- Product Details

- {{item.text}}

Quick Details

-

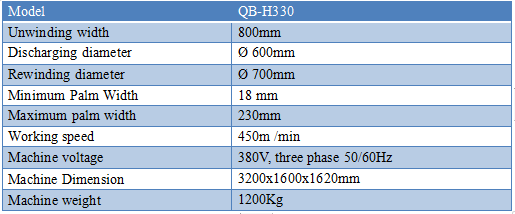

Voltage:

-

380V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

3200x1600x1620mm

-

Weight:

-

1200 KG, 1300

-

Function:

-

Forming - Rolling - Labeling - Stacking

-

Product name:

-

Shrink sleeve label making

-

Label material:

-

PET PVC PE

-

Suitable for:

-

shrink sleeve labeling machine

-

Speed:

-

450m/min

-

Glue type:

-

liquid label

-

After-sales Service Provided:

-

Online Support\Video Technical Support

-

Usage:

-

making roller label

Quick Details

-

Application:

-

Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

-

Packaging Type:

-

case

-

Packaging Material:

-

Wood

-

Voltage:

-

380V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

3200x1600x1620mm

-

Weight:

-

1200 KG, 1300

-

Function:

-

Forming - Rolling - Labeling - Stacking

-

Product name:

-

Shrink sleeve label making

-

Label material:

-

PET PVC PE

-

Suitable for:

-

shrink sleeve labeling machine

-

Speed:

-

450m/min

-

Glue type:

-

liquid label

-

After-sales Service Provided:

-

Online Support\Video Technical Support

-

Usage:

