- Product Details

- {{item.text}}

Quick Details

-

Power:

-

60 kW ( Oil burner)

-

Dimension(L*W*H):

-

8300x4000x5500mm

-

Weight:

-

12 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

30 t/h

-

Power(Oil burner):

-

60 kw

-

Power(Coal burner):

-

92 kw

-

Oil consumption:

-

5-7.5 kg/t

-

Coal consumption:

-

13-15 kg/t

-

Production temperature:

-

120-180 degree celsius adjustable

-

Model:

-

LBY-30B

-

Certification:

-

ISO 9001:2008

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DKTEC

-

Voltage:

-

to be confirmed

-

Power:

-

60 kW ( Oil burner)

-

Dimension(L*W*H):

-

8300x4000x5500mm

-

Weight:

-

12 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

30 t/h

-

Power(Oil burner):

-

60 kw

-

Power(Coal burner):

-

92 kw

-

Oil consumption:

-

5-7.5 kg/t

-

Coal consumption:

-

13-15 kg/t

-

Production temperature:

-

120-180 degree celsius adjustable

-

Model:

-

LBY-30B

-

Certification:

-

ISO 9001:2008

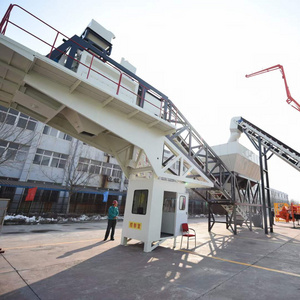

1. Integrated design of drying and batching drum, reduce initiate cost for customer

2. Simple structure, easy operation, drying while drum rotate in counter-clockwise direction (from burner), discharging while drum rotates in clockwise direction(from burner), and the wind are swirled in the center of the drum

3. PLC control, touch screen, auto/manual switchable o Towing chassis for easy transport and installation

4. Burner is available for coal and oil, at customer's option

|

Model No |

LBY-8 | LBY-10 | LBY-15 | LBY-20 | LBY-30B | |

| Capacity | 8t/h | 10 t/h | 15t/h | 20t/h | 30t/h | |

| Power | Oil burner | 24kw | 25 kw | 36kw | 49kw | 83kw |

| Coal burner | 40kw | 43 kw | 56kw | 73kw | 86kw | |

| Production temperature | 120-180° adjustable | |||||

| Fuel consumption | Oil burner | 5-7.5 kg/t | ||||

| Coal burner | 13-15 kg/t | |||||

| Optional |

Coal miler ,Water dust filter,Bitumen tank,Control room |

|||||

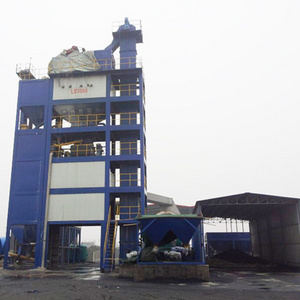

Auto Production Line

1, Integrated design of drying and batching drum, reduce initiate cost for customer

2. Aggregate Feeding

3. Aggregate discharged into drying drum

4. Mineral aggregates are continuously lifted in the drying drum, forming "material curtain", and conducting

intensive heat exchange with the flame of the burner And aggregate is conveyed into the its elevator

5. Hot aggregate discharged to mixer drum, LBY series adopts filer elevator making filler get into mixer drum.

Then the more aggregate is lifted and discharged Into arying arum

6. mineral aggregates, filler and bitumen are continuously lifted and uniformly mixed in the mixer drum. The drying

drum and aggregate's elevator continuously cle work

7. Asphalt Discharge: Mixer drum ends mixing after hot mineral aggregates being uniformly bound finished

product material is discharged out

8. If there is the storage silo, finished product material is lifted by its elevator to its storage silo and disc harged into

the storage silo and then stored

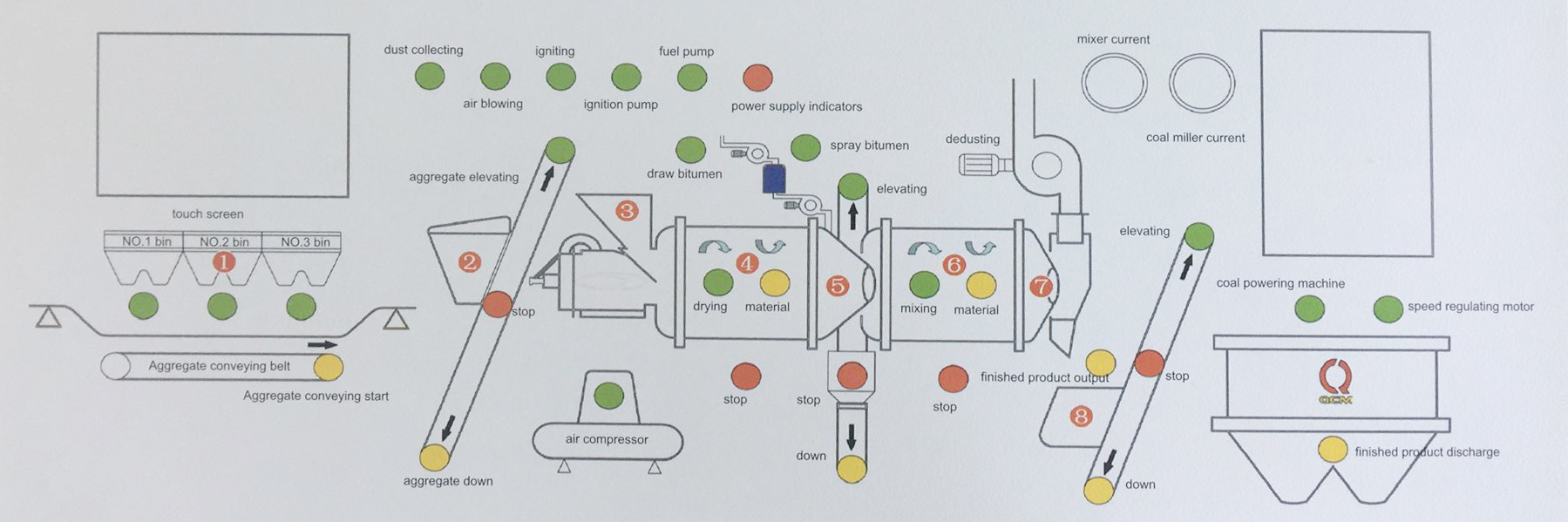

Packing & Delivery

♦

Pre-Sales Service

♦

After-Sales Service

* Inquiry and consulting support. * Training how to install / use the machine.

*Technical information provide. * Good and fast arrangement for the shipment

* Price offer with detail configuration. * Engineers available to service machinery overseas.

♦

Strong logistics

Not only take care of your products,but also get fastest shipment to reach lead time;

♦

Wholehearted service

Not only complete order process,but also provide professional consultation

A bout us

Hangzhou Dongkun Technology Co.,Ltd( DKTEC) supply concrete mixing plant, asphalt mixing plant, crusher plant relevant equipment. We have advantage in providing complete spare parts & accessory solution for all above plant. We have our own brand DKTEC & COMACO.

We aim to be your plant guardian.

Concrete batching plant Asphalt mixing plant Jaw crusher