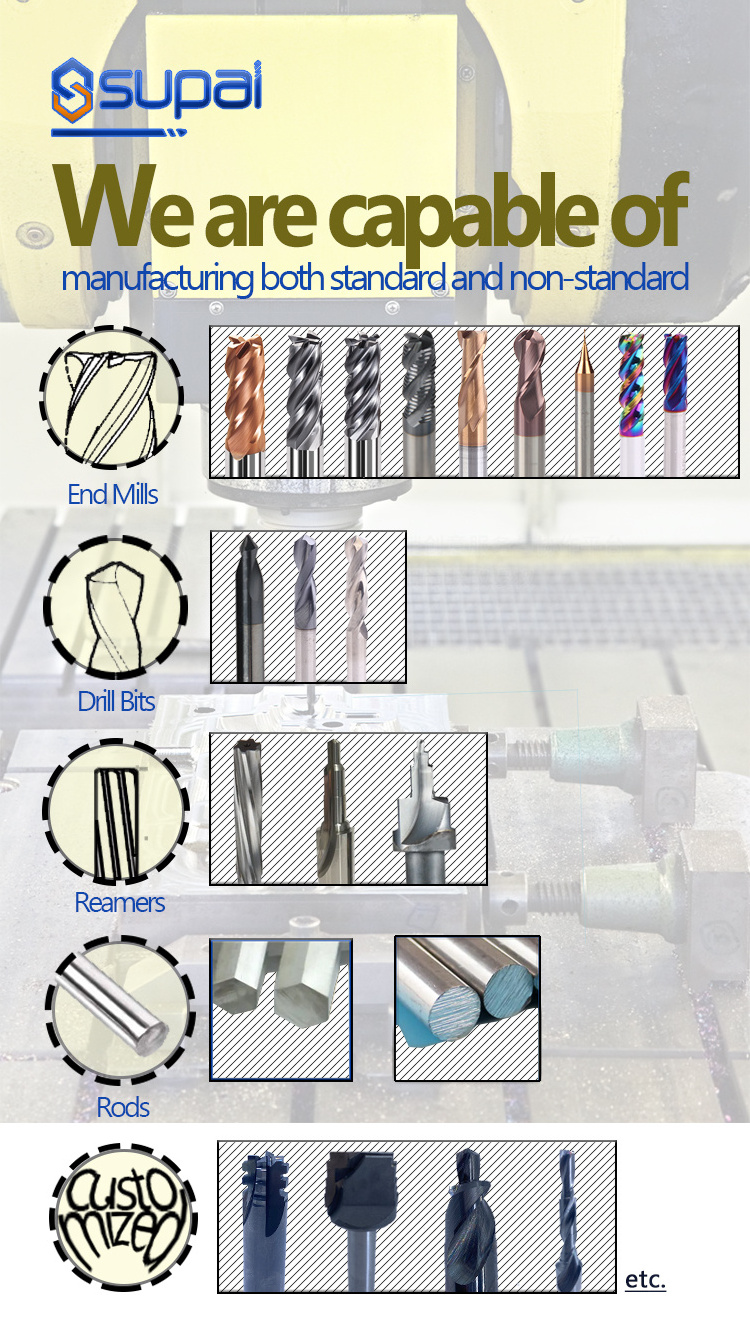

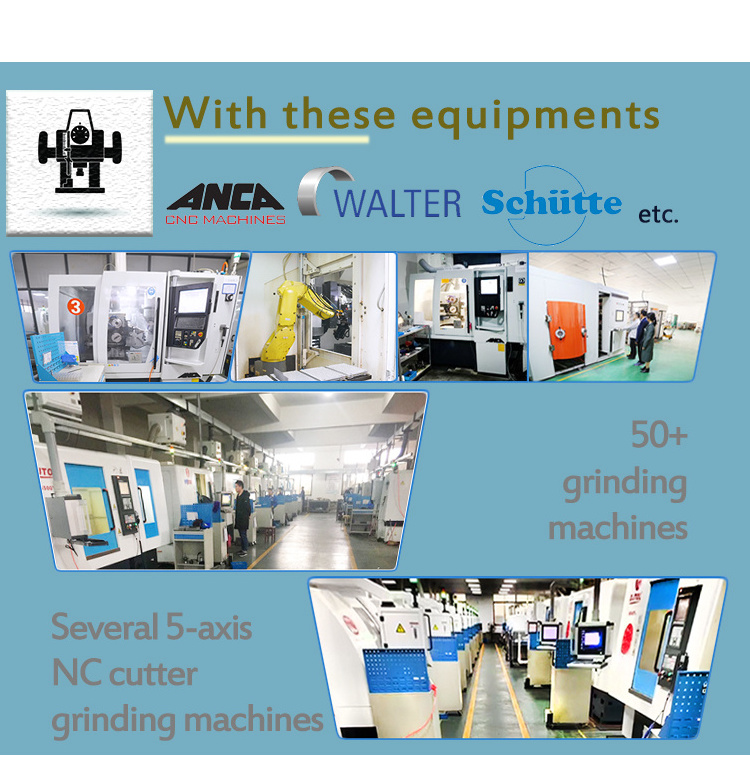

located in Changzhou, Jiangsu Province, is not only a qualified, but a profesional private science and technology enterprise that ranks one of the top 10 local companies of our kind.We have been engaged in designing, manufacturing, and trading the solid carbide tools for over 15 years, with our partners and clients spreaded at home

and abroad.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

supal

-

Model Number:

