The jaw crusher, is mainly used for the crushing of various ores and large materials with compressive strength not exceeding 320 MPa, and its performance characteristics are large crushing ratio, uniform product particle size, simple structure, reliable performance, easy maintenance and low operating cost.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tianyouchen

-

Dimension(L*W*H):

-

1667*1545*1020

-

Weight:

-

4270 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Crushing Equipment

-

Raw material:

-

Steel

-

Quality:

-

High-Quality

-

Usage:

-

Crushing Work

-

Color:

-

Customerized

-

Crusher type:

-

Jaw Crusher PE250*750

-

Function:

-

Mining Crusher Equipment

-

After-sales Service Provided:

-

Engineers

Quick Details

-

Application:

-

Construction

-

Capacity(t/h):

-

15-35 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tianyouchen

-

Dimension(L*W*H):

-

1667*1545*1020

-

Weight:

-

4270 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Crushing Equipment

-

Raw material:

-

Steel

-

Quality:

-

High-Quality

-

Usage:

-

Crushing Work

-

Color:

-

Customerized

-

Crusher type:

-

Jaw Crusher PE250*750

-

Function:

-

Mining Crusher Equipment

-

After-sales Service Provided:

-

Engineers

Product Description

Crushing equipment includes jaw crusher, impact crusher, hammer crusher and other crushing equipment. Among them, the jaw crusher is the longest used and the most widely used crushing equipment. The traditional crushing equipment has many models and large output, and is the first choice for mine crushing equipment.

Operating Feature

1, Low noise, less dust.

2, Its crushing ratio is large, the product particle size is uniform.

3, Simple structure, reliable work, low operating costs.

4, The lubrication system is safe and reliable, the parts are easy to replace, and the equipment is simple to maintain.

5, The crushing chamber is deep and no dead zone, improve the feeding capacity and output.

6, Equipment energy saving: single-machine energy saving 15% ~ 30%, system energy saving more than double.

7, Discharge port adjustment range is large, can meet the requirements of different users.

