1.Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

2.Brake adjustable adopts multipoint braking system.

3.Every stand matched two sets paper car , and they can paper on the both sides at the same time.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

demand to the customs

-

Weight:

-

10000 KG

-

Product name:

-

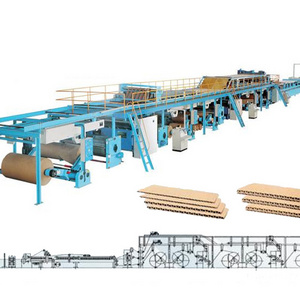

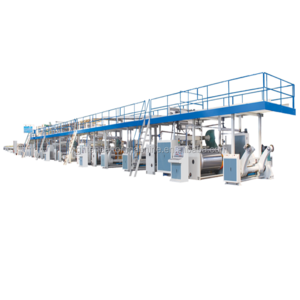

High automatic 3 5 7 corrugated cardboard making line

-

Application:

-

Corrugated Cardboard Production

-

Color:

-

User Defined

-

Packaging Type:

-

Nailless Wooden Box

-

Driven Type:

-

Electric-Pneumatic

-

Type:

-

Corrugated Paperboard Box Making Machine

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

LIHENG

-

Voltage:

-

220v/380v/440v

-

Dimension(L*W*H):

-

demand to the customs

-

Weight:

-

10000 KG

-

Product name:

-

High automatic 3 5 7 corrugated cardboard making line

-

Application:

-

Corrugated Cardboard Production

-

Color:

-

User Defined

-

Packaging Type:

-

Nailless Wooden Box

-

Driven Type:

-

Electric-Pneumatic

-

Type:

-

Corrugated Paperboard Box Making Machine

Products Description

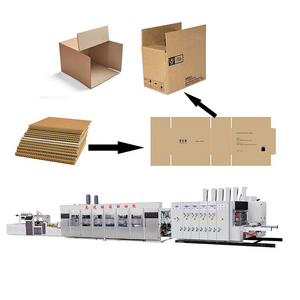

Automatic 3 5 7 corrugated cardboard making line/corrugated machine/carton box manufacturing plant with Hebei Liheng

Details Images

ZJ-V5B hydraulic shaftless mill roll stand part:

Paper trolley,track part:

1.The whole track buried,The main frame of the 14th Channel steel with ¢ 20mm cold drawn welded round,length of track 6000mm.

2.Each paper holder matched two sets paper trolley, and paper on both sides at the same time.pull the roller paper to the right place.

2.Each paper holder matched two sets paper trolley, and paper on both sides at the same time.pull the roller paper to the right place.

RG-900 top(core)paper preheater part:

1.Preheat roller accord the pressure container national standards,and enclose the pressure container certificates and inspection certificate.

2.Each roller surface after grinding precision grinding and dealing with hard chrome plating, Surface friction is small, durable.

3.Electromotion adjustment angle, and angle can rotation adjustment the preheat area in the range of 360°.

2.Each roller surface after grinding precision grinding and dealing with hard chrome plating, Surface friction is small, durable.

3.Electromotion adjustment angle, and angle can rotation adjustment the preheat area in the range of 360°.

SF-360C fingerless type single facer:

1.Adopt suction hood structure,matched high pressure powerful fan. Suction with silence, gas supply and electrical control cabinet to focus on the same operation,away from the host is not less than 1.5m.Operating side closed full cover.

2.The base and wallboard cast iron structure, the thickness of wallboard is 200mm.Independent gear box, universal joint transmission structure.

3.Corrugated roller material adopt 48CrMo alloy steel,diameter of corrugated roller main roller ¢ 360mm,Quenched, CNC grinder grinding, IF quenching, surface finish,surface tungsten carbide dealing, surface hardness above HV1200 degree.Bearing of corrugated roller and pressure roller key parts adopt Timken bearings produce heat.

4.Pressure roller364mm,surface grinding and dealing with chrome,cylinder control moves up and down,No. 45 carbon steel material,quenching (with cushioning devices).

5.Glue wallboard adopt skateboard-type structure, pneumatic control glue to glue back, diameter of glue roller is 242mm, engraved polished surface after a 25-line pit style textured machined chrome plated,After scraping the roller surface polished hard chrome plated.

6.Glue part can remove overall, exchange glue roller quickly and convenient.Electric compartment plastic, electric adjustment amount of glue Digital.