-

making roller label

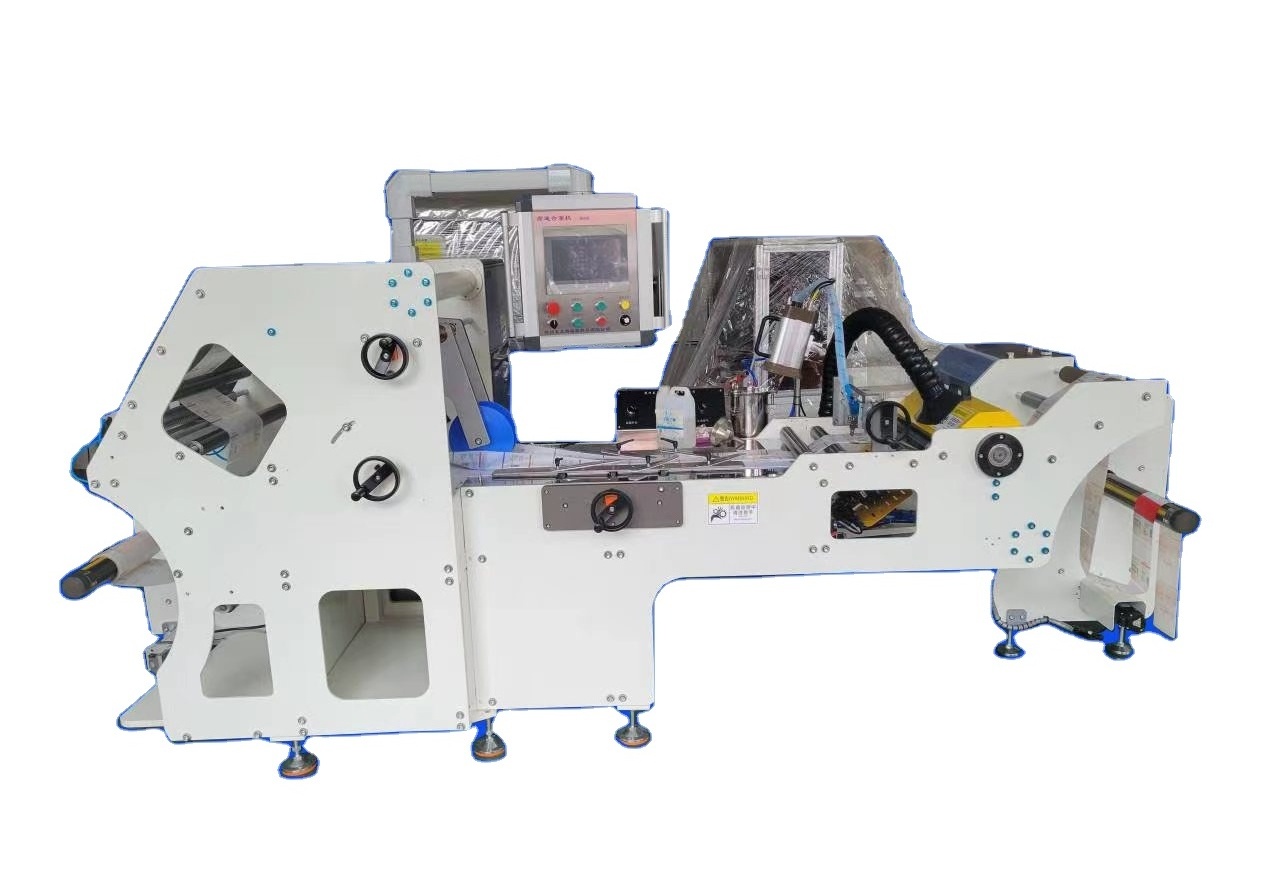

Product Overview

Shrink Sleeve Label Seaming Machine

Features:

(1)

The host structure of the equipment adopts all fine steel structure

(2) The spindle drive stick is made of seamless steel pipe, which has been processed by quenching and tempering, surface hardening, plating and dynamic balancing.

(3)

The feeding guide rollers are metal rollers (aluminum alloy) and rubber rollers ( Nitronitrile rubber );

(4)

The transmission mode of the main machine and receiving material is synchronous wheel and synchronous belt transmission;

(5)

Adopt double traction pulling material, with the brand tension sensor;

(6)

Closed-loop feeding system is adopted for feeding with palms together;

(7)

The whole machine adopts 6 servo motors to coordinate work.

PRODUCT SPECIFICATIONS

Briefly Description

1) Model type: You don't have to change the mold when you change the width of the label

2) 6 servo motors control

4) Air release holes making function (Two)

5)Perforation lines (easy tearing lines) making function (Double lines)

5) Oscillation rewinding device is controlled by a servo motor

7) It can remember more than 100 groups of data which help you control the machine easier

2) 6 servo motors control

4) Air release holes making function (Two)

5)Perforation lines (easy tearing lines) making function (Double lines)

5) Oscillation rewinding device is controlled by a servo motor

7) It can remember more than 100 groups of data which help you control the machine easier

DETAILS IMAGES

FAQ

1.Question: What's your main products?

Reply: we produce Sleeve labeling machine, Adhesive sticker labeling machine, OPP Hot melt glue labeling machine etc.

2.Question: Are you factory?

Reply: Yes, Our factory located in No.5 huasheng east road, zhoushi town, kushan city, Jiangsu province, China.

Shanghai Office address: 777 Fuhai Road, Jiading Industrial area, Jiading District, Shanghai, China.

3.Question: If I have special needs about design about the bottle label and machine,can you do that for me?

Reply: We have the professional designers, can design under your needs, based on the bottle/label sample, we also can supply plant engineering service for you;

4.Question:How about your after-sale service?

Reply: we have professional technical department to ensure the machine functioning well, both hardware and software technology;

5.Question: How long about the delivery time?

Reply: When we get your advance deposit, and your bottle&label samples, it about 20 days.

Reply: we produce Sleeve labeling machine, Adhesive sticker labeling machine, OPP Hot melt glue labeling machine etc.

2.Question: Are you factory?

Reply: Yes, Our factory located in No.5 huasheng east road, zhoushi town, kushan city, Jiangsu province, China.

Shanghai Office address: 777 Fuhai Road, Jiading Industrial area, Jiading District, Shanghai, China.

3.Question: If I have special needs about design about the bottle label and machine,can you do that for me?

Reply: We have the professional designers, can design under your needs, based on the bottle/label sample, we also can supply plant engineering service for you;

4.Question:How about your after-sale service?

Reply: we have professional technical department to ensure the machine functioning well, both hardware and software technology;

5.Question: How long about the delivery time?

Reply: When we get your advance deposit, and your bottle&label samples, it about 20 days.

Hot Searches