Work Principle

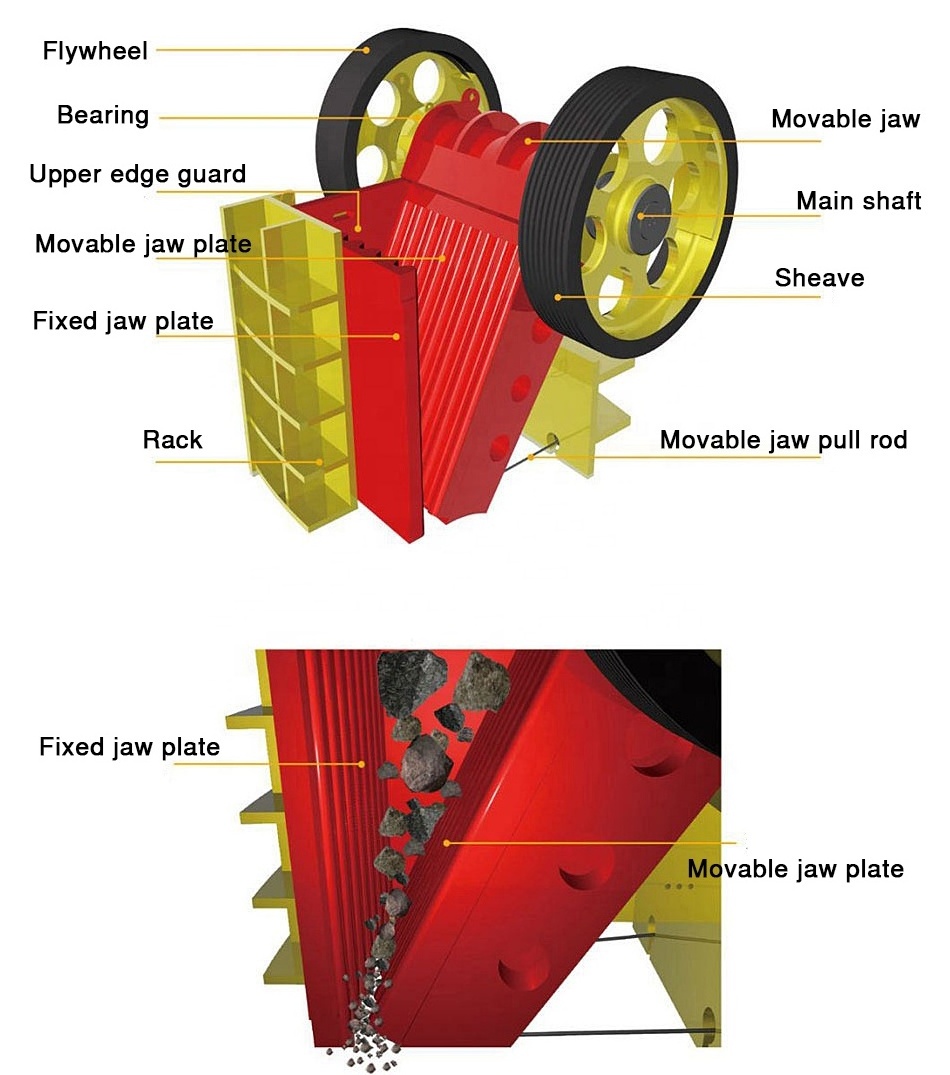

The working part of the jaw crusher is two jaw plates, one is a fixed jaw plate, vertically fixed on the front wall of the body, the other is an active jaw plate, the position is inclined, and the fixed jaw plate forms a large and small crushing chamber. The movable jaw plate makes periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, the material enters the crushing chamber, and the finished product is discharged from the lower part; When approached, the material installed between the two jaw plates is crushed by extrusion, bending and splitting.

Application Fields

Jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other departments. According to the width of the feed port, it is divided into three types: large, medium and small. The feed port width is greater than 600 MM for large machines, the feed port width is 300-600 MM for medium-sized machines, and the feed port width is less than 300 MM for minicomputers. The jaw crusher is simple in structure, easy to manufacture and reliable in operation, and is often used in railway, highway, water conservancy, mining, building materials, chemical industry, metallurgy and other fields.

Crusher can be broken material is very wide, more than 200 materials, such as stone field is river pebbles, pebbles, granite, basalt, marble, limestone, quartz stone, stone hardness of not more than 250 MPa of various materials and ore fields of gold and silver ore, lead zinc ore, limonite, hematite, manganese ore, copper, rare earth ore and other non-ferrous metals, ferrous metals and precious metals.

Technical Parameters

|

Model

|

Maximum feeding force(mm)

|

Discharge port adjustable range(mm)

|

Time yield (t/h)

|

Motor power (kw)

|

|

PE150*250

|

125

|

10-40

|

1-4

|

Level 4 5.5kw

|

|

PE200*300

|

180

|

15-50

|

2-8

|

Level 4 7.5kw

|

|

PE220*350

|

200

|

15-70

|

3-13

|

Level 4 11kw

|

|

PE250*400

|

210

|

20-80

|

5-20

|

Level 4 15kw

|

|

PE300*500

|

290

|

30-100

|

10-35

|

Level 4 18.5kw

|

|

PE400*600

|

350

|

40-100

|

18-50

|

Level 6 30kw

|

|

PE500*750

|

425

|

50-120

|

30-90

|

Level 6 55kw

|

|

PE600*900

|

500

|

65-180

|

50-160

|

Level 6 75kw

|

|

PE750*1060

|

685

|

100-250

|

120-192

|

Level 6 110kw

|

|

PE900*1200

|

850

|

150-280

|

140-264

|

Level 6 110kw

|

|

Model

|

Maximum feeding force(mm)

|

Discharge port adjustable range(mm)

|

Time yield (t/h)

|

Motor power (kw)

|

|

PEX100*600

|

80

|

10-40

|

1-8

|

Level 4 7.5kw

|

|

PEX150*750

|

120

|

10-40

|

8-25

|

Level 4 15kw

|

|

PEX250*750

|

210

|

15-50

|

13-35

|

Level 6 22-30kw

|

|

PEX250*1000

|

210

|

15-50

|

15-50

|

Level 6 30-37kw

|

|

PEX250*1200

|

210

|

15-50

|

20-60

|

Level 6 37kw

|

|

PEX300*1300

|

250

|

20-90

|

28-98

|

Level 6 55kw

|

We produce various models of coarse and fine jaw crusher to meet the needs of customers using different models of equipment in various fields, and we provide customized equipment just to get your needs.

Production line

The jaw plate is the main working part, which is subjected to greater impact and extrusion pressure, so the wear rate is relatively high. Our company's jaw plate is made of high manganese steel, good casting performance, strong wear resistance, long service life.

Jaw crusher can break a variety of stone, such as granite, basalt, marble, limestone, gold and silver ore.

The movable jaw moves back and forth on the fixed jaw, and the material put in from the upper chamber is compressed between the two jaws, smashing it into smaller pieces. When the moving jaw leaves the fixed jaw, the broken material is discharged from the bottom outlet. Customers can adjust the discharge port according to demand.

Packing & Delivery

1.The equipment and wearing parts are packed in plastic film and wooden box.

2.FCL:Shipped in standard export container.

3.Various packaging methods can be provided according to customer requirements, such as: fumigation-free wooden boxes, steel boxes, etc.

We ship the goods to China's main seaports, such as Qingdao, Tianjin, Shanghai, etc., and then ship the equipment to your country by sea.

Maybe you are interested in

Due to fluctuations in the market price of raw materials, this price is for reference only.

Hot Searches