7.Material of corrugated and pressure is provided by zhongyuan tegang,corrugated roller side 0.15mmon high, pressure roller side 0.075mm high.Add limited device.

8.Corrugated roller and pressure roller adopt air spring pressure device, and working stable .

9.Preheat roller adopt seamless steel pipe produced by tiangang¢ 400mm,All metal hose connection.

2.The base and wallboard cast iron structure, the thickness of wallboard is 200mm.Independent gear box, universal joint transmission structure.

3.Corrugated roller material adopt 48CrMo alloy steel,diameter of corrugated roller main roller ¢ 360mm,Quenched, CNC grinder grinding, IF quenching, surface finish,surface tungsten carbide dealing, surface hardness above HV1200 degree.Bearing of corrugated roller and pressure roller key parts adopt Timken bearings produce heat.

4.Pressure roller364mm,surface grinding and dealing with chrome,cylinder control moves up and down,No. 45 carbon steel material,quenching (with cushioning devices).

5.Glue wallboard adopt skateboard-type structure, pneumatic control glue to glue back, diameter of glue roller is 242mm, engraved polished surface after a 25-line pit style textured machined chrome plated,After scraping the roller surface polished hard chrome plated.

6.Glue part can remove overall, exchange glue roller quickly and convenient.Electric compartment plastic, electric adjustment amount of glue Digital.

7.Material of corrugated and pressure is provided by zhongyuan tegang,corrugated roller side 0.15mmon high, pressure roller side 0.075mm high.Add limited device.

8.Corrugated roller and pressure roller adopt air spring pressure device, and working stable .

9.Preheat roller adopt seamless steel pipe produced by tiangang¢ 400mm,All metal hose connection.

ZDF conveyor bridge part:

1.Independent frequency motor lifting mechanism, PVC conveyor belt, a single watt of cardboard into a wavy rule stable.

2.All roller surface after grinding hard chrome plated.

3.Vacuum adsorption tension control,5-inch suction tube,add regulator valve,air volumestepless adjustable air volume.

4.Electric corrective devices II sets,correction baffle double guide column positioning, Screw Driver,positioning fast and accurate , smooth running.

2.All roller surface after grinding hard chrome plated.

3.Vacuum adsorption tension control,5-inch suction tube,add regulator valve,air volumestepless adjustable air volume.

4.Electric corrective devices II sets,correction baffle double guide column positioning, Screw Driver,positioning fast and accurate , smooth running.

SM-E1 type double facer part:

1.Heating plate surface by grinding treatment,hot plate width600mm,a total of 18 pieces heating plate,cooling setting length is 5 meters.Heating plate with container board production, in accordance with the national standard of pressure container,enclosed the

pressure container certificate and inspection certificate.

2.Upper belt left adopt pneumatic automatic correction .

3.Heating plate heat transfer pipe temperature control sub-five-segment, with a temperature display.

4.Upper cotton belt with double cylinder S cotton belt tensioning device.

5.Lower belt adopt pneumatic tensioning.

6.Drive roller coated with attached wear-resistant rubber ,showed a middle-high structure, ensure cardboard output smooth.

7.Electric components used internationally renowned brands, device stable and reliable operation.

8.Main drive motor is variable frequency motor speed, low-speed torque, wide speed range, reliable, and easy maintenance.

9.Hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam.

10.The main backbone of high-strength GB profiles, solid structure, beautiful appearance, suitable for high speed working.

pressure container certificate and inspection certificate.

2.Upper belt left adopt pneumatic automatic correction .

3.Heating plate heat transfer pipe temperature control sub-five-segment, with a temperature display.

4.Upper cotton belt with double cylinder S cotton belt tensioning device.

5.Lower belt adopt pneumatic tensioning.

6.Drive roller coated with attached wear-resistant rubber ,showed a middle-high structure, ensure cardboard output smooth.

7.Electric components used internationally renowned brands, device stable and reliable operation.

8.Main drive motor is variable frequency motor speed, low-speed torque, wide speed range, reliable, and easy maintenance.

9.Hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam.

10.The main backbone of high-strength GB profiles, solid structure, beautiful appearance, suitable for high speed working.

NCBD thin blade slitter scorer part:

1.Synchronous servo motor control row of knives, cable. Automatic reset. Precise dimensions.change order time 3-8 seconds,the two machines can be achieved with no slow down immediately for a single memory of 999 order,non-stop automatic change order or manual change order can be realized.

