- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

less than ±1%

-

Voltage:

-

380V/50Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HC

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

550 KG

-

Name:

-

eye drop bottle filling machine

-

Material:

-

SUS304 and 306L stainless steel

-

Filling volume:

-

2-30ml

-

Output:

-

30-50BPM / 60-80BPM

-

Filling Precision:

-

≤±1%

-

Capping Rate:

-

≥99%

-

Stoppering Rate:

-

≥99%

-

Air Supply:

-

1.3 m3/h 0.4-0.8Mpa

-

After-sales Service Provided:

-

filling and capping machine

-

Usage:

-

Beverage Packaging

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

liquid

-

Filling Accuracy:

-

less than ±1%

-

Voltage:

-

380V/50Hz

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HC

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

550 KG

-

Name:

-

eye drop bottle filling machine

-

Material:

-

SUS304 and 306L stainless steel

-

Filling volume:

-

2-30ml

-

Output:

-

30-50BPM / 60-80BPM

-

Filling Precision:

-

≤±1%

-

Capping Rate:

-

≥99%

-

Stoppering Rate:

-

≥99%

-

Air Supply:

-

1.3 m3/h 0.4-0.8Mpa

-

After-sales Service Provided:

-

filling and capping machine

-

Usage:

-

Beverage Packaging

Products Description

product parameters

Brief introuduction

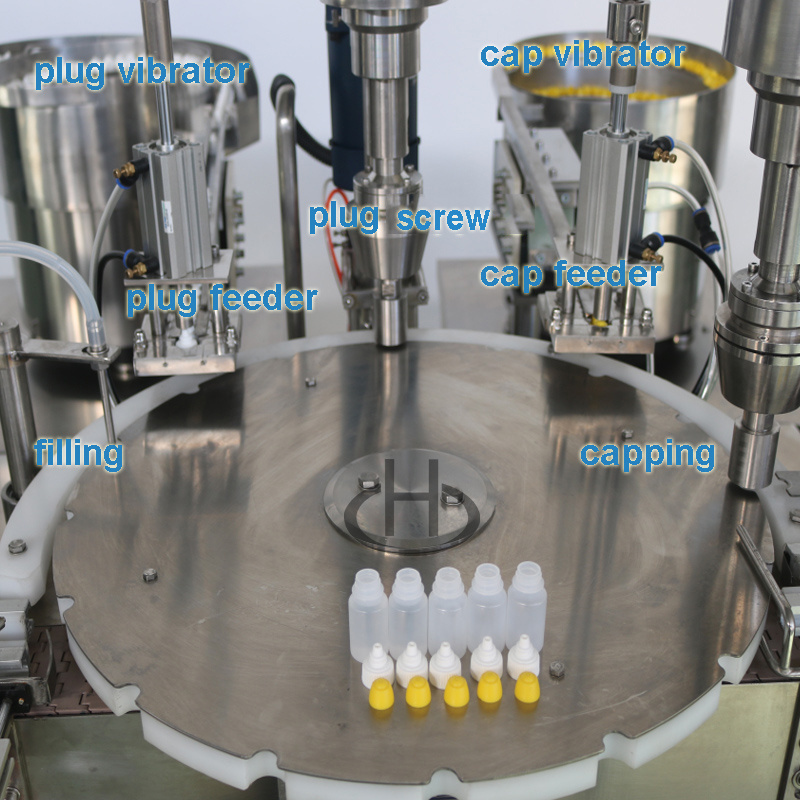

This machine on the basis of the introducing and absorbing foreign advanced technology, our independently R&D special for eye drop filling, stopper feeder,cap feeder,capping(rolling) machine,adopt high precision enclosed cam indexing station with high precision,reliable operation and long time. This indexer has simple structure and does not require maintenance for long-term use.This machine mainly suit for various eye drops bottle liquid filling, stopper press and cap feeder capping(rolling), widly use in the food, pharmaceutical, chemical industry and scientific research fields

characteristic

1,HMI control, operate is intuitive and convenient,PLC control, accurate measurement.

2,Frequency conversion control,speed can adjust arbitrary , automatically count

3,Automatic stop function,no bottle no filling

4,Adopt SUS304 and 316L stainless steel, comply to GMP requirement

5,Whole line can be controlled by single machine or chained

6, Low bottle breaking rate,high qualified rate, small energy consumption

7, Suit for different bottle shapes

8, Work stable, low noise,high accuracy

Process:

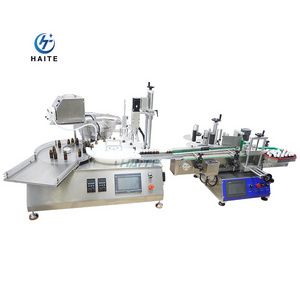

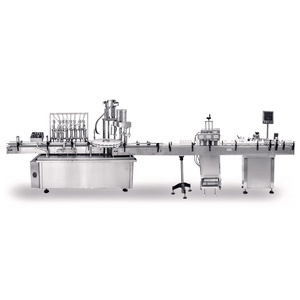

bottle unscrambler-filling/capping-labeling-cartoning

bottle unscrambler -filling/capping-labeling-sleeve/shrink label-cartoning-case packer

2,Frequency conversion control,speed can adjust arbitrary , automatically count

3,Automatic stop function,no bottle no filling

4,Adopt SUS304 and 316L stainless steel, comply to GMP requirement

5,Whole line can be controlled by single machine or chained

6, Low bottle breaking rate,high qualified rate, small energy consumption

7, Suit for different bottle shapes

8, Work stable, low noise,high accuracy

Process:

bottle unscrambler-filling/capping-labeling-cartoning

bottle unscrambler -filling/capping-labeling-sleeve/shrink label-cartoning-case packer

|

Model

|

HCGX/5

|

|

|

|

|||

|

Filling volume

|

0.001-500ml( or customize)

|

|

|

|

|||

|

loading error

|

≤ ±1%(base on water)

|

|

|

|

|||

|

Rotation (rolling) Cover pass rate

|

≥99%

|

|

|

|

|||

|

Output

|

30-50BPM 60-90BPM 90-160BPM

|

|

|

|

|||

|

Filling way Auger filling Power supply

|

380V/50Hz or custmize

|

|

|

|

|||

|

Power

|

Whole filling line 8kw

|

|

|

|

|||

|

Dimension L*W*H

|

Filing machine2 400*1600*2200mm whole filling line

5800/15000*1500*1800mm

|

|

|

|

|||

|

Weigth

|

Filling machine 800kg whole filling line depends

|

|

|

|

|||

|

Pump type

|

Peristaltic pump or ramp pump or Pneumatic plunger pump

|

|

|

|

|||

|

Material

|

Whole machine outside adopt stainless steel 304, touch liquid parts stainless

steel

|

|

|

|

|||

Our Advantages

Hot Searches