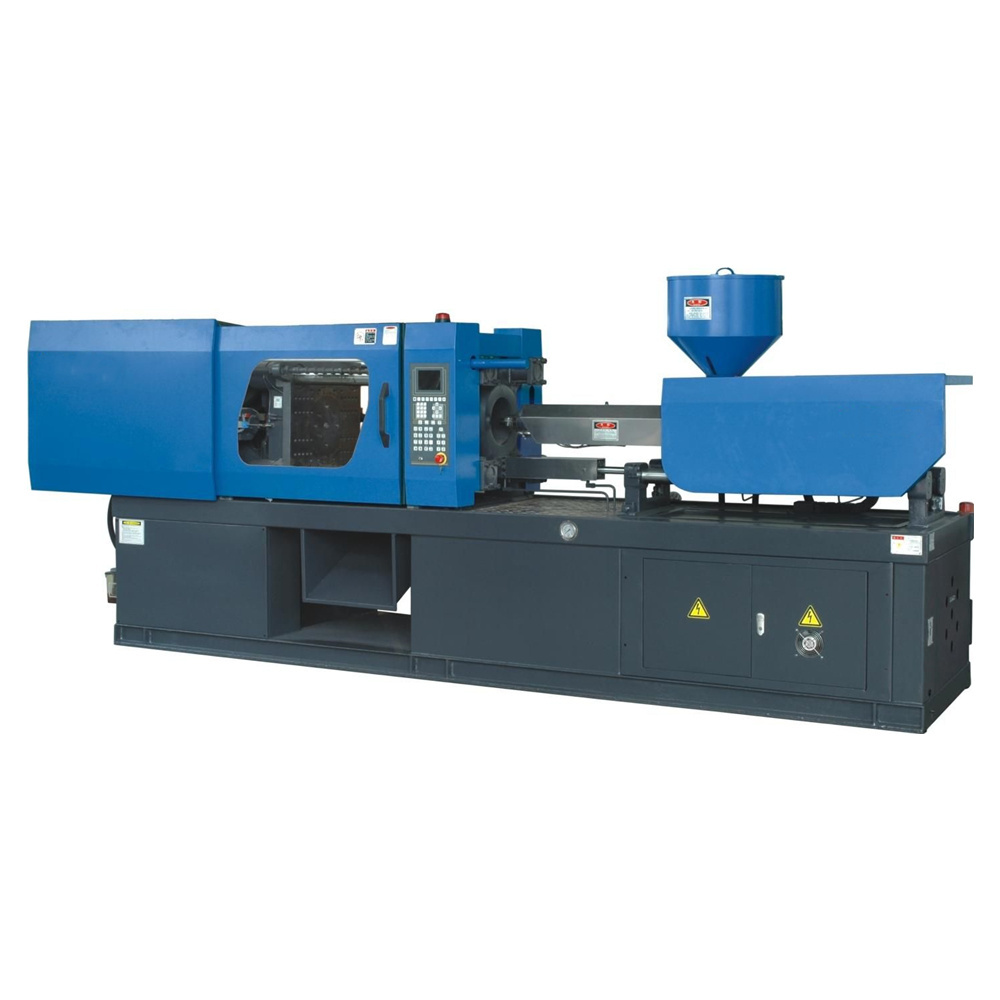

- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

150 - 420 mm

-

Ejector Stroke(mm):

-

80 mm

-

Ejector Force(kN):

-

1400 kN

-

Theoretical Shot Volume(cm³):

-

113 cm³

-

Injection Rate (g/s):

-

95.1 g/s

-

Injection Weight (g):

-

230 g

-

Screw diameter (mm):

-

38.4 mm

-

Weight (KG):

-

4.2 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

SZ-1400A

-

Brand Name:

-

SMAC

-

Power (kW):

-

11 kW

-

SCREW Diameter:

-

38.4mm

-

injection rate:

-

95.1g/'s

-

shot weight:

-

230/252g

-

clamp tonnage:

-

1400kn

-

mould thickness:

-

150-420mm

-

space between tie-bars:

-

428*386mm

-

ejector stroke:

-

140mm

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

38.4mm

-

Distance between Tie Bars(Height)(mm):

-

38.4mm

-

Plasticizing Capacity(g/s):

-

95.1

-

Mold Height(mm):

-

150 - 420 mm

-

Ejector Stroke(mm):

-

80 mm

-

Ejector Force(kN):

-

1400 kN

-

Theoretical Shot Volume(cm³):

-

113 cm³

-

Injection Rate (g/s):

-

95.1 g/s

-

Injection Weight (g):

-

230 g

-

Screw diameter (mm):

-

38.4 mm

-

Weight (KG):

-

4.2 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

SZ-1400A

-

Brand Name:

-

SMAC

-

Power (kW):

-

11 kW

-

SCREW Diameter:

-

38.4mm

-

injection rate:

-

95.1g/'s

-

shot weight:

-

230/252g

-

clamp tonnage:

-

1400kn

-

mould thickness:

-

150-420mm

-

space between tie-bars:

-

428*386mm

-

ejector stroke:

-

140mm

Recommend Products

Product Description

1.High position accuarcy:most suitable for machining parts such as dies,drilling or boring jigs and fixtures

2.wider range of application:drilling, boring, medium-load milling, scribing,scaling and measuring all are ok

3.various sizes of table:three standard sizes and much more amounts of size just as your requirement

2.wider range of application:drilling, boring, medium-load milling, scribing,scaling and measuring all are ok

3.various sizes of table:three standard sizes and much more amounts of size just as your requirement

1. Do a good job in publicity and education, make operators and maintenance workers conscientiously record, count and analyze the faults of injection molding machine, and put forward reasonable suggestions.

2. Closely combined with the actual production of injection molding and the characteristics of injection molding machine, the injection molding machine in use is divided into three categories: A, B and C, so as to determine the focus of fault management.

3. Use monitoring instruments to monitor the key parts of the key injection molding machine in a planned way, and timely find the signs of failure and deterioration information.

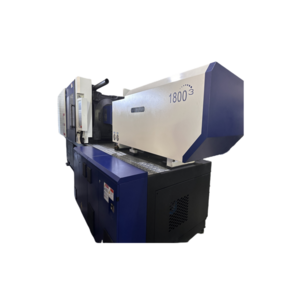

Plastic injection molding machine is also called plastic injection molding machine or plastic injection machine. It is the main molding equipment to make thermoplastic or thermosetting materials into various shapes of plastic products by plastic molding mold. Divided into vertical, horizontal, all electric. The plastic injection molding machine heats the plastic and applies high pressure to the molten plastic to make it eject and fill the mold cavity

Specifcation

|

model

|

units

|

HL-1000A

|

HL-1320A

|

HL-1400A

|

HL-1650A

|

HL-1800A

|

HL -2050A

|

|

SCREW Diameter

|

mm

|

36.38

|

38.4

|

38.4

|

42.45

|

45.48

|

45.48

|

|

injection rate

|

g/'s

|

90.95

|

95.1

|

95.1

|

135.155

|

142.16

|

140.159

|

|

shot weight

|

g

|

128/162

|

188205

|

230252

|

286/326

|

335/375

|

415/472

|

|

clamp tonnage

|

KN

|

1000

|

1320

|

1400

|

1650

|

1800

|

2050

|

|

mould thickness

|

mm

|

150-420

|

150-420

|

150-420

|

170-440

|

180-470

|

190-470

|

|

space between tie-bars

|

mm

|

385*350

|

410*375.

|

428*386

|

455*425

|

480*460

|

490*464

|

|

ejector stroke

|

mm

|

125

|

135

|

140

|

155

|

155

|

155

|

|

ejector tonnage

|

KN

|

50

|

50

|

50

|

70

|

70

|

70

|

|

hole diameter

|

mm

|

100

|

100

|

100

|

125

|

125

|

125

|

|

total weight

|

t

|

3.4

|

3.9

|

4.2

|

5

|

5.5

|

6

|

Hot Searches