- Product Details

- {{item.text}}

Quick Details

-

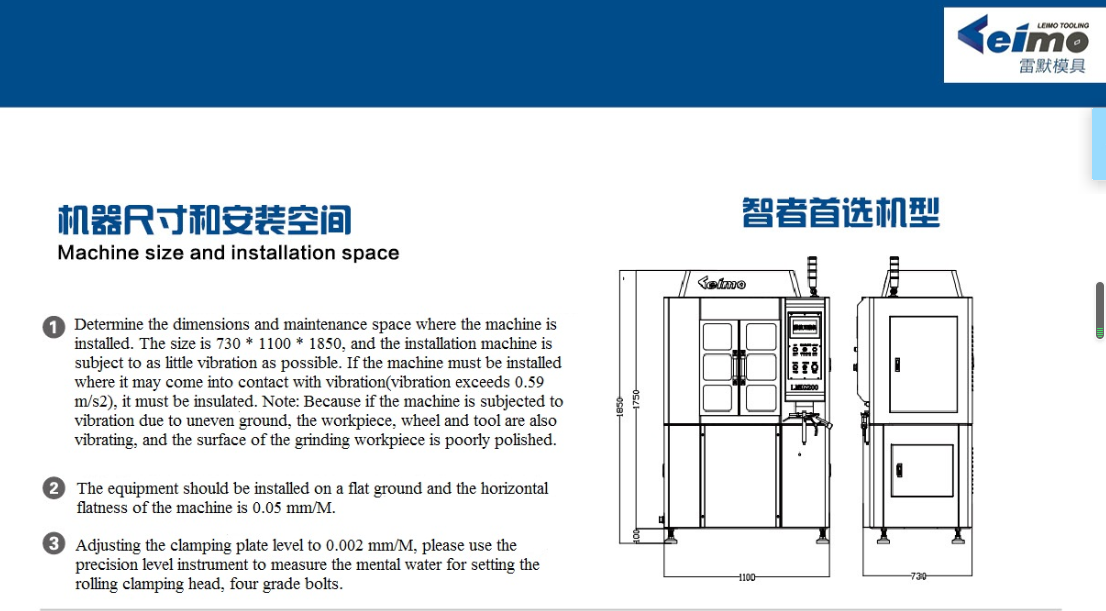

Dimension(L*W*H):

-

730*1100*1850

-

Weight (KG):

-

650

-

Power (kW):

-

0.1

-

Product Keywords:

-

surface grinding machine

-

Max. Grinding Length:

-

300mm

-

Max. Grinding Diameter:

-

260mm

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

LEIMO

-

Voltage:

-

400v

-

Dimension(L*W*H):

-

730*1100*1850

-

Weight (KG):

-

650

-

Power (kW):

-

0.1

-

Product Keywords:

-

surface grinding machine

-

Max. Grinding Length:

-

300mm

-

Max. Grinding Diameter:

