- Product Details

- {{item.text}}

Quick Details

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

China

-

Weight (KG):

-

450 KG

-

Core Components:

-

Laser tube

-

offline working:

-

support

-

Laser power:

-

80-300W

-

Control system:

-

Ruida LCD DSP Control System

-

Motor:

-

Step

-

Driving system:

-

belt

-

worktable:

-

motorized up&down

-

Wifi:

-

available

-

Rotary:

-

available

-

water cooling:

-

CW5200/CW6000

Quick Details

-

Engraving Area:

-

1310x900mm

-

Laser Type:

-

CO2

-

Engraving Speed:

-

500mm/s

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

China

-

Weight (KG):

-

450 KG

-

Core Components:

-

Laser tube

-

offline working:

-

support

-

Laser power:

-

80-300W

-

Control system:

-

Ruida LCD DSP Control System

-

Motor:

-

Step

-

Driving system:

-

belt

-

worktable:

-

motorized up&down

-

Wifi:

-

available

-

Rotary:

-

available

-

water cooling:

-

CW5200/CW6000

Product Description

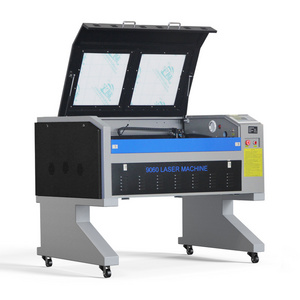

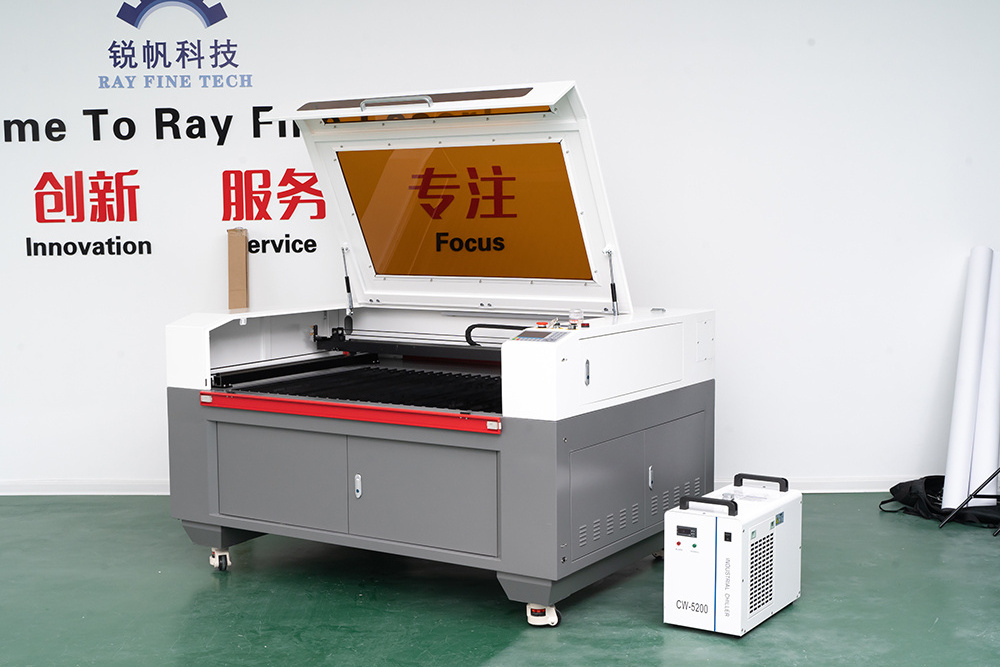

laser co2 machine 6090 90x60 6040 80W Ruida 100w reci 1390 co2 laser engraver cutter

Technical parameter

Applicable materials: wood,MDF,acrylic,plastic,plexiglass,fabric,paper etc and stainless steel

Applicable materials: wood,MDF,acrylic,plastic,plexiglass,fabric,paper etc and stainless steel

|

Model

|

|

|

RF-1390

|

|

|||

|

Focus lens

|

|

|

USA imported D20mm/FCL63.5mm

|

|

|||

|

Power supply

|

|

|

AC220/110V±10% 50/60hz

|

|

|||

|

Working area

|

|

|

1300X900mm

|

|

|||

|

Laser heads quantity

|

|

|

1

|

|

|||

|

Laser power

|

|

|

80-300W

|

|

|||

|

Max moving speed

|

|

|

500mm/s

|

|

|||

|

Working table

|

|

|

Aluminum knife table+Honey comb table

|

|

|||

|

Min shaping character

|

|

|

2mm

|

|

|||

|

Control program

|

|

|

RDCAM(LASERWORK)

|

|

|||

|

Data transfer interface

|

|

|

USB

|

|

|||

|

System environment

|

|

|

WIN7/8/10

|

|

|||

|

Cooling way

|

|

|

Water chiller CW5200

|

|

|||

|

Compatible software

|

|

|

Corel Draw, Auto-CAD

|

|

|||

|

Cutting thickness

|

|

|

0-30 mm (depends on different materials)

