Tel:+8613637293054(whatsapp)

Wechat:tdfbrush-Ann

Email:ann@tdfbrush.com

|

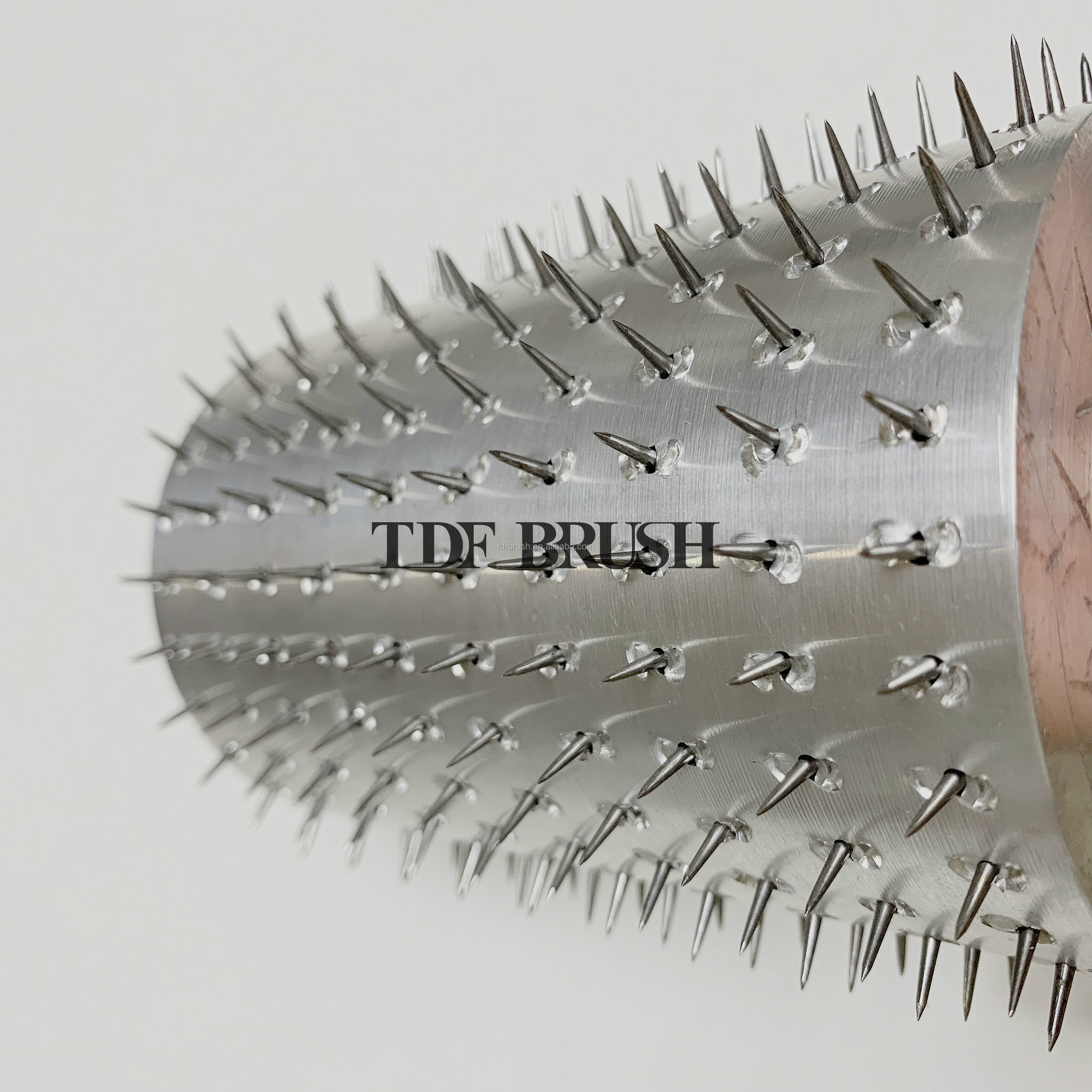

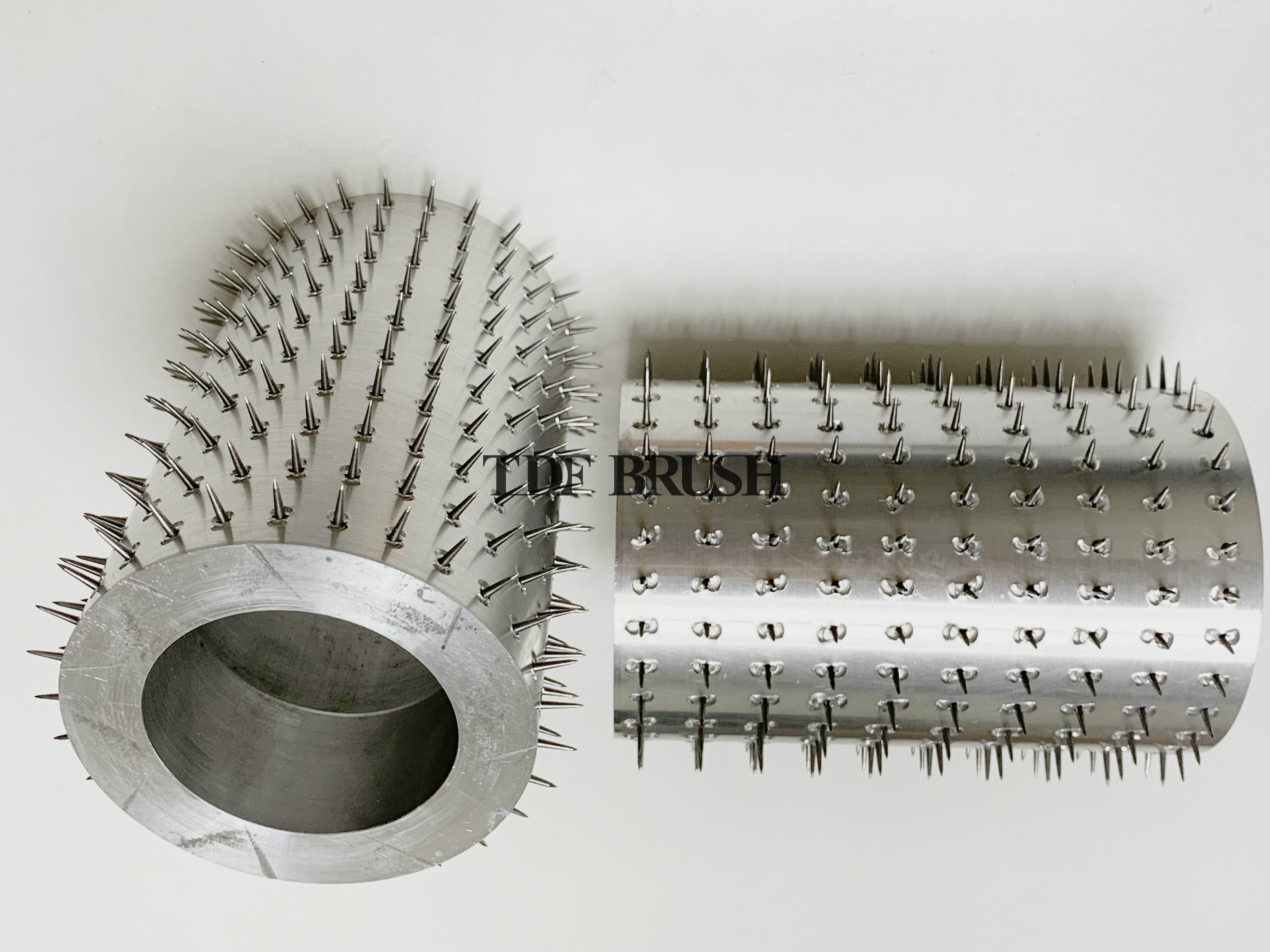

Needle Diameter

|

According to customers' requirements,the minimum diameter is 0.25mm

|

|

Angle of Inclination

|

90°,85°,80°,75°,70°

|

|

Needle Density

|

Up to 100 needles/cm²

|

|

Drill Depth

|

Max 8mm

|

|

Hole Pattern

|

Almost any pattern is possible,linear,spiral-patterns according to the demand

|

|

Diameter of Roller

|

10~350 mm

|

|

Height of Roller

|

Max 300mm

|

|

Roller Material

|

Bronze,brass,aluminium

|

|

Concentricity

|

High concentricity (0.07mm)

|