- Product Details

- {{item.text}}

Quick Details

-

Power:

-

14kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1000 KG

-

Output product name:

-

potato chips

-

Product Name:

-

french fries potato chips production line

-

Application:

-

vegetable, fruits, meat, chicken, fish

-

function:

-

Produce French Fries Potato Chips, other fried food

-

Finished Products:

-

french fries, potato chips, fried food

-

Material:

-

Food Grade 304 Stainless Steel

-

Advantage:

-

low price, good quality, low running cost

-

Heating method:

-

gas, electricity, diesel

-

After Warranty Service:

-

oversea engineer, video support, spare parts

-

Certification:

-

CE

-

Package:

-

Seaworthy Wooden Case

Quick Details

-

Brand Name:

-

Tinwing

-

Place of Origin:

-

SHN

-

Voltage:

-

220V/380V/400V/415/440V

-

Power:

-

14kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1000 KG

-

Output product name:

-

potato chips

-

Product Name:

-

french fries potato chips production line

-

Application:

-

vegetable, fruits, meat, chicken, fish

-

function:

-

Produce French Fries Potato Chips, other fried food

-

Finished Products:

-

french fries, potato chips, fried food

-

Material:

-

Food Grade 304 Stainless Steel

-

Advantage:

-

low price, good quality, low running cost

-

Heating method:

-

gas, electricity, diesel

-

After Warranty Service:

-

oversea engineer, video support, spare parts

-

Certification:

-

CE

-

Package:

