- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Name::

-

LYA-B1 Manual Clay Brick Machine

-

Weight::

-

200-230kg

-

Molding cycle::

-

25-30s

-

Color::

-

according to your needs

-

Worker::

-

1~2staff

-

Main market::

-

Global

-

Raw material::

-

Clay, soil, cement, sand ,water. etc.

Quick Details

-

Type:

-

Interlock Clay Block Making Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

100-110PCS/h

-

Place of Origin:

-

Henan, China

-

Name::

-

LYA-B1 Manual Clay Brick Machine

-

Weight::

-

200-230kg

-

Molding cycle::

-

25-30s

-

Color::

-

according to your needs

-

Worker::

-

1~2staff

-

Main market::

-

Global

-

Raw material::

-

Clay, soil, cement, sand ,water. etc.

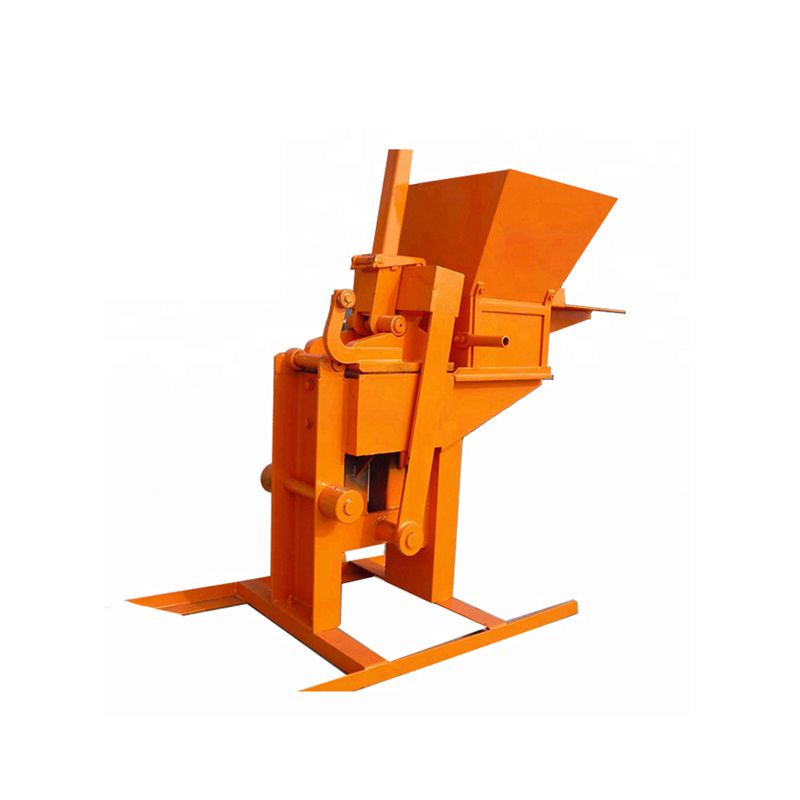

Hydraulic manual concrete hollow block paver brick making machine

Product Description

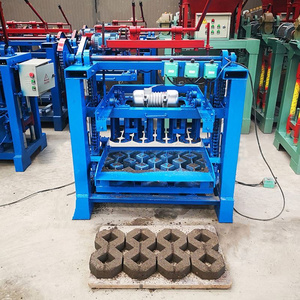

This machine used to make the clay hollow blocks with size of 240*115*75mm; 250*115*100mm; 300*150*100mm;the block size can be changed by updating the related molds,material can be as clay ,soil,or even concrete. This manula press brick making machine can meet the brick requirement of small construction engineering, is the best selection of small scale brick factory or mobile brick factory. The finished bricks is widely used in buildings, road paving, squares, gardens, landscaping, city constructions etc. It is populared in tanzania,kenya,ghana,ethiopia etc.

