- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

3600/4500/5000/7200/14400/15000mm

-

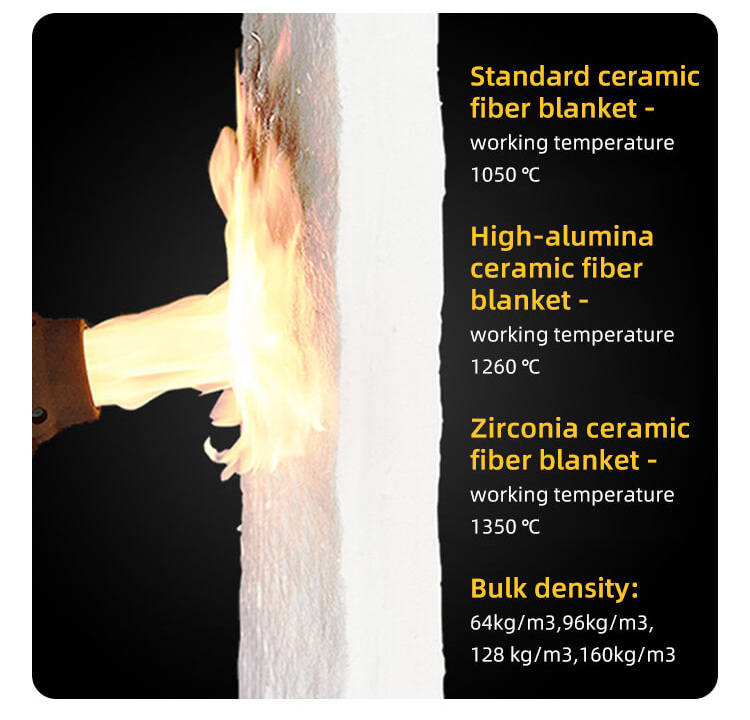

Working Temperature:

-

1100C/1260C/1360C/1430C, 1000-1350℃

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

24h -3

-

Thermal Conductivity:

-

0.16(800 )

-

Model Number:

-

1600 Ceramic Fiber Blanket

-

Brand Name:

-

RONGSHENG

-

Place of Origin:

-

Henan, China

-

Product name:

-

refractory ceramic fiber blanket

-

Organic content(%):

-

Ceramic Fiber

-

Keyword:

-

aluminum silicate blanket with aluminum foil

-

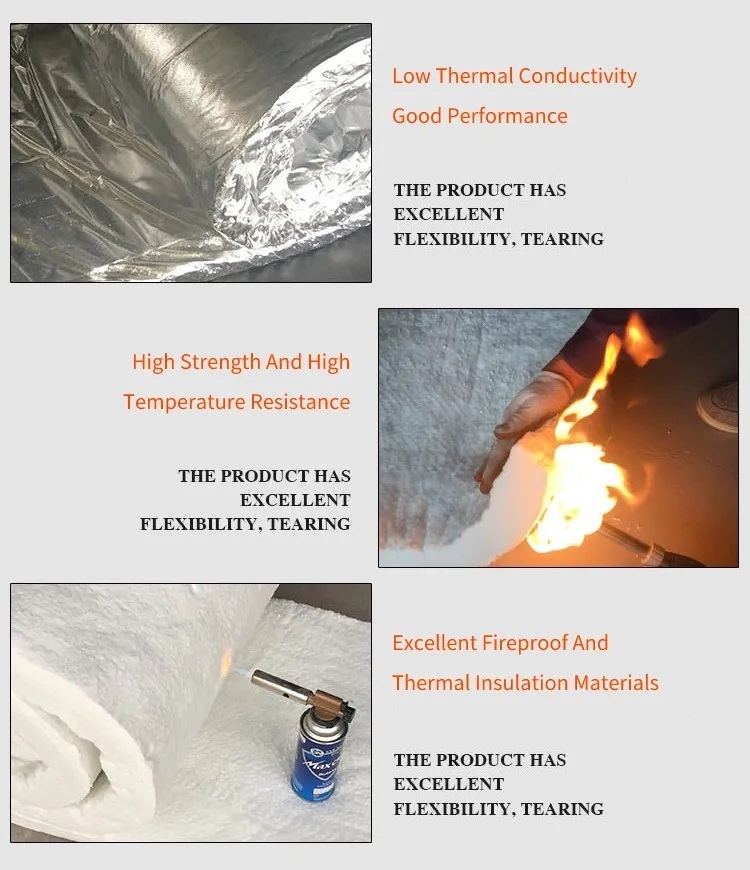

Advantage:

-

Low thermal conductivity

-

Feature:

-

Heat Resistant Insulation

-

Package:

-

Plastic Bag Inside, Braided Bag Outside

-

Certificate:

-

CE ISO

Quick Details

-

Thickness:

-

10-50mm, 10-50mm or Customer Requests

-

Width:

-

610/1220mm

-

Chemical Composition:

-

AL2O3+SIO2+Zro2

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

3600/4500/5000/7200/14400/15000mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C, 1000-1350℃

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

24h -3

-

Thermal Conductivity:

-

0.16(800 )

-

Model Number:

-

1600 Ceramic Fiber Blanket

-

Brand Name:

-

RONGSHENG

-

Place of Origin:

-

Henan, China

-

Product name:

-

refractory ceramic fiber blanket

-

Organic content(%):

-

Ceramic Fiber

-

Keyword:

-

aluminum silicate blanket with aluminum foil

-

Advantage:

-

Low thermal conductivity

-

Feature:

-

Heat Resistant Insulation

-

Package:

-

Plastic Bag Inside, Braided Bag Outside

-

Certificate:

-

CE ISO

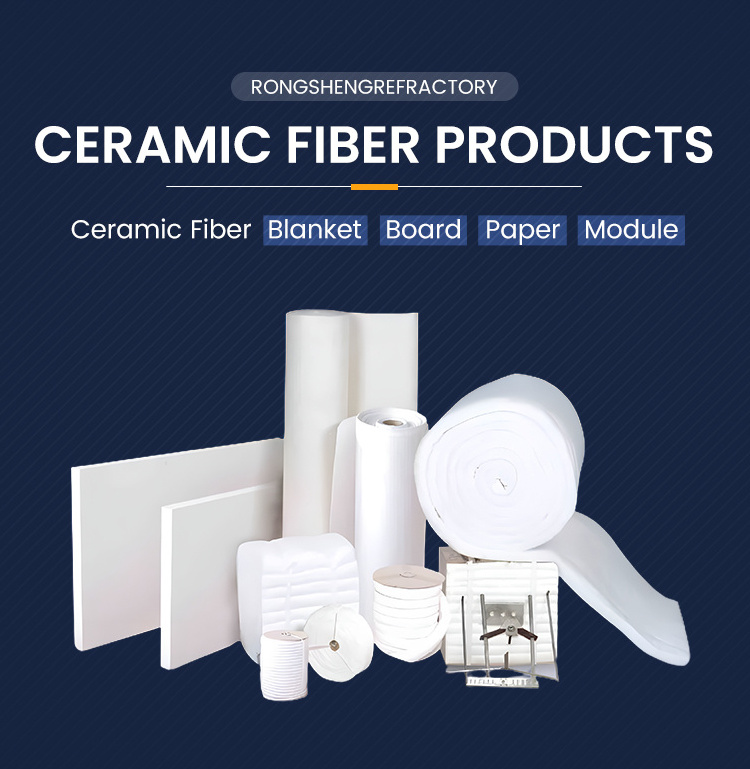

High temperature 1600 refractory ceramic fiber blanket 160kg/m3 aluminum silicate fiber blanket with aluminum foil

Ceramic Fiber Blanket Introduce

[

FIREPROOF INSULATION

] kaowool fireproof ceramic fiber insulation blanket is rated to 2400F so that it can maintain complete shape and size after the fire burns. Our ceramic fiber blanket brings you excellent thermal shock resistance and low heat storage capacity.

[

HIGH QUALITY & DURABILITY

] The high temperature insulation blanket is 128 Kg/ M3 density, contains no binders and is completely inorganic. These rockwool insulation have high tensile strength for longer life and durability.

