NO.1 Feeding Section:

High speed and precise lead edge feeder.absolute minimal marking to sheet. Air volumecontrol adjustable to different grades handled.vacuum surface area variable subject to

sheet size.

1)

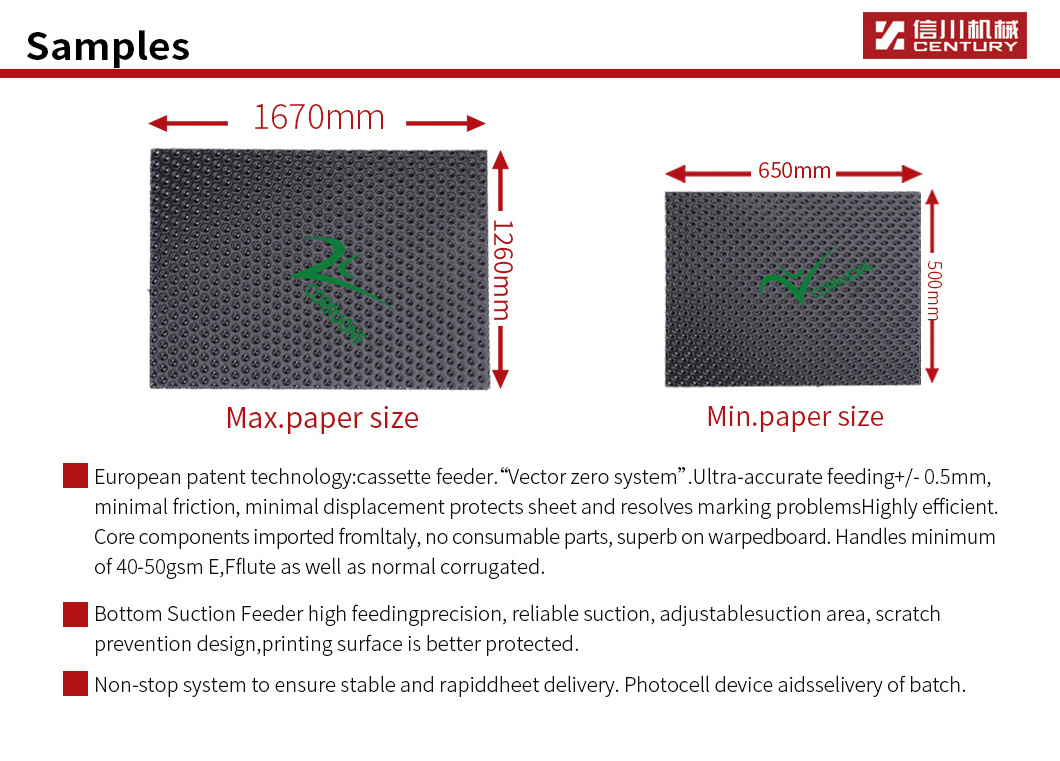

European patent technology:cassette feeder“Vector zero system"Ultra-accurate feeding+/- 0.5mm, minimal friction, minimal displacement,protects sheet and resolves marking problems.Highly efficient. Core components imported from ltaly, no consumable parts, superb on warped board. Handles minimum of 40-50gsm E,Fflute as well as normal corrugated.

2)

Bottom Suction Feeder high feeding precision, reliable suction, adjustable suction area, scratch prevention design,printing surface is better protected

NO.2

Die Cutting Section:

1)

Efficient pneumatic locking system for chase.Computerised control display with 3D touchscreen, allowing instant machine status reading and error indentification.

NO.3

Stripping

Section

1)

Double action movement with upper and lower stripping frames, motorised upper frame with hoist.Male and female boards inserted subiect to desired job. Right, left, rear and internal stripping function to optimise stripping. Centralised positioning to reduce downtime on stripping set-up.

NO.4

Delivery Section

1)

Adopt the pallet collection paper, flexible and comfortable,to increase the work efficiency.Adopt photoelectric detection to insure smooth and steady delivery.

2)

Non-stop system to ensure stable and rapid dheet delivery.Photocell device aids selivery of batch .

![[JT-MHC1500B] CE Certificate Automatic Creasing and Die Cutting Machine Die Cutter Flexo Printer Slotter Die Cutting Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/7b1d5aadf6363b469fe6fab9aef50a7c.jpg!/rotate/180/sq/300)