-

Seaworthy Wooden Case

Products Description

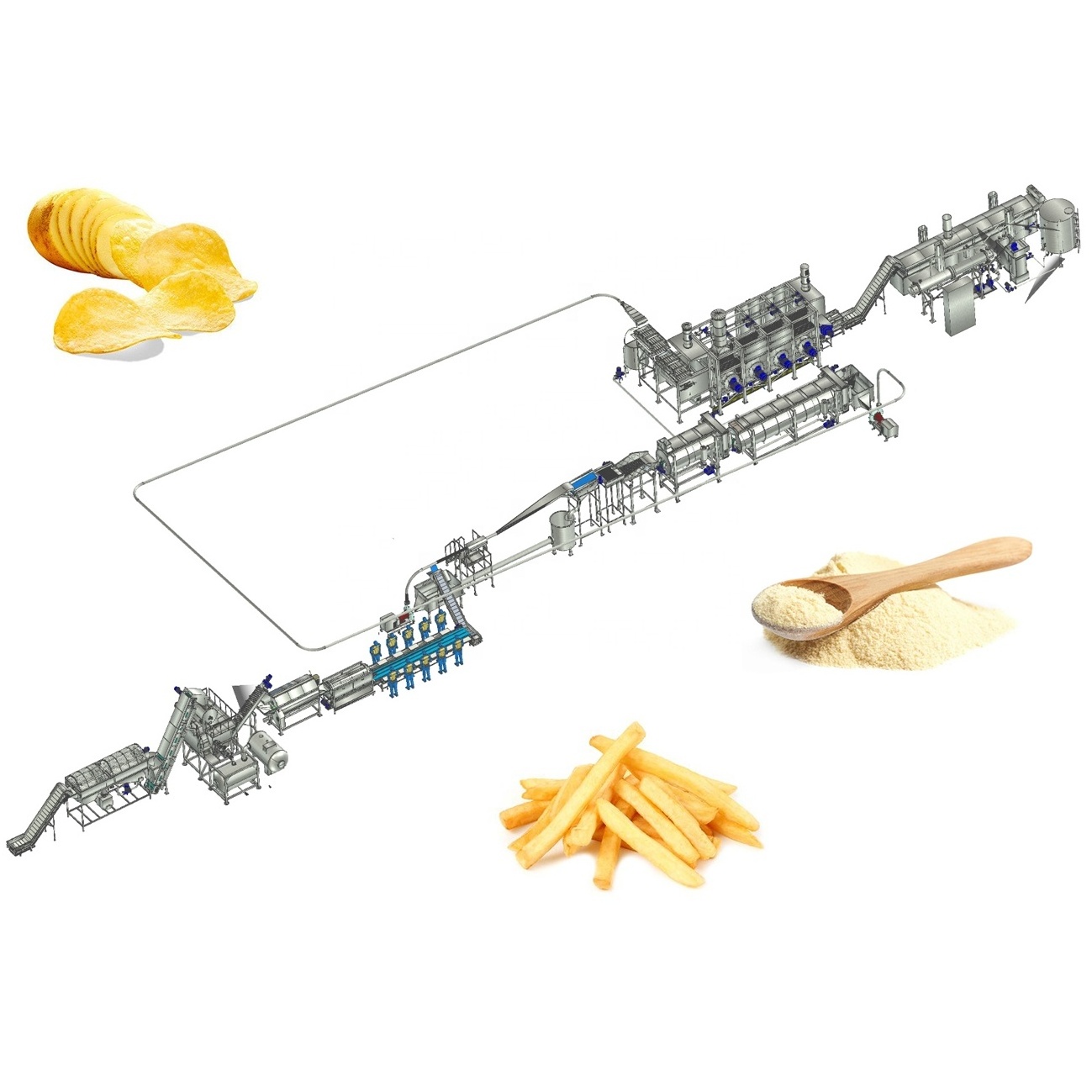

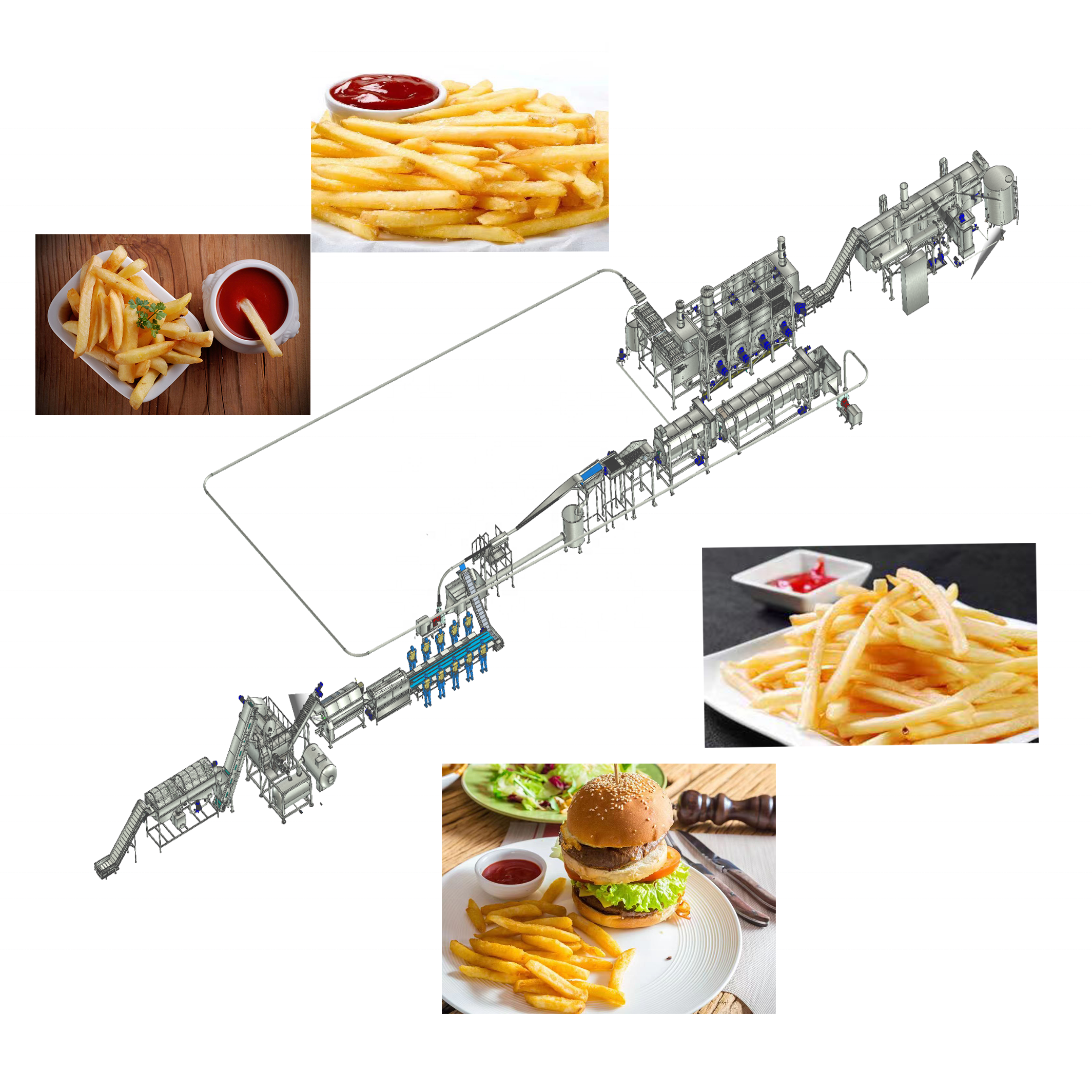

French Fries Production Line

The production line consists of steam peeler, hydro cutter, blancher, drver, fryer, deoiling machine, freezeland packing machine. lt has a maximum automation and achieves continuous and large-scale productionwith a production capacity up to 10 tons / hour.

Product features

Performance and Benefits

1.Meet the needs of large-scale production with a capacity 10tons/hour.

2.Low energy consumption and high efficiency,saving energy significantly.

3.Fully automated design to minimize labor costs.

4.High grade sanitary design for easy cleaning and maintenance.

Technological Process

Process Description .

1.

