- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XL2626

-

Keywords:

-

Double process gun nail machine

-

Function:

-

nailing and cutting

-

Material:

-

wooden

-

Brand:

-

EASTMAC

-

Inverter:

-

square7.5KW

-

Spindle speed:

-

2800r/min

-

Efficiency:

-

(20 ~ 60) s / piece

-

Control system:

-

PLC+ touch screen

-

Threading hole distance Center:

-

(150 ~500) mm

Quick Details

-

Usage:

-

processing

-

Place of Origin:

-

Anhui, China, China

-

Brand Name:

-

EASTMAC

-

Model Number:

-

XL2626

-

Keywords:

-

Double process gun nail machine

-

Function:

-

nailing and cutting

-

Material:

-

wooden

-

Brand:

-

EASTMAC

-

Inverter:

-

square7.5KW

-

Spindle speed:

-

2800r/min

-

Efficiency:

-

(20 ~ 60) s / piece

-

Control system:

-

PLC+ touch screen

-

Threading hole distance Center:

-

(150 ~500) mm

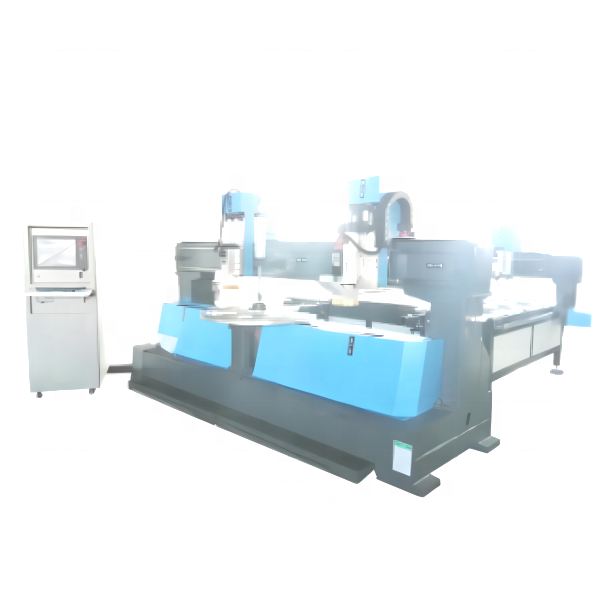

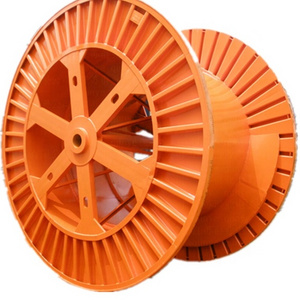

Double process gun nail machine/Wood Cable R eel Processing Equipment

Main Technical Data:

|

Specification |

XL2 626 |

|

Motion positioning accuracy |

±0.0 5 /300mm |

|

Repeatability |

0.02mm |

|

Maximum machining diameter |

2 6 00× 2600 × 350 mm |

|

Workbench clamping method |

Cylinder processing and positioning |

|

Spindle motor power |

7.5KW/ER32 |

|

nail gun |

CN80/CN100 |

|

Control System |

Zotyk Gun Nailer System |

|

X/Y/Z axis guide |

Taiwan imported PMI rectangular linear rolling guide |

|

X/Y axis transmission mode |

Helical gear + planetary reducer |

|

Z-axis transmission mode |

TBI2510 Ball screw rod |

|

Drive System |

Servo system |

|

Inverter |

square 7.5KW |

|

main control box |

Zotec cable reel machining center system |

|

Machine lubrication and maintenance |

automatic lubrication system |

|

Operating Voltage |

20m/min |

|

Operating Voltage |

42 0V/50Hz |

|

Overall dimension ( long* wide*high ) |

3700x3300x1700 |

Pallet Packing, Wooden Packing, Vaccum Packing are all avaible as per your request.

Longer Warranty Period - 18 Months:

Complete After Service Support:

Factory Visit Available:

Strongger commissioning:

we understand that onsite support for commissioning is a crucial activity and hence we provide a skillful team of experienced engineers to ensure that the start-up and commissioning of our system at your plant is smooth.

Our start-up team is capable to manage and reduce unforeseen risks of performance problems and equipment failures. Our team follows standard processes to ensure that the necessary electrical, mechanical and environmental criteria have been met before commissioning.

During special period, our team can provide powerful Remote Commissioning.