- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

hangyuan

-

Model Number:

-

YQB

-

Place of Origin:

-

Hebei, China

-

Outlet Size:

-

50mm

-

Power:

-

15kw

Quick Details

-

Application:

-

Biofuel Industry, Developing World Water Solutions, District Energy, Food and Beverage Industry, HVAC OEM, Industrial Boilers, Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry

-

Pressure:

-

1.8Mpa

-

Voltage:

-

220v/380v/440v/460v

-

Warranty:

-

1 year

-

Brand Name:

-

hangyuan

-

Model Number:

-

YQB

-

Place of Origin:

-

Hebei, China

-

Outlet Size:

-

50mm

-

Power:

-

15kw

1. Product introduction

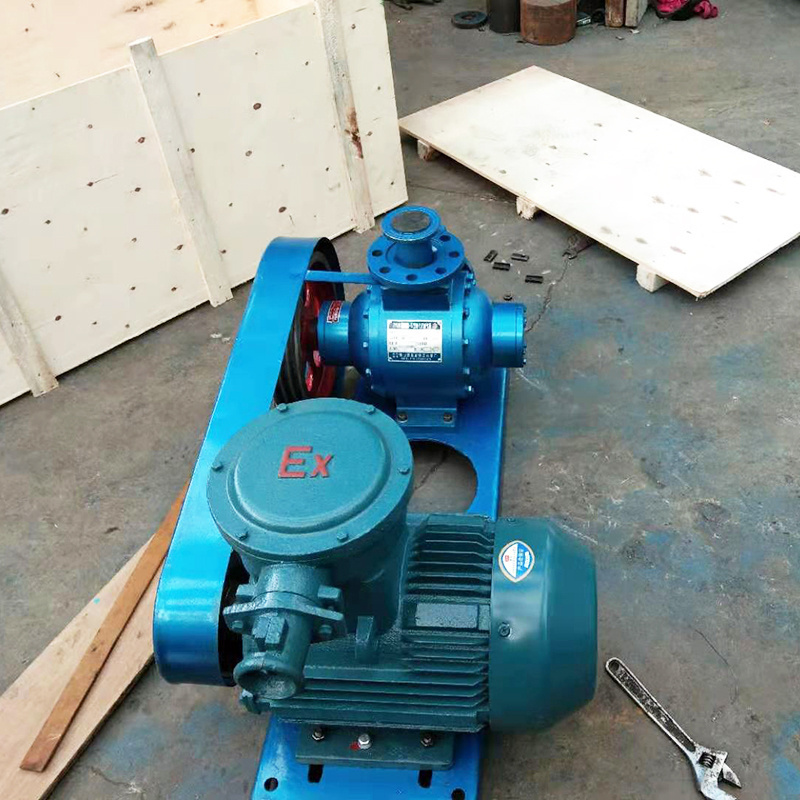

The YQB series liquefied petroleum gas pumps produced by our company are mainly used to transport liquefied petroleum gas, propylene, liquid ammonia, or various volatile liquids and petroleum products with similar properties. The pump is a positive displacement vane pump with an advanced structure. The stator surface is composed of compound curves. Mechanical seals are used at both ends. Each fixed mating end face uses an "O" type seal ring. The matching parts for rotation are made of metal and non-metallic ones. , with the functions of safe and reliable use and multi-purpose in one machine.

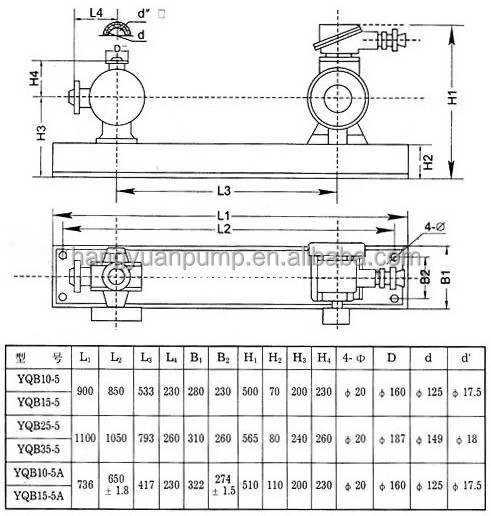

2. Model:

YQB-5 type

3. Model meaning:

YQB one liquid gas pump 5 one pressure rise range (inlet and outlet pressure difference) Rated flow rate of one pump

4. Working principle:

The pump type is a positive displacement vane pump. It works by centrifugal sliding of the blades. The flow rate is related to the rotation speed of the shaft. The inner curved surface of the stator is made of a domestic original compound curve. The stator, rotor, baffle and blades form ten sealed cavities. Since The stator curved surface is a compound curve. When the rotor rotates, the volume of the inlet cavity gradually increases, and a negative pressure is formed to generate suction, thereby sucking in the oil. When the rotor rotates at a certain angle, the volume section gradually decreases, thereby pushing the oil out. There is an oil block between the oil suction chamber and the oil pressure chamber to separate the oil suction chamber and the oil pressure chamber. The blades rely on centrifugal force and the two-baffle structure to closely fit the inner curved surface of the stator, allowing the pump to operate normally under rated conditions.