Loading and conveying

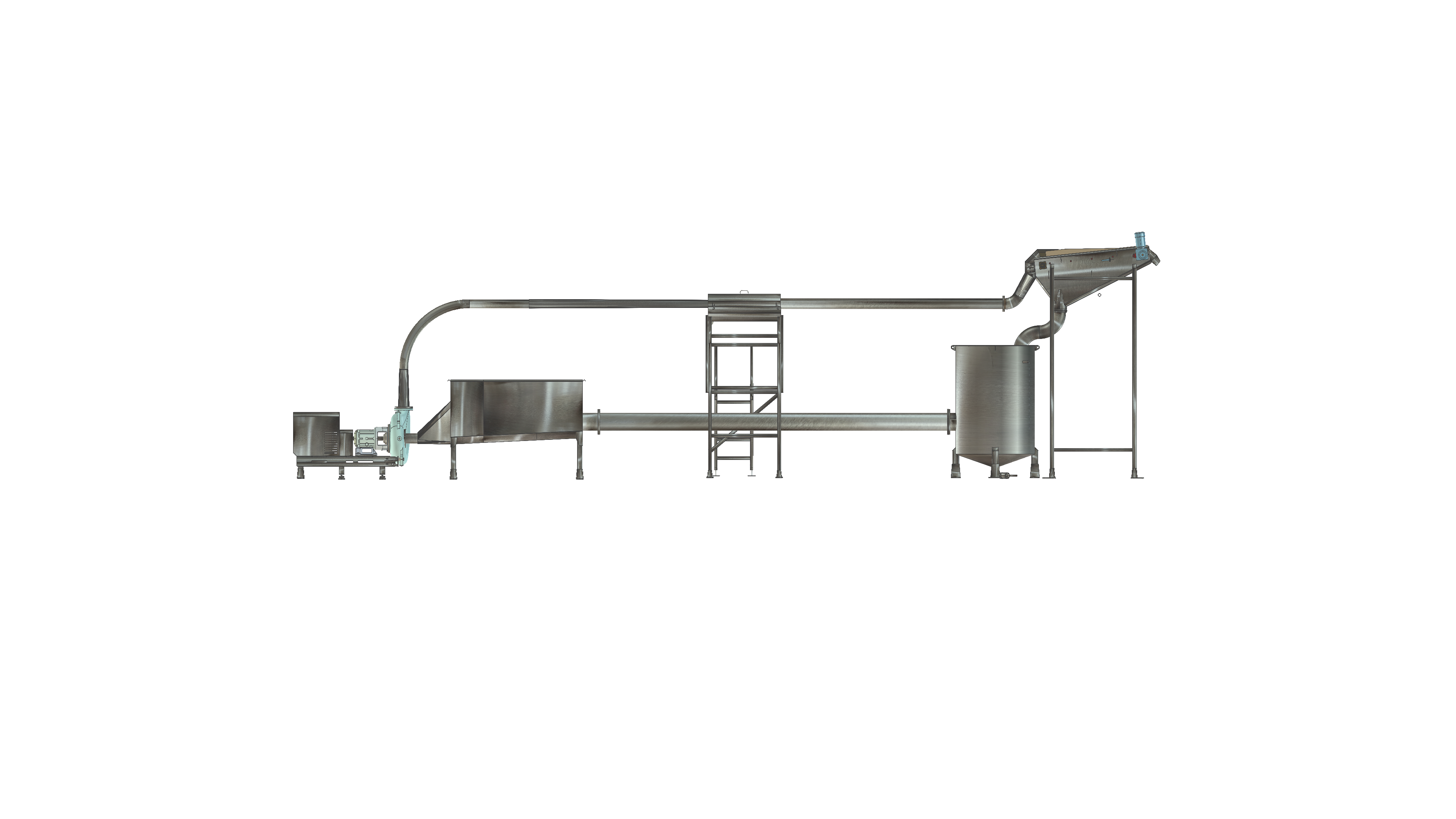

2.Stone cleaning machine: remove stone and soil attached to the surface of the potato.

3.

Steam peelers: Operate steam equipment to quickly remove the skin of potatoes.

4.

Roller cleaning machine: the potato surface residue potato skin and starch clean away.

5.

Manual selection table: pick out the broken potatoes and cut the potatoes that are too large.

6.

Water knife cutting: Cut the potatoes into strips according to the established size standards.

7.

Wafer picker: Screen out the potato strips that do not meet the standard size.

8.

Blanching: Boil the potato strips at the right temperature and remove the starch from the surface of the potato strips.

9.

Color protection: This process keeps the fries from changing color for at least two years.

10.

Remove water to dry: Remove water from the surface of the potato strips.

11.

Fry machine: Fry potato chips, so that the French fries outside crisp inside.

12.

Air cooling 、quick freezing and

package.

Equipment picture

Stone cleaning machine

Steam peeler

machine

Roller cleaning machine

Water knife cutting

Blanching machine

Fry machine

Product packaging

Hot Searches