- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINBEI

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

Variable

-

Power (kW):

-

22

-

Weight (T):

-

6.5

-

Core Components:

-

blades, shaft

-

Marketing Type:

-

New Product 2022

Quick Details

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

1000 - 1600 kg/h

-

Brand Name:

-

XINBEI

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

Variable

-

Power (kW):

-

22

-

Weight (T):

-

6.5

-

Core Components:

-

blades, shaft

-

Marketing Type:

-

New Product 2022

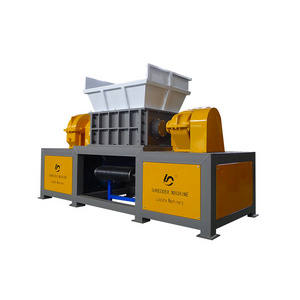

Product Description

Features:

1.Shaft is specially processed by machinery center, whole body without a welding spot. Shear type moving knife adopts separated connection method, bolted into shaft with screws. Reduce wearing cost and future maintenance time.

2.Transmission system is composed of motor, reducer and coupling, tightly connected. While driving and driven shaft is linked by gears. Ensure high efficiency, low rotating rate, high torque and low noise.

3.Electrical system adopts PLC program,features start, stop, reverse functions along with automatic overload return mechanism to prevent damage to working parts. Lower labor intensity and longer machine service life.

Usage:

1.Plastic barrel, plastic bottle

2.Metal drum,metal cans

3.Tire, bumper, roadblock, battery

4.Washer, fridge and other waste home appliances.

5.Carcass,domestic garbage,paper-mill wastes

|

Shredder model

|

XB-F600

|

XB-F800

|

XB-F1000

|

XB-F1200

|

XB-F1600

|

|

Shaft diameter

|

320mm×4

|

320mm×4

|

360mm×4

|

360mm×4

|

430mm×4

|

|

Moving knife qty.

|

24pcs

|

32 pcs

|

40 pcs

|

48 pcs

|

64 pcs

|

|

Maximum capacity

|

500kg/h

|

800kg/h

|

1000kg/h

|

1300kg/h

|

1600kg/h

|

|

Motor power

|

15KW×2

|

18.5KW×2

|

22KW×2

|

30KW×2

|

45KW×2

|

|

Chamber size

|

600Lx1030W

|

800Lx1030W

|

1000Lx1080W

|

1200Lx1080W

|

1600Lx1260W

|

|

Host weight

|

3500kg

|

5000kg

|

6500kg

|

8000kg

|

9000kg

|

|

Dimensions

|

2960L×1110W×2300H

|

3160L×1130W×2400H

|

3360L×1170W×2500H

|

3560L×1200W×2550H

|

3760L×1360W×2600H

|

More Products

Company View

Exhibition

Certifications

Partner

Packaging&Shipping

FAQ

A) The difference between shredder and crusher machine - how to choose the right equipment?

Shredder and crusher machine,they are have a big difference.It's the "tear" and "break" two words to define the main differences.

1) First of all, shredding machine and crusher for the size of the material is different, shredding machine is to tear the

material into irregular 20mm - 200mm or even larger size block. The crusher is to further break these massive materials into small pieces below 20mm, so as to achieve further processing conditions, such as granulation after cleaning.

2) Secondly, the principle is different, The speed between the two is also different. Shredding machine is mainly rely on low

speed, large torque, by different of the speed between the shafts to tear, cut, grind of materials. But crusher is with high

inertia impact and sharp of the rotating moving knife and fixed on both rotating, to shear way and chop up the materials. 3)Finally, the material of shredding is mostly large size and strong, the material of crusher is normal and small size. From the point of view of use, shredding has more safety, less manual operation, low noise. Crushing is high noise, needs more manual operation and maintenance.

E) About the blades of shredder, and how to choose the correct blades?

Our blades must be carried out the technological process and standards to execute, otherwise will affect the service life of its, and processing as follows:

Shredder and crusher machine,they are have a big difference.It's the "tear" and "break" two words to define the main differences.

1) First of all, shredding machine and crusher for the size of the material is different, shredding machine is to tear the

material into irregular 20mm - 200mm or even larger size block. The crusher is to further break these massive materials into small pieces below 20mm, so as to achieve further processing conditions, such as granulation after cleaning.

2) Secondly, the principle is different, The speed between the two is also different. Shredding machine is mainly rely on low

speed, large torque, by different of the speed between the shafts to tear, cut, grind of materials. But crusher is with high

inertia impact and sharp of the rotating moving knife and fixed on both rotating, to shear way and chop up the materials. 3)Finally, the material of shredding is mostly large size and strong, the material of crusher is normal and small size. From the point of view of use, shredding has more safety, less manual operation, low noise. Crushing is high noise, needs more manual operation and maintenance.

B) How to choose shredding machine? Shredding machine of classification.

Three kinds of shredding machine

1) For the number of shafts have three models: single shaft shredder (1 shaft), double shaft shredder (2 shafts), four shaft shredder (4 shafts).

2) For the driving mode have two models: motor driving, and hydraulic motor driving. 3) For the material types, it's a little more complex, the XINBEI Machinery will be divided into the following kinds of, (1) Plastic hard shredder (such as: plastic pipes, plates, garbage cans, plastic baskets and other surface hard plastic), (2) Plastic soft shredder (such as: Film, tons of bags, woven bags, packaging bags and other soft plastic (3) metal shredder (the machine can tear various metals), (4) tree and straw shredder (can broken straw and tree) . How should we choose shredding machine? When you want a shredder, you should understand the purpose of use, whether to reduce the amount of processing or coarse crushing processing, and you should clear the kind of material, then find a good manufacturer like XINBEI to help you get a suitable machine model which can match your requirements.

C) The price of the junked tire shredder

The price of junked tire shredder main depend on

1, The type of machine;

2. Capacity;

3.Equipment quality;

D) How much is a double shafts shredder?

There are many factors that determine the price of the shredding machine. E.g. The material, blade, shaft, motor, technology, function and specification and capacity etc. so the price space from tens of thousands to hundreds of thousands USD. We need according to the situation of our production to select and buy the best machine.

(1) Material selection;

(2) blanking forging;

(3) tempering;

(4) primary processing;

(5) Heat treatment;

(6) Plane grinding;

(7) wire cutting;

(8) Accurate grinding.

Hot Searches