| LYA-B2 Specification of Manual Interlock brick machine | |

| Machine Type | LYA-B1 Manual Clay Brick Machine |

| Dimension | 600*4 5 0* 1000 mm |

| Forming cycle | 15 -3 0 S econds |

| Brick size | Customized available |

| Material | Cement;Clay/Mud/Earth;Fly ash |

| Power | Manual operation |

| Operating staff required | 1~2 staff |

| Total weight | 200-230kg |

| Capacity | 1Pcs each Pressing |

| Color | Customized |

| Production(Pcs/h) | 100 ~1 1 0 |

| Warranty | 1 Year |

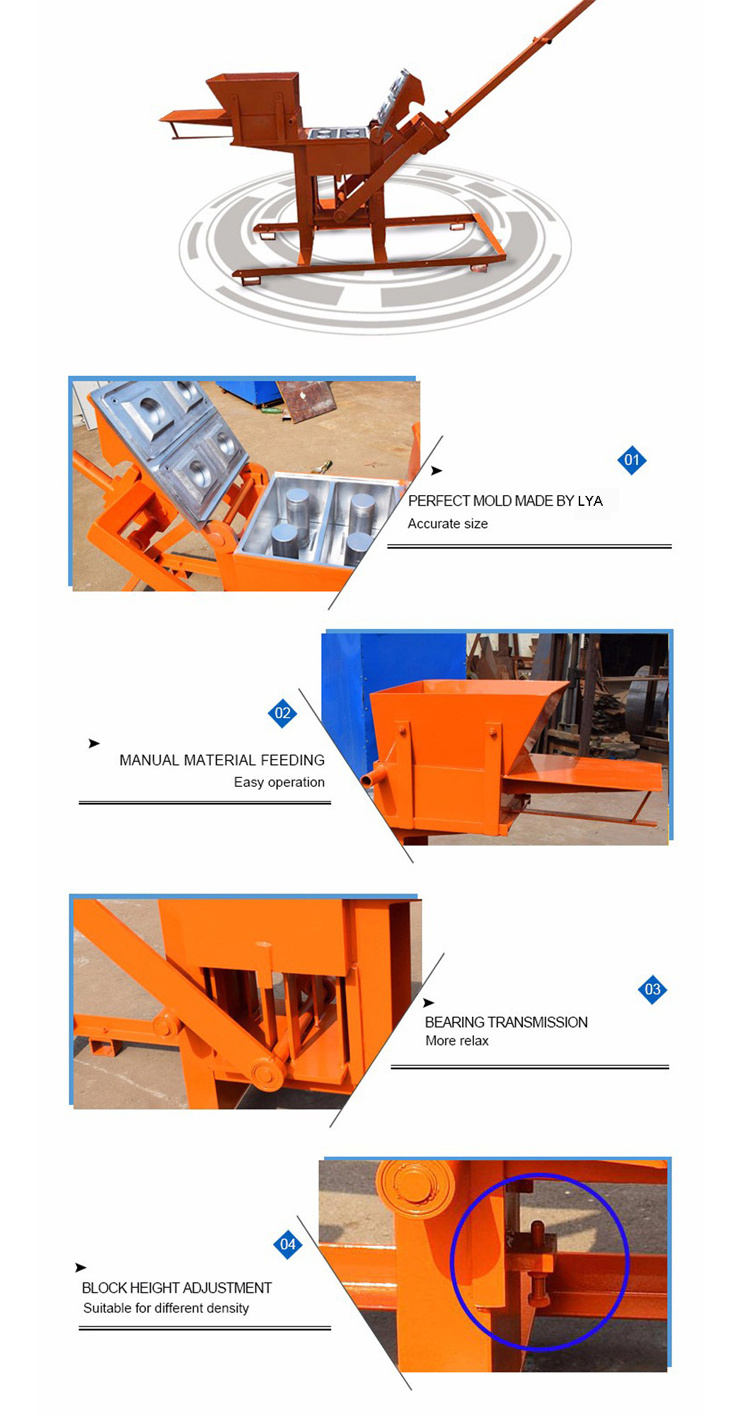

Working Process:

Put enough raw material into the feeding box by spade or just hand,then the move open the pressing head,move the

box above the mould box ,let the raw material drip in the mould box,when it is almost full,just shave the material box to make the mould box load fully.Then close the pressing head,you need press the material inside by manpower,after finished ,you can take the blocks out on the shelf for drying.

One set mould included with the machine,engineers will give one fully operational instruction for reference.Before shipping,we will do trial producing for you, and the video will be sent for confirmation.we also have the diesel engine model,can do customization for customers.

Advantages

1) Easy Operation. This machine can be operated by any workers just by short-time learning.

2) High-efficiency. With low consumption of material,every brick can be made in 30- 40s,which will ensure a quick production and good quality.

3) Flexibility. QMR2-40 is with a small body size,so it can cover less land area.Moreover, it can be moved from one to another place easily.

4) Environment-friendly. This brick machine works without any fuels just under operation of human.

5) Worth for your investment. Compared with other bigger machines,QMR2-40 can take little cost and return you a good output.

6) Adjustable. Can produce different height of briks across adjusting the bolt under the mould.

7) Made under strict quallity control. Each of our machine needs to be tested as a qualified product before leaving factory.