- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BLP

-

Model Number:

-

G01

-

Technique:

-

Clear Glass

-

Width:

-

1650mm

-

Length:

-

>1650mm

-

Transmittance(5mm):

-

>92%

-

Strain point (°C):

-

521±10

-

Softening point (°C):

-

830±10

-

Coefficient of thermal expansion:

-

3.3±0.1*10-6

-

Flexure strength:

-

24Mpa

-

Knoop hardness:

-

480

Quick Details

-

Application:

-

Workshop, Kitchen, Home Office, Hospital, Machine

-

Usage:

-

Industrial

-

Thickness:

-

2mm-19mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BLP

-

Model Number:

-

G01

-

Technique:

-

Clear Glass

-

Width:

-

1650mm

-

Length:

-

>1650mm

-

Transmittance(5mm):

-

>92%

-

Strain point (°C):

-

521±10

-

Softening point (°C):

-

830±10

-

Coefficient of thermal expansion:

-

3.3±0.1*10-6

-

Flexure strength:

-

24Mpa

-

Knoop hardness:

-

480

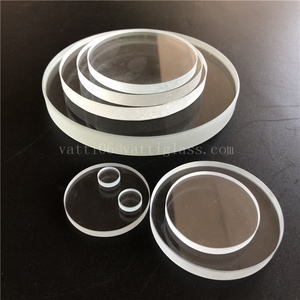

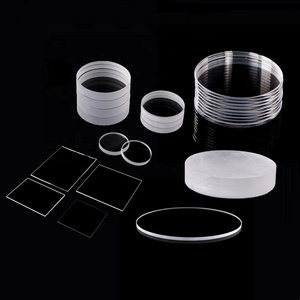

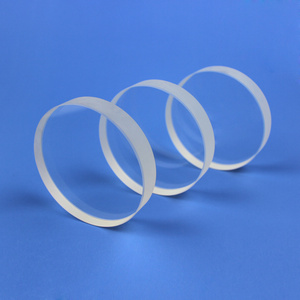

Telescope Mirror Blanks

Based on customer actual need to cut into small pieces for sale

Reverse side: protective or frosted edge down side;

Chamfering: protective chamfering or fillet

Hot bending: round hot bending or hot bending into perspective;On the surface of printing

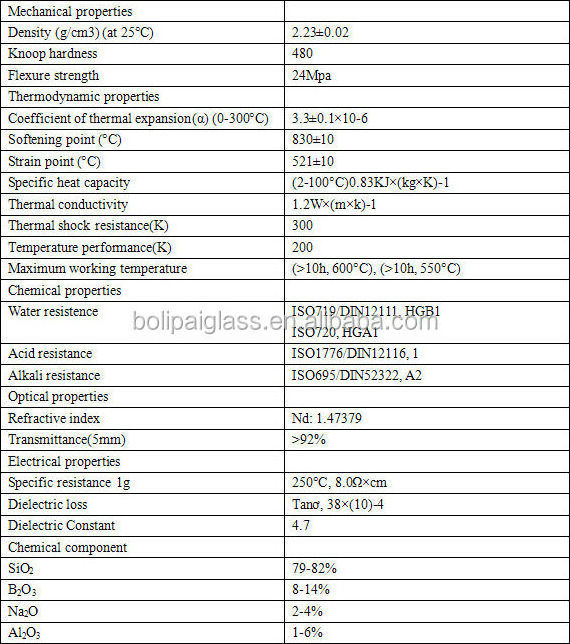

Borosilicate glass has excellent chemical and thermal-shock resistance and has a maximum working temperature of 500°C so are excellent for use in high powered light source applications or an excellent choice for cold and hot mirror substrates.

High temperature load capacity:

- up to 550 ° C permanent load

- up to 600 ° C temporarily (< 10h)

Low thermal coefficient of expansion

Thermal coefficient matches silicon

(anodic bonding)

High thermal shock resistance

Clear, practically colorless appearance

Low fluorescence

High UV-Transmission

High chemical resistance against acids,

bases and organic substances

Low alkali content in the glass composition

Low specific weight

BOROSILICATE FLOAT GLASS 3.3 application

Substrates for dielectric coatings

Lighting applications

Optical filter coating substrates

Wafer substrates

Anodic bonding applications

Biotechnology

Photovoltaics

Environmental technology

Harsh environments

Neutron absorbers

pyrex glass baking tray

Measurement and sensor technology

Any enquires, please feel free to contact me ;)