-

260mm

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE

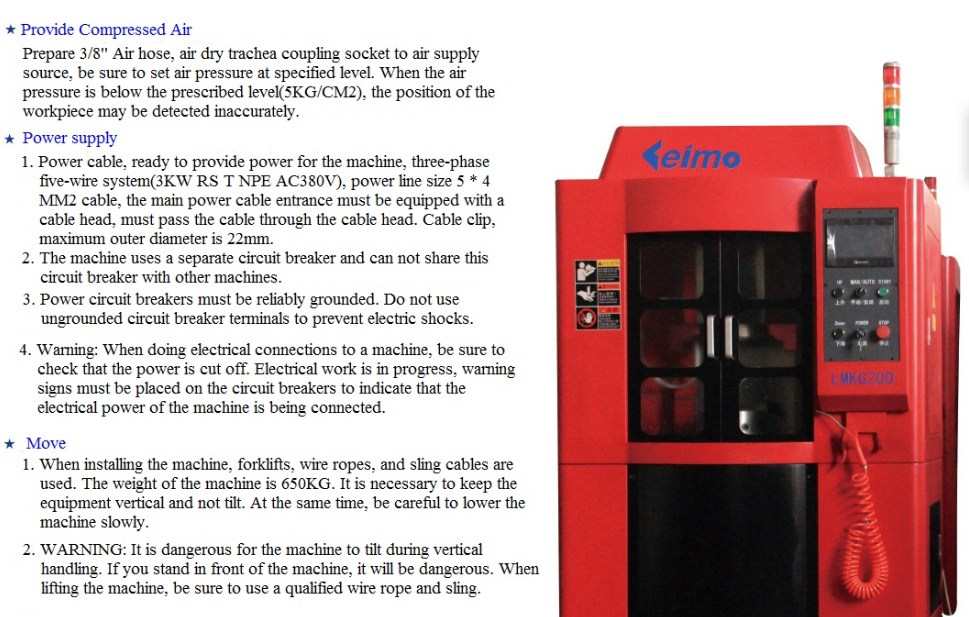

| Model | LMKG200 Type Automatic |

| Grinding precision | 0.005 |

| Grinding procedure | Rough, Middle mill, Precision, Polish |

| Grinding wheel type | CBN 135 |

| Grinding range | 2-260mm |

| Folder range | 2-180mm |

| Spindle stroke | 300mm |

| Grinding stroke | 130mm |

| Bevel edge grinding | YES |

| Grinding Mode | Automatic |

| Lubrication Mode | Automatic |

| Blade Mode | Automatic |

| Laser Detection System | YES |

| Pulse System | YES |

| Spindle Frequency Conversion System | YES |

| Control System | Mitsubishi Controller |

| Control Interface | 7-Inch Touch Screen |

| step motor | Mitsubishi servo motor 0.75KW |

| Grinding Spindle Motor | 3.7kw 380v 3 Phrase Electricity |

| Spindle speed | 0-4800rpm |

| Worktable Motor | 0.1KW |

| Cooling Motor | 0.2kw.380v 3 Phrase Electricity 50 l/m |

| Power Requirements | 3kVA (400V / 50Hz) |

| Three-Phrase Five-wire | |

| Machine Tool Structure | Full vertical Castings, Full Cover Waterproof, Dust Proof, Safety Closure Structure |

| Machine Tool Configuration | Taiwannese Ball Rod, Guide Rail |

| Main Axis Configuration | Japanese Bearings |

| Shape Size |

730*1100*1850 (mm ) (Packing Size:760*1150*2100) |

| Machine Tool Weight | 650kg |

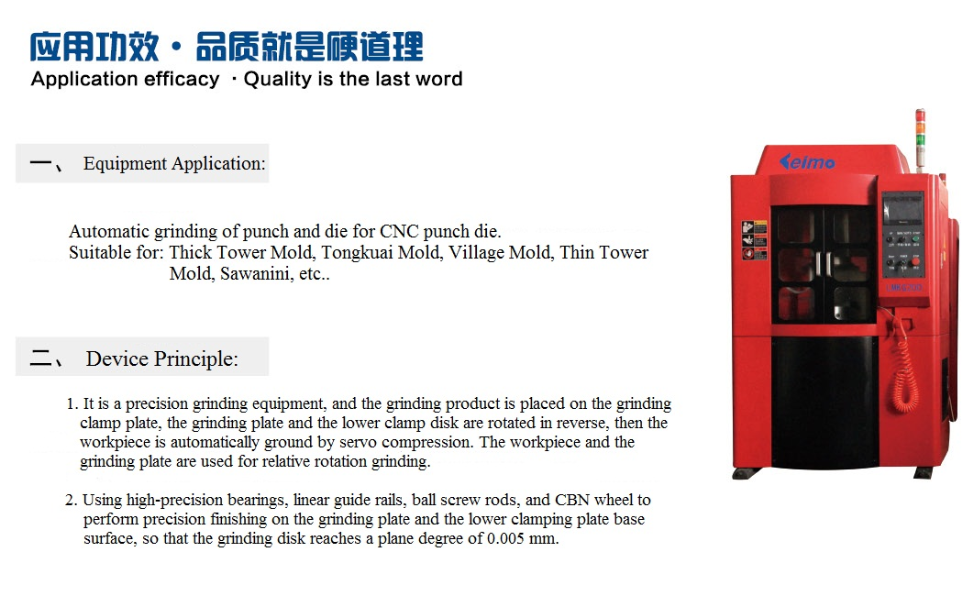

Use of Equipment

It is used for automatic grinding of punch and lower die of NC punch.

