- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Best Machinery

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

6500*1300*1100

-

Weight:

-

4500 kg

-

Warranty:

-

5 years

-

Name:

-

Double Layer Making Roll Forming Manufacturing Machine

-

Raw material:

-

Galvanized Sheet

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Cr12 Steel Quenched

-

Cutting type:

-

Hydraulic Cutting

-

The shaft:

-

75mm Solid

-

Cutting blade material:

-

Cr 12 Mov

-

Usage:

-

Metal Roofing Sheet Double Layer Making Roll Forming Machine

-

Main structure:

-

350H steel

-

Screen:

-

Color touch screen

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

4-8m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Best Machinery

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

6500*1300*1100

-

Weight:

-

4500 kg

-

Warranty:

-

5 years

-

Name:

-

Double Layer Making Roll Forming Manufacturing Machine

-

Raw material:

-

Galvanized Sheet

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Cr12 Steel Quenched

-

Cutting type:

-

Hydraulic Cutting

-

The shaft:

-

75mm Solid

-

Cutting blade material:

-

Cr 12 Mov

-

Usage:

-

Metal Roofing Sheet Double Layer Making Roll Forming Machine

-

Main structure:

-

350H steel

-

Screen:

-

Color touch screen

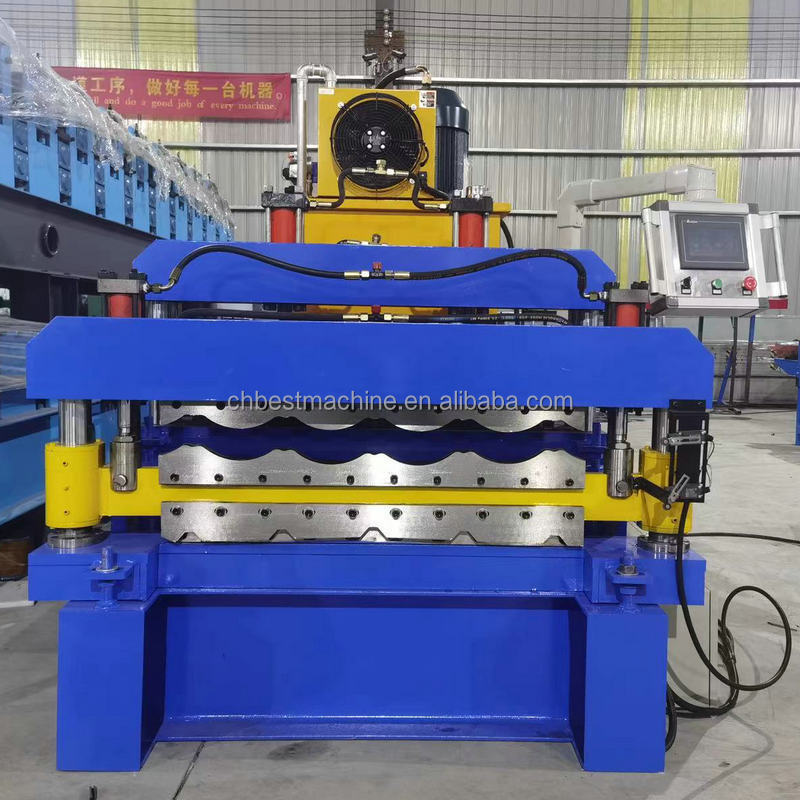

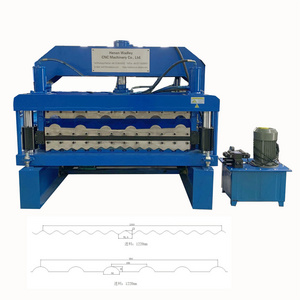

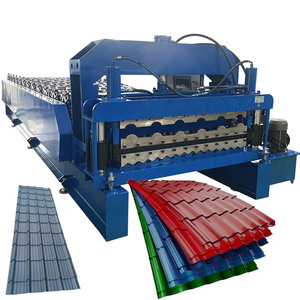

Metal Roofing Sheet Double Layer Making Roll Forming Manufacturing Machine

Double tile press make two models unifies in together perfect, it has reasonable structure, beautiful appearance and its characteristic is saving floor space, simple operation, especially suitable for small venues and site construction customers to use.

This machine is mainly composed of passive feeding outfit, molding main engine, molding cutting device, hydraulic station and computer control cabinet. .

|

Item |

Parameter |

|

|

Suitable Material |

Type |

PPGI/GI/PPGL |

|

Thickness |

0.3-0.8mm |

|

|

Wide |

914mm/1000mm/1200mm/1250mm/1450mm |

|

|

Yield Strength |

230~550MPA |

|

|

Product Specs |

Profile |

Customized profile |

|

Effective width |

Base on customized profile |

|

|

Length |

Any length |

|

|

Power Specs |

Voltage |

380V/3PH/50HZ, accept customization |

|

Main Motor |

5.5kw |

|

|

Hydraulic motor |

4kw |

|

|

Hydraulic pressure |

10-12MPa |

|

|

Machine Specs |

Forming steps number |

13~20 steps |

|

Shaft Material |

45 # steel tempered, Φ70~ 90mm |

|

|

Roller Material |

45 # steel chrome coated |

|

|

Main machine body |

350# H steel welded |

|

|

Transmission |

Chain and Sprocket, chain size 1.5 inch |

|

|

Wall Plate |

16mm thickness |

|

|

Blade material |

Cr12 mould steel with quenched treatment 60-62 ° |

|

|

Forming Speed |

8-12m/min for standard solution |

|

|

Cutting system |

Length-set cutting after roll formed and could pre-cutting to switch off the coils |

|

|

Control System |

Delta PLC and Inverter |

|

|

Manual decoiler |

Max width of coiling: 1000~1450mm Max weight of loading: 5000kg |

|

|

Output Supporter |

2 Pcs Simple Supporter |

|

|

Dimension of the machine |

7.5m~11m×1.5mm×1.2m |

|

|

Weight of the machine |

3.5 ton ~6 ton |

|

Metal Roofing Sheet Double Layer Making Roll Forming Manufacturing Machine pics;

Metal Roofing Sheet Double Layer Making Roll Forming Manufacturing Machine loading and shipping pics:

Other products:

Contact me by WHAT'S APP:008618717894416Your satisfaction and recognition is the goal of our efforts!