2. Schneider M258PLC control system, using CANopen line system, with order management capabilities, with the dryer speed synchronous signal input.

3.HMI with 10.4-inch color touch screen, storage 999 orders, change orders automatically or manually for a single, fault alarm.

4.Three kinds of pressure line forms:Convex against the concave(three layers line),convex against the concave(five layers line),Convex against Flat,Three kinds of electric pressure line forms can be converted.Crimping round shades by computer control,linear, and easy to bend.

5.Using thin tungsten alloy steel knife,sharp blade,long life of more than 8 million meters.

6.knife sharpener for computer control,automatic or manual knife sharpener,Cutting edge sharpening can be divided,improve productivity Efficiency.

7.Imported synchronous drive system, precision accurate, long life, low noise operation.

2. Schneider M258PLC control system, using CANopen line system, with order management capabilities, with the dryer speed synchronous signal input.

3.HMI with 10.4-inch color touch screen, storage 999 orders, change orders automatically or manually for a single, fault alarm.

4.Three kinds of pressure line forms:Convex against the concave(three layers line),convex against the concave(five layers line),Convex against Flat,Three kinds of electric pressure line forms can be converted.Crimping round shades by computer control,linear, and easy to bend.

5.Using thin tungsten alloy steel knife,sharp blade,long life of more than 8 million meters.

6.knife sharpener for computer control,automatic or manual knife sharpener,Cutting edge sharpening can be divided,improve productivity Efficiency.

7.Imported synchronous drive system, precision accurate, long life, low noise operation.

NC cutter helical knives part:

1.It can store 180 units orders,replace the cutter specifications quickly and accurately, changing orders without stop,And enables networked computers to facilitate production management.

2.Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy.

3.Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life.

4.Around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage.

5.Precision adjustable no gap gear to ensure precise blade engagement, running balance.

6.Knife roller: fine quality forged steel material, the balanced, with good stability.

7.Host base and wall of gray cast iron, rigidity, vibration resistance.

8.Germany Bryant servo motor drive controller,Taiwan Eview yield 10.4 inches color touch screen display, the project at a glance.

9.Cutting length: 500mm-9000mm, cutting precision: ± 1mm (when steady speed )

2.Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy.

3.Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life.

4.Around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage.

5.Precision adjustable no gap gear to ensure precise blade engagement, running balance.

6.Knife roller: fine quality forged steel material, the balanced, with good stability.

7.Host base and wall of gray cast iron, rigidity, vibration resistance.

8.Germany Bryant servo motor drive controller,Taiwan Eview yield 10.4 inches color touch screen display, the project at a glance.

9.Cutting length: 500mm-9000mm, cutting precision: ± 1mm (when steady speed )

Automatic gantry stacking machine part:

1.Gantry stacking.Changing single time is 5seconds,automatic counting, automatic cross out automatically for a single.

2.Synchronized with the production management system , order mangement , Centralized management,do not slow down automatically for a single.

3.Production management for a single waste less than 700mm.

4.Crawler stacking platform,AC servo control movements,Stacking smooth, neat;

5.When stacking reaches a set number of automatic frequency control smooth laterally out of paper;

6.Tailgate AC servo control positioning for a single automatic, rapid, precise adjustment;

7.Tailgate automatically shift for small orders stacking;

8.Delivery side of the standard electric transport planes, and duplex trolley.

9.Independent sealed control cabinets, electrical equipment operating under clean environment;

10.Color touch-screen display for easy on-site operation.

11.Fully automatic operation control, improve efficiency and save manpower, reduce labor intensity

2.Synchronized with the production management system , order mangement , Centralized management,do not slow down automatically for a single.

3.Production management for a single waste less than 700mm.

4.Crawler stacking platform,AC servo control movements,Stacking smooth, neat;

5.When stacking reaches a set number of automatic frequency control smooth laterally out of paper;

6.Tailgate AC servo control positioning for a single automatic, rapid, precise adjustment;

7.Tailgate automatically shift for small orders stacking;

8.Delivery side of the standard electric transport planes, and duplex trolley.

9.Independent sealed control cabinets, electrical equipment operating under clean environment;

10.Color touch-screen display for easy on-site operation.

11.Fully automatic operation control, improve efficiency and save manpower, reduce labor intensity

Product packaging

Plastic film packaging machines. With wire and the machine is fixed to the container. When the container operations and surface bumps, the machine will not shake.

Hot Searches