[

EASY TO USE

]Our ceramic fiber blanket thickness is even, flexible, and easy to install.

[

WIDELY APPLICATIONS

] Perfect ceramic fiber insulation for furnace, kiln, dishwasher insulation blanket, oven insulation, wood stove, welding, foundry, refractory, glass blowing, and jewelry making.

[

100% SATISFACTION GUARANTEE

] Order with confidence! Every kaowool fireproof ceramic fiber insulation blanket has been tested strictly to ensure higher quality.

We are committed to providing the High-quality ceramic fiber blanket to all our customers forever!

Our products are thermally efficient and lightweight making them an ideal choice in your insulation needs.

Features of Ceramic Fiber Insulation Blanket

1. High heat oven insulation blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket.

2. High heat oven insulation blanket contains no organic binders which guarantee the stability and constructability of the ceramic fiber blanket at both high temperature and low temperature.

3.Temperature: Rated to 2400℉.Our products have high heat insulation efficiency and light weight, which are the ideal choice for your heat insulation needs.

4.Ultra-high density: 128 Kg/ M3, fine and soft texture, make our insulation blanket your best choice!

Application of Ceramic Fiber Blanket

| Industry | Applications |

| Ceramic industry |

Kiln car insulation and seals,

Continuous and batch kilns |

| Steel industry |

Heat treating and annealing furnaces, Furnace door linings and seals,

Soaking pit covers and seals, Furnace hot face repairs, Reheating furnace and ladle covers, |

| Refining and petrochemical industry |

Reformer and pyrolysis lining,

Tube seals,gaskets and expansion joints, High temperature pipe,duct and turbine insulation Crude oil heater linings |

| Power generation industry |

Boiler insulation,Boiler doors,Reusable turbine covers,

Expansion seals/pipe coverings |

| Other |

Insulation of commercial dryers and ovens

Veneer over existing refractory Stress relieving insulation Glass furnace crown protection Fire protection |

| Type | COM | ST | HP | HA | Zir-Alu | HZ | |

| Classified Temp |

1100℃

(2012℉) |

1260℃

(2300℉) |

1260℃

(2300℉) |

1360℃

(2480℉) |

1400℃

(2550℉) |

1430℃

(2606℉) |

|

| Working Temp |

<1000 ℃

(1832℉) |

1050℃

(1922℉) |

1100℃

(2012℉) |

1200℃

(2192℉) |

1200℃

(2192℉) |

1350℃

(2462℉) |

|

| Color | white | white | white | white | white | white | |

| Density(kg/m3) |

96/128

(6/8 lb/ft3) |

96/128

(6/8 lb/ft3) |

96/128

(6/8 lb/ft3) |

128/160

(8/10 lb/ft3) |

128/160

(8/10 lb/ft3) |

128/160

(8/10 lb/ft3) |

|

| Linear Shrinkage (%)(24 hrs,density 128 kg/m³) |

-4

(1000℃/ 2012℉) |

-3

(1000℃/1832℉) |

-3

(1100℃/2012℉) |

-3

(1250℃/2282℉) |

-3

2192℉) |

-3

2462℉) |

|

|

Thermal

conductivity (W/M.K) Density 128kg/m³ ( 8 lb/ft3) |

0.09

1472℉) |

0.09(

1472℉) |

0.09

1832℉) |

0.12

1832℉) |

0.132

1832℉) |

0.16

1832℉ |

|

|

Tensile Strength

(Mpa) (Density 128kg/m³) |

0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | |

|

Chemica (%)l |

Al2O3 | 44 | 46 | 47-49 | 52-55 | 45-46 | 39-40 |

|

Al2O3+

SiO2 |

96 | 97 | 99 | 99 | - | - | |

|

Al2O3+

SiO2+ ZrO2 |

- | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 5-7 | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | 0.2 | |

|

Na2O+

K2O |

≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Size(mm) |

7200/3600*610/1220/10-50mm or customized as your specification

24′/12′ * 24"/48" * 0.4"/2" |

||||||