|

|

|||

|

Color separation

|

|

|

Separation of cutting up to 256 colors

|

|

|||

|

Red dot pointer

|

|

|

yes

|

|

|||

|

Open door safety

|

|

|

Optional

|

|

|||

|

Packing

|

|

|

Plywood

|

|

|||

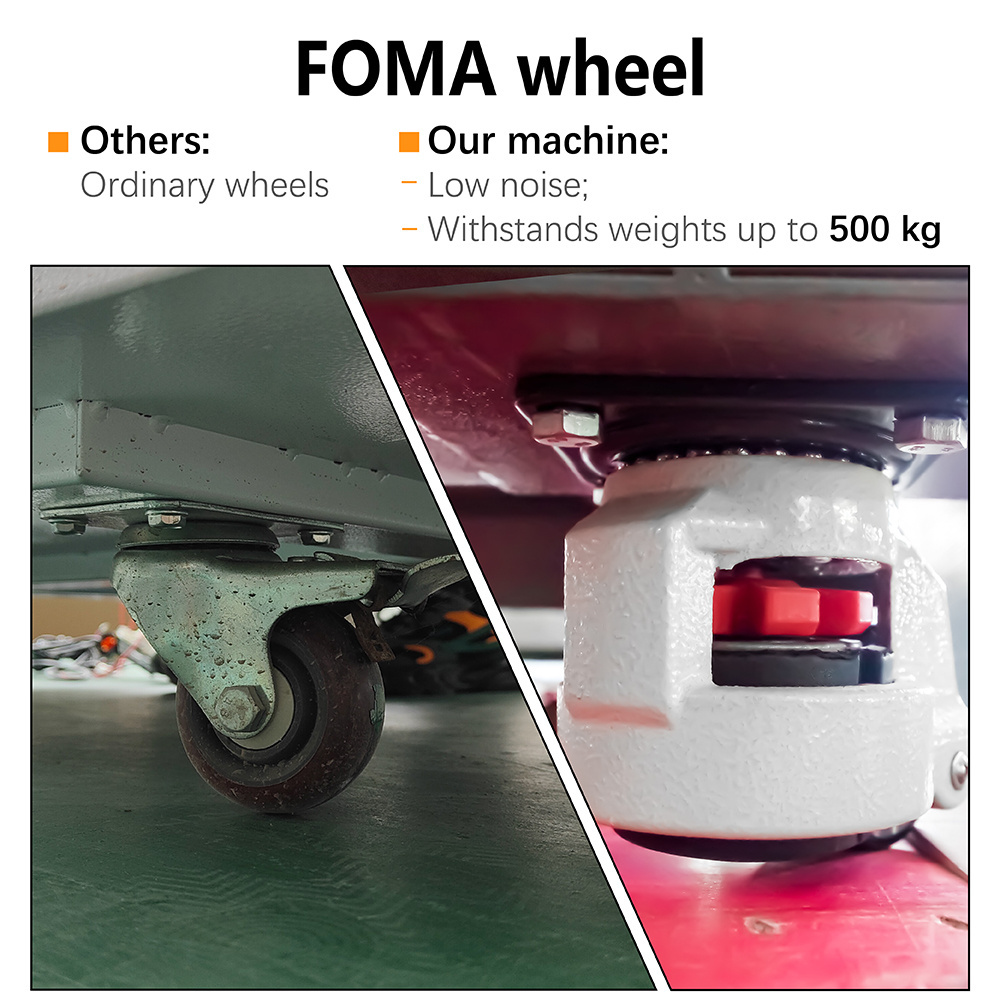

Detailed Images

Packing&Shipping

We have a strict packing process to ensure that the machine will be in good condition during transportation: 1-Ensure each part of

the machine is clean and tidy before packaging;

2-Each accessory is wrapped in a recyclable plastic bag, then wrapped in cardboard;

3-Place the machine neatly (like a cube as much as possible) and add a thicker foam to the corners that are easy to bump;

4-Packing in wooden cases of suitable export standard plywood( fill the corners with recyclable plastic foam),then seal the

case and fasten it with high quality stainless steel nails and steel straps.

5-Then seal the case and fasten it with high quality stainless steel nails and steel straps;

6-We will write the corresponding shipping marks on the cases according to the customer's requirements;

7-Print or spray paint safety sign in wooden box.

the machine is clean and tidy before packaging;

2-Each accessory is wrapped in a recyclable plastic bag, then wrapped in cardboard;

3-Place the machine neatly (like a cube as much as possible) and add a thicker foam to the corners that are easy to bump;

4-Packing in wooden cases of suitable export standard plywood( fill the corners with recyclable plastic foam),then seal the

case and fasten it with high quality stainless steel nails and steel straps.

5-Then seal the case and fasten it with high quality stainless steel nails and steel straps;

6-We will write the corresponding shipping marks on the cases according to the customer's requirements;

7-Print or spray paint safety sign in wooden box.

After Sales Service

We arrange final test before shipment. We run the machine without materials for a few days, and then mark materials for test.After

making sure the machine is the best performance, then ship out the machine

1.

Details english manual book which explain the use of machines and software. Guide the customer proper use, extend product life and reduce energy consumption.

2 .English documents instruction to show you how to install the machine according to each machine of order(including photos and words).

3. Online remote support appointment: after receiving your machine you can make appoint 24 hours before install the equipment. then our engineer supply online support when you are ready to start installment.

4 .Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

2 .English documents instruction to show you how to install the machine according to each machine of order(including photos and words).

3. Online remote support appointment: after receiving your machine you can make appoint 24 hours before install the equipment. then our engineer supply online support when you are ready to start installment.

4 .Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

Related Products

Hot Searches