- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

FLW

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

16000*1500*2500mm

-

Weight:

-

3500 KG

-

Name:

-

Pvc Profile Making Machine

-

Raw material:

-

PVC Powder

-

Inverter:

-

ABB

-

Product name:

-

pvc corner bar

-

Contactor:

-

simens

-

Temperature control:

-

Omron Brand

-

Extruder:

-

SJ 65/132

-

Speed:

-

1-6m/min

-

Width:

-

18-22MM

-

Cooling way:

-

Water Recycling

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

FLW

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

16000*1500*2500mm

-

Weight:

-

3500 KG

-

Name:

-

Pvc Profile Making Machine

-

Raw material:

-

PVC Powder

-

Inverter:

-

ABB

-

Product name:

-

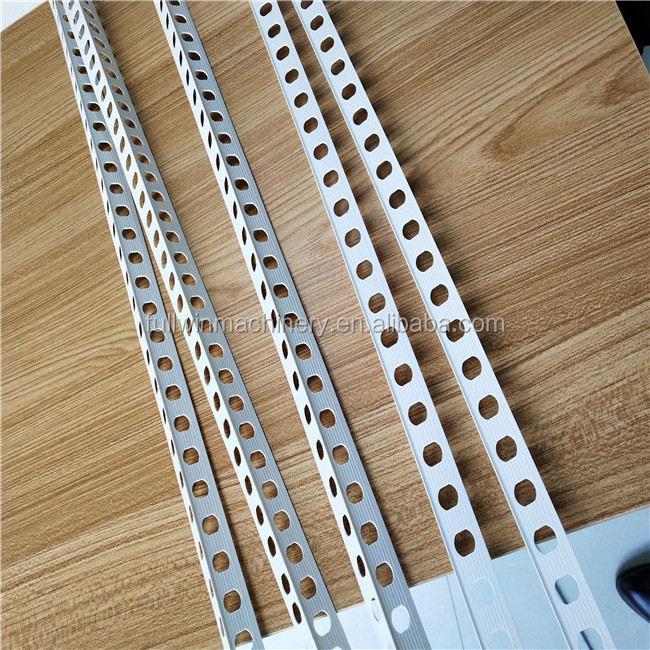

pvc corner bar

-

Contactor:

-

simens

-

Temperature control:

-

Omron Brand

-

Extruder:

-

SJ 65/132

-

Speed:

-

1-6m/min

-

Width:

-

18-22MM

-

Cooling way:

-

Water Recycling

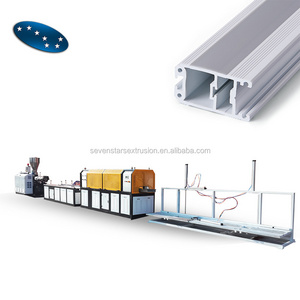

Protect Wall Angel Plastic PP PVC Corner Bead Trim Angel Profile Extrusion Machine Making Production Line

Application: it is installed for wall which in hospitals, kindergartens, hotels, hotels, nursing homes, welfare homes, clubs, airports, office buildings and other public places.To protect children's safety, prevent pets from damaging corners, prevent corner bumping, and can also be used to pack and support.

Machine list of pvc corner border extrusion line

|

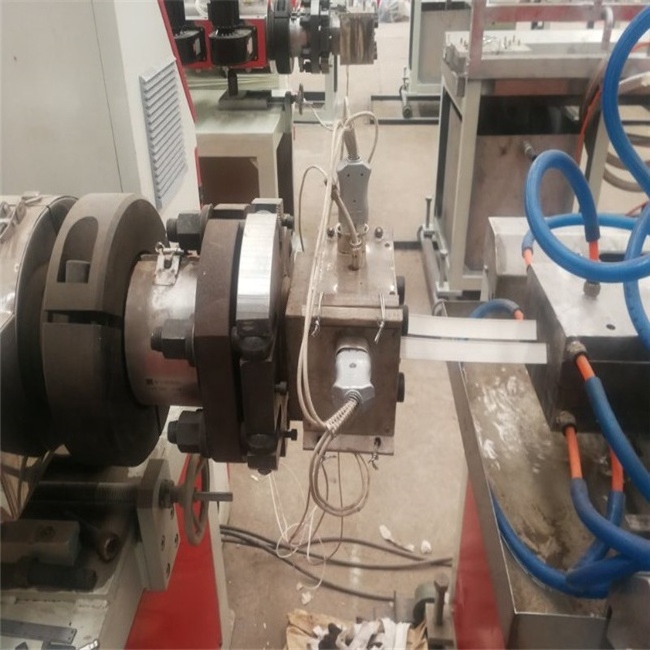

1. Double or single screw extruder |

one set |

|

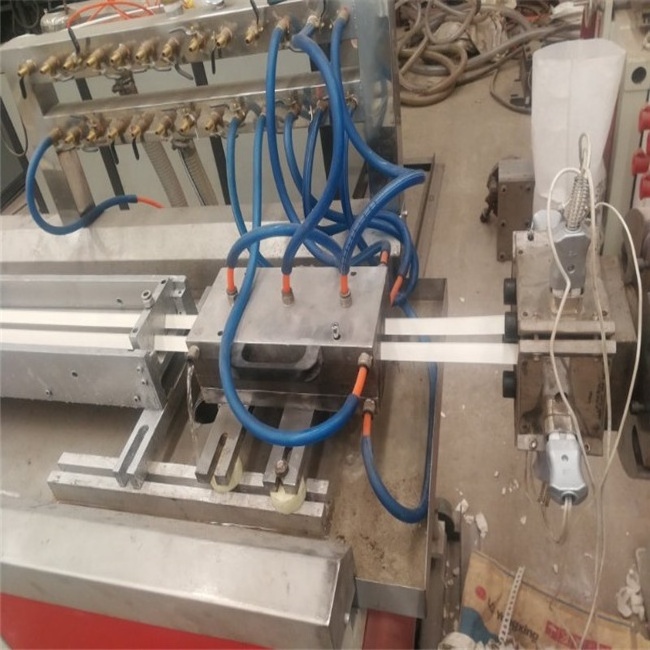

2. mould |

one set |

|

3.water tank |

one set |

|

4.Haul-off machine |

one set |

|

5.cutter machine |

one set |

|

6.stacker |

one set |

- Packaging Details

- film and then wooden box packaging for PVC corner bead extrusion line

Pre-sale services:

Based on the clients' request and budget, we will offer equipment pictures, working site videos, plant processing diagram, assemble drawings, foundation drawings, and plant layout. Clients are welcome to visit our factory, also our equipment working site from former clients.

Sale services:

Our experienced technicians are available on the phone also the Internet, clients can get instance guidance by telephone, email, online service anytime and anywhere.

After-sale services:

Normally, the equipment warranty is 12 months since installation. To establish long term cooperation, we will regularly call and email our clients to check the equipment working condition and offer suggestions for maintenance.

How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

Can I operate machine if don ’ t have experienced engineers?

(1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

Any quality checking before shipment?

100% confirm, run and test machines before shipment with quality certificate.

How long is the guarantee?

12 months since the first day customer operates (except wear parts)

How can u help us when face some technical problem?

24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Where can we get spare part?

we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.