min V>100mm/min V<100mm/min from V>100mm/min to V<100mm/min Good corrosion resistance, good resistance, poor resistance to concentrated acids, poor resistance to alkalis The economic service life is as long as 15-30 years, so the investment per unit time is low due to poor steam insulation, and a metal protective layer must be added to increase the overall cost. Due to poor fire performance, a fire protection layer must be added, resulting in an increase in overall cost. Due to poor fire insulation, a metal protective layer must be added to reduce the initial investment, which usually results in partial replacement starting from three years, causing duplicate investment. Therefore, the actual investment is actually larger The initial investment is the largest The initial investment is small, usually starting from three years to make partial replacements, resulting in duplicate investments, so the actual investment is actually larger The initial investment is the largest Anti condensation, good, good, good, good, good According to different materials, special adhesives can be used for construction performance, or special hot air welding guns can be used for welding, thermal lamination or hot forming. The processing is very convenient and difficult to process, and the hard shell is fragile and not suitable for complex shapes, which leads to complex construction and is not suitable for complex shapes. Moreover, fiberglass is harmful to human health. Construction is convenient. In terms of insulation pipelines, sulfides generated at high temperatures can easily corrode copper pipes It is not difficult to see from the above list that both XPE and IXPE, in terms of insulation and heat resistance, as well as tensile and tear resistance, especially in terms of environmental protection, are incomparable to similar products. With the development of industry, people's awareness and requirements for environmental protection are becoming stronger and higher, and XPE and IXPE will surely dominate the world. Processing and utilization of XPE and IXPE Due to their performance and characteristics, XPE and IXPE have a wide range of applications, and their processing methods are relatively simple, mainly through several methods such as composite, backing, straight cutting, vertical cutting, punching, vacuum molding, and compression molding. Currently, XPE and IXPE are mainly applied in several fields, including automobiles, air conditioning, luggage, construction, sports and leisure, floating materials, packaging, insulation, children's toys, and other civilian industries. Here are a brief explanation of the most common application areas: The automotive interior industry: XPE and IXPE have been accepted as new materials by major domestic automobile manufacturers, such as Dongfeng's various series of trucks, Fukang, Fengshen Blue, Dongfeng Picasso, Mazda, Toyota, Guangzhou Honda, Changan Ford, Southeast Motors, Changchun FAW, Baolong, Beijing Hyundai, BAIC Foton, Chery, Jinlong Bus, SAIC, etc. Usage in automobiles and several processing methods: Automotive interior door protection panel The door guard board is installed inside the car, and the PP foam plastic board was used previously. Its anti-aging performance and shock absorption and insulation are outstanding, but due to insufficient environmental protection and other performance, it has been replaced by IXPE. Generally, the materials used for interior door guards in cars are IXPE and non-woven PU, which are bonded with self-adhesive, then cut and heated to reach the softening point, and then compressed into shape in a mold. Sun visor Sun visors are a type of frequently moving component, and due to the tendency of previously used materials (such as PU, EPE, EVA, etc.) to deform or weather into powdery foam after prolonged exposure to sunlight, XPE has become the best alternative. Using XPE to process sunshades is mainly achieved by using composite fabrics or films as the surface, and then forming them through hot stamping or cold stamping and hot pressing. The forming effect is better and the appearance is beautiful and generous. Insulation pad The heat generated by the engine of a car has seriously affected its comfort. Due to its excellent insulation and heat resistance performance, XPE was designated as the only processing material for insulation pads by Dongfeng Dahuo 153 series and 145 series vehicles as soon as it appeared. Usually, it is XPE hot composite aluminum film, and then pressed into shape. Floor mat, luggage compartment mat Floor mats and luggage mats are generally made of low magnification XPE and formed by flame composite LDPE molding. Sealing friction parts: Due to its superior resilience and thermal insulation and sound absorption performance, XPE is the preferred material for high-quality sealing and friction. Other vacuum molded parts XPE is an ideal product for protecting other complex components of automobiles due to its convenient processing, easy molding, low thermal shrinkage coefficient, and non deformation. Application in the air conditioning industry Insulation, shock absorption, and sound absorption of central air conditioning ventilation ducts. Air conditioning insulation pipe and drip pipe Shock absorption, sound absorption, and insulation of compressors construction industry Due to the continuous use of EPE felt for waterproofing in the construction industry, it has become a convention. However, due to its insufficient performance, leakage and other problems often occur during short-term use in the construction industry, and the construction is complex and replacement is frequent. Increase both usage and production costs exponentially. XPE is its best alternative, however, a barrier caused by other reasons prevents XPE from smoothly entering the construction industry. However, XPE is still used as waterproofing material in some national key projects. For example: Three Gorges Project, South to North Water Diversion Project, Beijing Metro, Nankai Middle School Swimming Pool, Shuohuang Railway Tunnel Project, Shenzhen Municipal Party School, Beijing Dongcheng People's Committee Community, Tianjin Jinyao Square Underground Garage, Zhengzhou Power Tunnel Project, and so on. Application in the sports industry The application of XPE and IXPE in the sports industry is relatively early and common, with mature processes. For example: sports treads, handles, horizontal mats, clamps, and various molded parts. The application of XPE and IXPE in the footwear and luggage industry In the shoe and luggage materials industry, EPE and NPE were the earliest to be used in China. However, due to insufficient tear strength and poor rebound of EPE, as well as the odor and aging resistance of NPE, the quality of products cannot be improved. With China's further development as a world factory, exports have become a business focus for many enterprises. However, products that use EPE and N PE as inner core materials have been rejected, and seeking new alternatives has become an urgent task. The emergence of XPE and IXPE means that all problems are no longer problems. The application of XPE and IXPE in the construction industry The application of XPE and IXPE in the construction industry is mainly due to their waterproof, moisture-proof, sound insulation, lightweight and flame retardant properties, aesthetics, and convenient construction. XPE and IXPE, as substitutes for EPE and oil felt, can be used for roof waterproofing and leakage prevention, and can extend the service life by 1.5 times compared to EPE oil felt. XPE and IXPE can also be used for foundation waterproofing, wall sound insulation, wall beautification, and sound insulation. Especially in the nursery and restroom, the excellent performance of XPE and IXPE is fully demonstrated. Application of XPE and IXPE as Floating Materials, Toys, and Leisure Industries XPE and IXPE, as floating materials, fully utilize their quality, non water absorption, environmental friendliness, and non deformation properties. XPE and IXPE can be processed into beautiful life jackets, swimming rings, leisure kayaks, and more. XPE and IXPE, as toy substrates, make full use of XPE and IXPE's environmental friendliness, easy molding, diverse colors, non deformation, and especially their non-toxic and harmless properties. The application of XPE and IXPE in the sports and leisure industry utilizes their beautiful appearance, diverse colors, lightweight, portable, environmentally friendly, and health benefits.

Hot Searches