- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

THD

-

Charator:

-

Energy-saving and High efficiency

-

Lifespan:

-

above 11000hrs

-

Working Pressure:

-

2000-5000pa(0.02-0.05bar)

-

Upper cover:

-

stamped stainless iron

-

Burner plate:

-

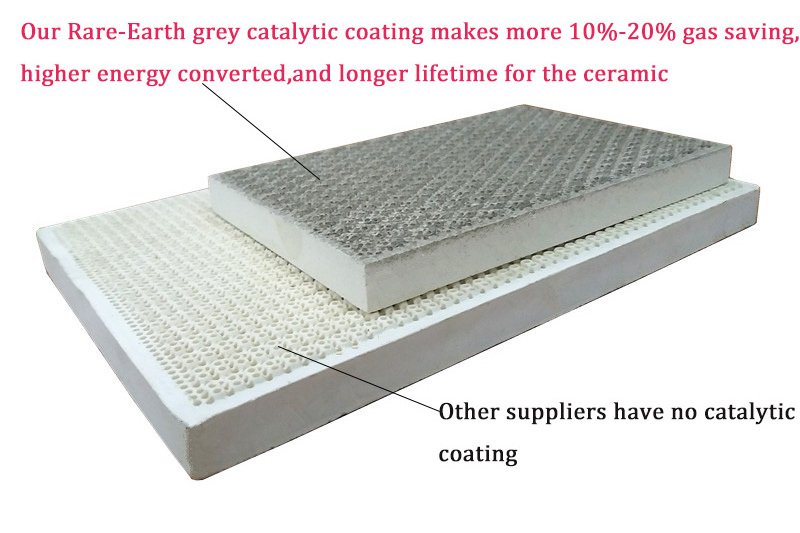

cordierite honeycomb with rare-earth catalyst-coated

-

Advantage:

-

20% gas saving than non-catalyst infrared gas burner

-

Conveyor rate:

-

above 95%

-

Dimension:

-

570*130*175mm

-

Fuel:

-

LPG, natural gas, butane, propane

Quick Details

-

Type:

-

Gas Burner

-

Weight (KG):

-

5.9

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

THD

-

Charator:

-

Energy-saving and High efficiency

-

Lifespan:

-

above 11000hrs

-

Working Pressure:

-

2000-5000pa(0.02-0.05bar)

-

Upper cover:

-

stamped stainless iron

-

Burner plate:

-

cordierite honeycomb with rare-earth catalyst-coated

-

Advantage:

-

20% gas saving than non-catalyst infrared gas burner

-

Conveyor rate:

-

above 95%

-

Dimension:

-

570*130*175mm

-

Fuel:

-

LPG, natural gas, butane, propane

----Now Haodong Technology is the first and only manufacture in China who apply rare- earth catalytic combustion technology in infrared burner&heater.

About us

Established in 2005 ,Chongqing Haodong Technology co.,Ltd is a mannufacturer specialiaed in the research, development and production of infrared catalytic burner.

The inrared burner is based on catalytic combustion patent technique which is advanced in the field and which is developed by Sichuan Chemical Works Ltd. Now thy have been successfully applied in coating,foods drying and baking ,drying process, heating at low and middle temperatures, warming , heat preservaton and so on .

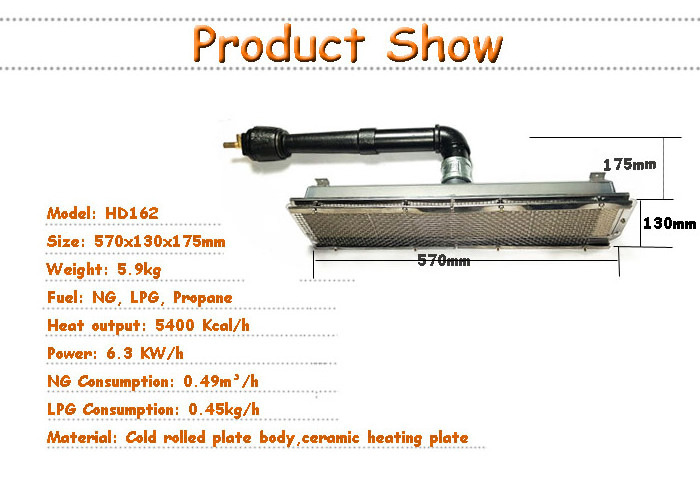

Commercial industrial natural gas burner for furnace oven(HD162)

Material:

1. Shell: Cast Iron

2. Radiant part: cordierite honeycomb plates with black processed rare-earth catalyst coated

3. Nozzle: brass

4. Up cover: stamped stainless iron

Advantages :

Usage of technical parameters

Table 1:The use of technical parameters

|

Items |

Technical parameters |

|

Types |

natural gas (NG),liquefied petroleum gas (LPG) |

|

Light-off temperature |

≥350 |

|

complete combustion temperature |

≤380 |

|

Heat source temperature |

around 850 |

|

Baking temperature range |

30---850 |

|

Wavelength range |

1.9μm--15μm |

|

Furnance pressure natural |

2000pa(NG)/2800pa(LPG) |

Table 2:Comparison table for all kinds of energy consumption

|

Furnace type Parameters |

Electronic

|

Oil furnace |

Coal-fired furnace |

Infrared catalytic heaters |

|

Energy requirement

|

10,000Kcal |

10,000Kcal |

10,000Kcal |

10,000Kcal |

|

Temperature |

180 |

180 |

180 |

180 |

|

Energy consumption |

Electricity(15 kW/h)

|

Electricity (1Kw/h)+ diesel (2Kg) |

Coal (10Kg)

|

LPG(0.9Kg) |

|

Heating time |

20 minutes |

40 minutes |

90 minutes |

5-8 minutes |

Applied Range :

Infrared catalytic gas burner is good choice industrial drying,baking or curing oven,especially in tunnel&converyor oven,saving production&equirpment cost,demand of space is small and easy to control......It martched with auto-igntion,safe controller and keep stable temperature.Now is already widely used industrial drying,especially in metal curing & food baking.......

Color steel plate curing oven outside Color steel plate curing oven inner side

Packing Photos:

Industrial series infrared burners

|

MODEL |

Dimension |

Weight |

GasType |

Heat Output |

Consumption |

||

|

mm |

kg |

KW/h |

Kcal/hr |

NG(m3/h) |

LPG(kg/h) |

||

|

HD61 |

423*80*94 |

3.8 |

NG/LPG |

2.4 |

2030 |

0.18 |

0.18 |

|

HD82 |

219*164*108 |

4.8 |

NG/LPG |

3.1 |

2700 |

0.24 |

0.24 |

|

HD101 |

690*80*115 |

6.9 |

NG/LPG |

3.9 |

3380 |

0.3 |

0.29 |

|

HD162 |

570*130*175 |

5.9 |

NG/LPG |

6.3 |

5400 |

0.49 |

0.47 |

|

HD242 |

840*130*175 |

7.5 |

NG/LPG |

9.4 |

8120 |

0.75 |

0.71 |

|

HD262 |

930*130*175 |

7.8 |

NG/LPG |

10.9 |

9360 |

0.8 |

0.82 |

If any need, please contact us freely,then we will offer the best service

Francis

WhatsApp, WeChat, Mobile: +86 17815004932

QQ: 525379940