- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SIGO

-

Dimension(L*W*H):

-

102*61*60 CM

-

Weight:

-

100 KG

-

Product name:

-

650A Double Sides Heavy Duty High Quality Laminator Laminating Machine

-

Max. Laminating Width:

-

650mm

-

Max. Laminating Thcikness:

-

6mm

-

Laminating Speed:

-

0.6-2.5m/min

-

Laminating Temperature:

-

0-180 Celsius degree

-

Membrane Core Size:

-

1",2",3"

-

Roller Material:

-

Silicon

-

Laminate Type:

-

Single+Double Sides

-

LCD Control:

-

Yes

-

Sample:

-

Acceptalbe

Quick Details

-

Packaging Type:

-

Film, Bookcover, Picuter, Photo,etc

-

Packaging Material:

-

Paper, Plastic

-

Driven Type:

-

Electric

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SIGO

-

Dimension(L*W*H):

-

102*61*60 CM

-

Weight:

-

100 KG

-

Product name:

-

650A Double Sides Heavy Duty High Quality Laminator Laminating Machine

-

Max. Laminating Width:

-

650mm

-

Max. Laminating Thcikness:

-

6mm

-

Laminating Speed:

-

0.6-2.5m/min

-

Laminating Temperature:

-

0-180 Celsius degree

-

Membrane Core Size:

-

1",2",3"

-

Roller Material:

-

Silicon

-

Laminate Type:

-

Single+Double Sides

-

LCD Control:

-

Yes

-

Sample:

-

Acceptalbe

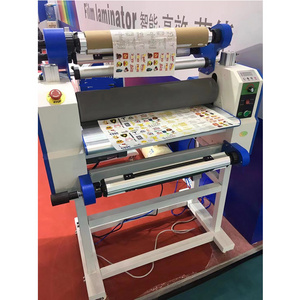

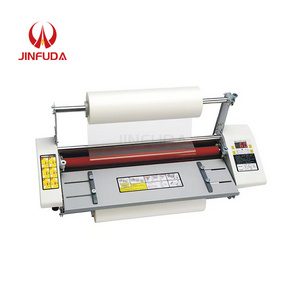

650A Double Sides Heavy Duty High Quality Laminator Laminating Machine Price

Hot and Cold 650mm Roller Lamintor Laminating Machine Detail Spec:

Product Introduction

Heated roll laminator uses heated rollers to melt glue extruded onto lamination film. This film is in turn applied to a substrate such as paper or card using pressure rollers. The primary purpose of laminating with such a machine is to embellish or protect printed documents or images. Heated roll laminators can vary in size from office based pouch laminators to industrial sized machines. Such industrial machines are primarily used for high quantity/quality output by printers or print finishers.

Whether small office or industrial machines their primary function is to embellish or protect printed works. Such laminators are used to apply varying thicknesses of lamination film onto substrates such as paper or fabrics. The main advantage to the use of heated roll laminators is that of speed. Heated laminators use heated rollers or heated shoes to melt the glue which is applied to lamination film. The process of heating the glue prior to applying the film to a substrate allows for a faster application of the film. The laminates and adhesives used are generally cheaper to manufacture than cold roll laminates, often as much as half the cost depending on the comparison made. As the materials are non-adhesive until exposed to heat, they are much easier to handle. The glue is solid at room temperature, so lamination of this type is less likely to shift or warp after its application than pressure activated laminates, which rely on a highly viscous, adhesive fluid.

| Max. lamination width: | 630mm | |

| Max. lamination speed: | 1600mm/min | |

| Max. lamination temperture: | 140C | |

| Max. clearance between top bottom rollers: | 5mm | |

| Electric: | AC220,110V /50,60HZ | |

| Power: | 1300w | |

| Heating roller dia: | 54mm | |

| Pull roller dia: | 45mm | |

| size: | 910*520*310 | |

| weight: | 38kg | |

| Diameter of the core: | 1,1.5,3 inch | |

A1 A2 A3 A4 A5 A6 Size 650mm Roller Laminator Package & Shipping to Ningbo Port