- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Weight:

-

300 KG

-

After sale:

-

Video technical support

-

Bussiness:

-

Online support

-

Maintence:

-

Spare parts

-

Service 4:

-

Field maintenance and repair service

-

Max speed:

-

12000sheets per hour

-

Min size:

-

400mm*400mm

-

Max size:

-

1450*1450mm

-

Product name:

-

Servo Laminating Machine

-

Laminating Speed:

-

150meter per min

-

Container:

-

1*40HQ

Quick Details

-

Packaging Type:

-

Plastic film + foam + wooden box + tray

-

Packaging Material:

-

Wood

-

Driven Type:

-

Hydraulic

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Weight:

-

300 KG

-

After sale:

-

Video technical support

-

Bussiness:

-

Online support

-

Maintence:

-

Spare parts

-

Service 4:

-

Field maintenance and repair service

-

Max speed:

-

12000sheets per hour

-

Min size:

-

400mm*400mm

-

Max size:

-

1450*1450mm

-

Product name:

-

Servo Laminating Machine

-

Laminating Speed:

-

150meter per min

-

Container:

-

1*40HQ

High speed servo type laminating machine

Features:

1, Cardboard to corrugated paper, cardboard to cardboard, double fuction

2,Time and effort saving, easy to operate

3,Servo compensation positioning, automatic tracking system

Specification of the YB-1450-1650HS high speed laminating machine and flip flop stacker

| MODEL | YB-1450H | YB-1650H |

| Max Sheet | 1450×1450mm(57''x*57'') | 1650×1650mm (64''x*64'') |

| Min Sheet | 400×400mm | 400×400mm |

| Top Paper Thickness | 150-500g | 150-500g |

| Botton Sheet Thickness |

A,B,C,E,F flute,4 ply corrugated paper(AA,AB,BB) cardboard above 300 GSM |

|

| Max Speed | 150m/min | 150m/min |

| Fitting Precision | ±1mm | ±1mm |

| Air consuption | 1.2m3/min | 1.2m3/min |

| Measurement | 23.6×2.7×3M | 23.6×2.9×3M |

| Machine Power | 30KW | 32KW |

Remarks: The top sheet could be the printed color sheet, filmed paper and uv varnished and paper from offset printing machine.

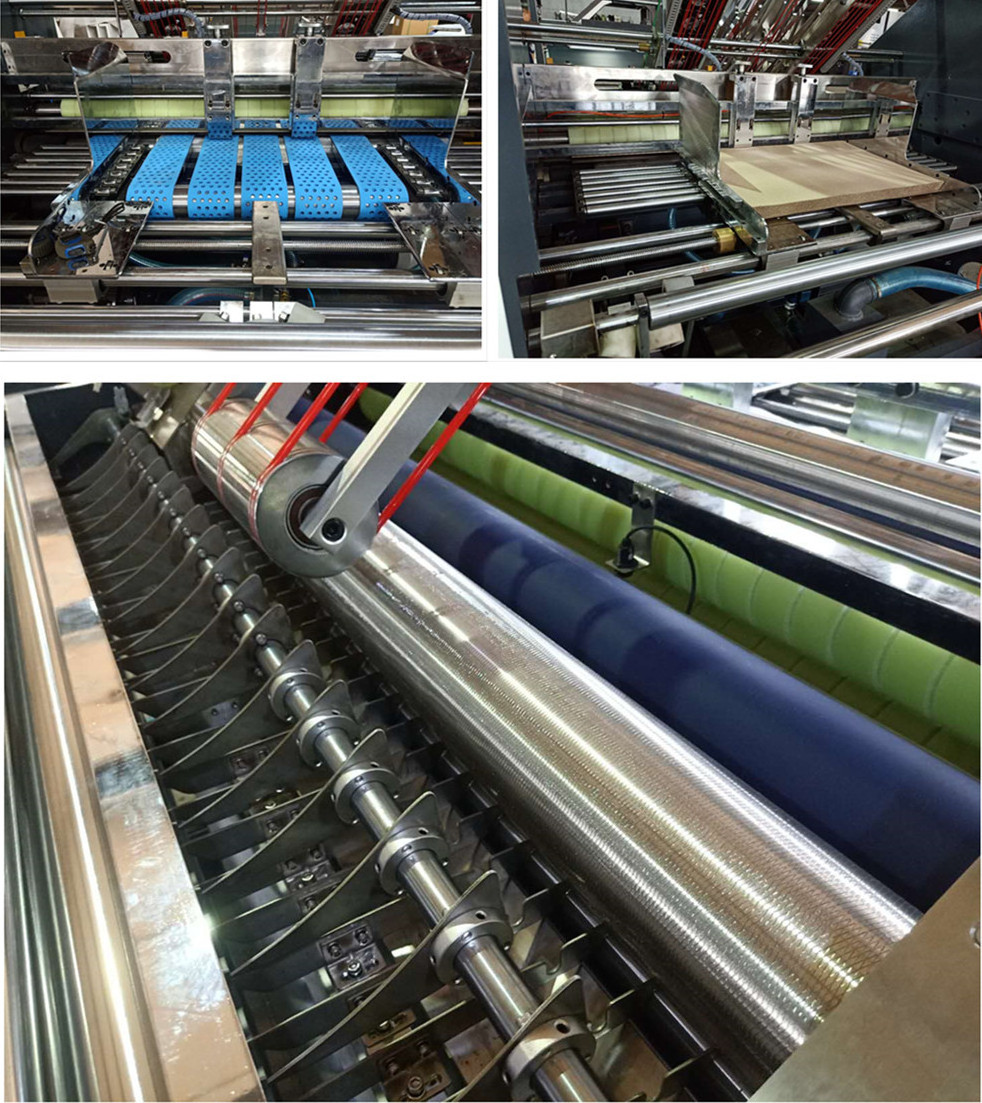

1.Top Feeder Part

4 suckers for picking up paper and 4 suckers for conveying paper to ensure stable and fast paper feeding

Side pulling balls(side lay) ensure the side alignment

Advantages: Whatever direction the top sheet goes, the side-pulling balls will make the sheet go in one line.

2.Bottom feeding and laminating part

Imported brand belt, good suction ability for the bottom sheet feeding.

Stainless steel material roller,never rust, guarentee the amount of glue is even

Servo motor that controll the top sheet Sheet mass detector

3.Electrical part

Famous brand electrical component ensure machine stability, high efficiency and low failure. Using man-machine display interface and PLC combination, display all the information, such as warning, error detect, failures,and operating speed, etc

4. Sheet pressing part

Slope type of the pressing convoyer, humanized design to save effort for the operator collecting the sheets.

Pressing wheels Collecting table