Equipment Principle:

1. The grinding machine is a precision grinding equipment. The products are placed on the grinding chuck, the grinding chuck and the lower chuck.

Reverse rotation, automatic grinding of workpiece by servo pressure, relative rotational grinding of workpiece and grinding disc.

2. Use high precision bearing, linear guide rail, ball screw, with CBN grinding wheel pair grinding disc and lower chuck benchmark

Precision trimming is carried out to make the grinding disc reach the flatness of 0.005mm.

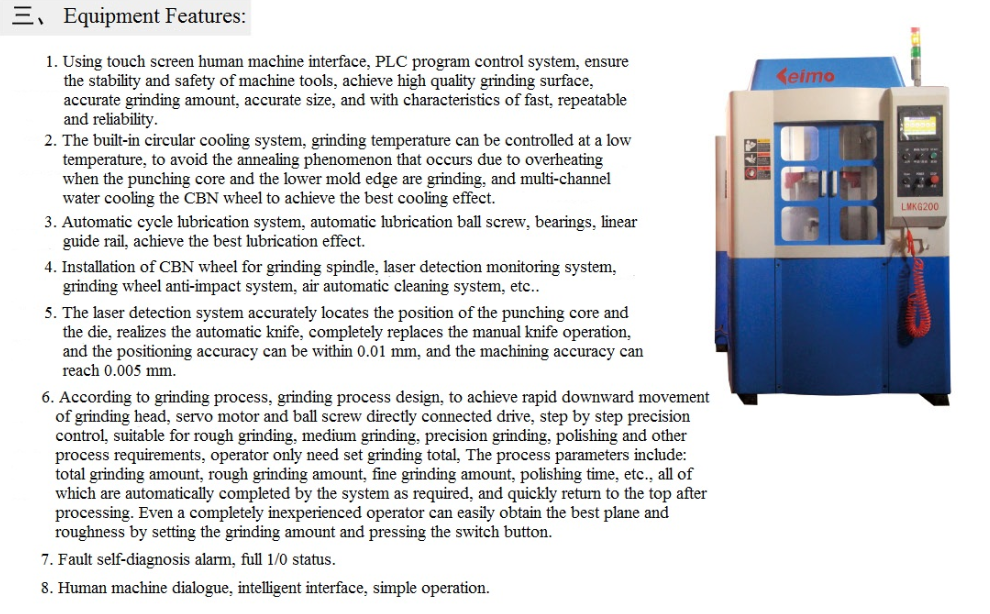

Equipment characteristics:

1. Using touch screen man-machine interface and PLC program control system to ensure the stability and safety of machine tools.

Now high quality grinding surface, precise grinding quantity, precise size, with fast, repeatable, reliable characteristics

Point.

2. Built-in circulating cooling system. Grinding temperature can be controlled at low temperature to avoid core punching and lower die grinding.

Due to the annealing phenomenon caused by overheating, multi-channel water-cooled CBN grinding wheel achieves the best cooling effect.

3. Automatic circulation lubrication system, automatic lubrication of ball screw, bearing and linear guide to achieve the best lubrication

Effect;

4. The grinding spindle is equipped with CBN grinding wheel, laser detection and monitoring system, anti-impact grinding wheel system and automatic air cleaning.

System, etc.

5. Laser testing system precisely locates the position of punch core and lower die, realizes automatic tool alignment, completely replacing hand.

The positioning accuracy can be within 0.01 mm and the processing accuracy can reach 0.005 mm.

6. According to the grinding process, the grinding program is designed to realize the rapid downward movement of the grinding head, which is composed of servo motor and ball.

The screw rod is driven by direct connection and controlled step by step. It is suitable for rough grinding, medium grinding, fine grinding and polishing.

The worker only needs to set the total amount of grinding. The process parameters include: total amount of grinding, rough grinding, fine grinding, polishing time, etc.

All of them are automatically completed by the system according to the requirements, and return to the top quickly after processing. Even a totally inexperienced operator

The best flatness and roughness can be easily obtained by setting the abrasion and pressing the switch button.

7. Fault self-diagnosis and alarm, all I/O status.

8. Man-machine dialogue, intelligent interface and simple operation.