-

customized model

-

Application:

-

Metal Working Tool

-

MOQ:

-

10

-

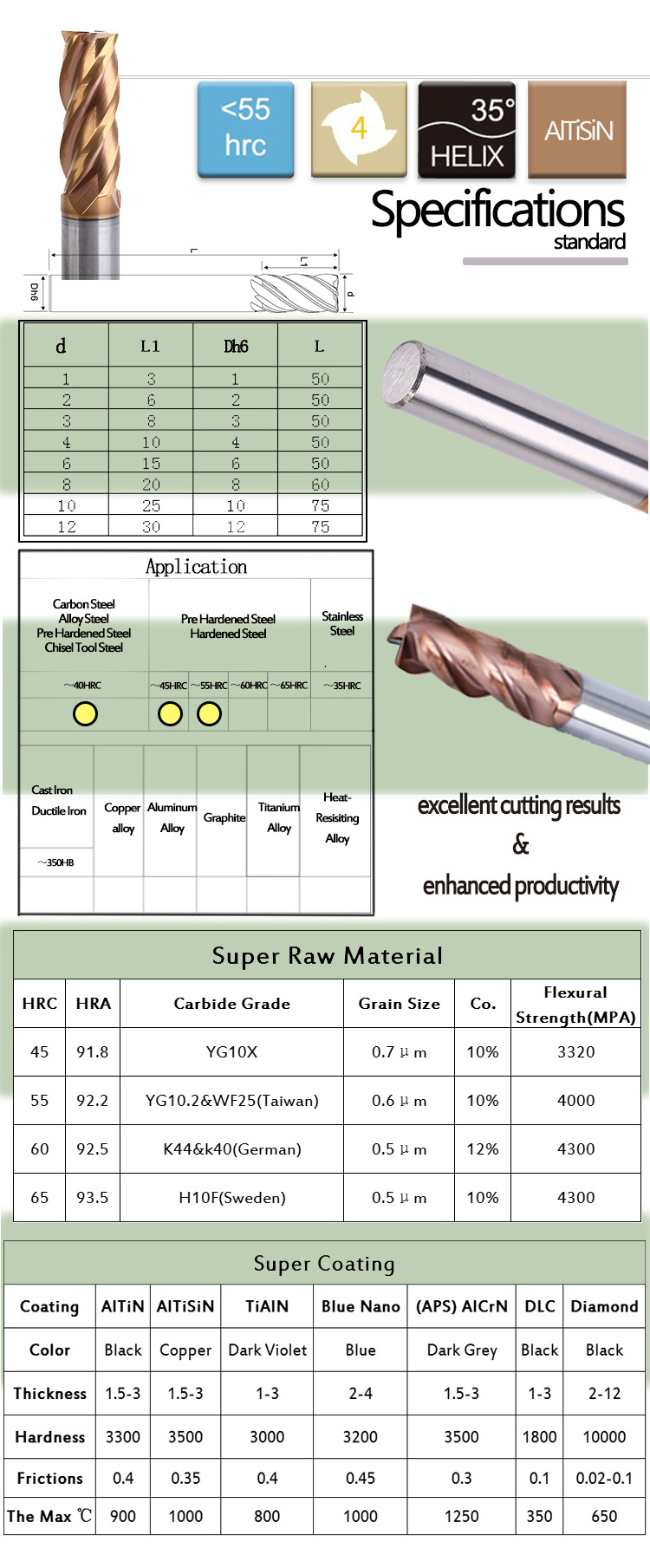

Flute:

-

4

-

Transport:

-

DHL, UPS, FEDEX, TNT, EMS

Quick Details

-

Material:

-

Carbide, HIGH SPEED STEEL

-

Coating:

-

AlTiSiN

-

Warranty:

-

other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

supal

-

Model Number:

-

customized model

-

Application:

-

Metal Working Tool

-

MOQ:

-

10

-

Flute:

-

4

-

Transport:

-

DHL, UPS, FEDEX, TNT, EMS

Descriptions

Supal (Changzhou) Precision Tools Co., Ltd.

FAQ

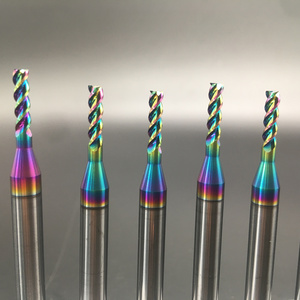

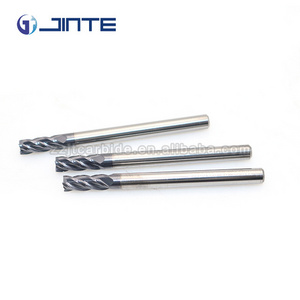

Product Real Shot

NOTICE

Little Tips

In order to obtain a better cutting surface and prolong the tool life, please be sure to use

a tool holder with high precision, high rigidity, dynamic balance and high speed.

* Before using this tool, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting

* The shorter the length of the tool protruding from the chuck, the better. If the protruding amount of the tool is longer, please adjust the speed, feed speed or cutting by yourself.

* If there is abnormal vibration or sound during cutting, please reduce the spindle speed and improve the cutting tool condition.

* Spray or jet cooling is the best trial method for steel cooling, so that the tool can play a better role. It is recommended to use water-insoluble cutting fluid for stainless steel, titanium alloy or heat-resistant alloy.

* The cutting method is affected by the workpiece, machine and software. The above data are for reference only. After the cutting state is stable, reduce the feed rate and increase it by 30%-50%.

Hot Searches