- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

5000*600*1200mm

-

Weight:

-

900 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Shapati molding machine

-

Function:

-

Easy Operating

-

Application:

-

Food Industry Machinery

-

Material:

-

Stainless Steel

-

Final product:

-

Tortilla Chapati Roti .etc

-

Usage:

-

Commercial Usage

-

Feature:

-

High Efficiency Easy Operation

-

Advantage:

-

Easy Operation Low Cost

-

Operation:

-

Automatic Control

-

Packing:

-

Wooden Box

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JOCONN

-

Voltage:

-

220/380v

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

5000*600*1200mm

-

Weight:

-

900 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Shapati molding machine

-

Function:

-

Easy Operating

-

Application:

-

Food Industry Machinery

-

Material:

-

Stainless Steel

-

Final product:

-

Tortilla Chapati Roti .etc

-

Usage:

-

Commercial Usage

-

Feature:

-

High Efficiency Easy Operation

-

Advantage:

-

Easy Operation Low Cost

-

Operation:

-

Automatic Control

-

Packing:

-

Wooden Box

|

1

|

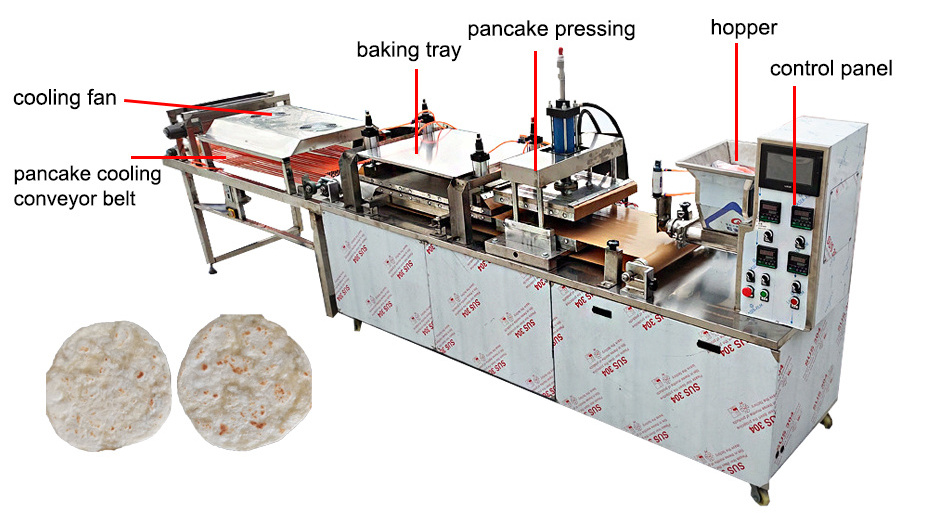

Higher standard control for machine than manual or semi auto machine, it can

cutting dough ball

,

shaping bread

and

baking

and

cooling temperature

,conveying as a whole production line

|

|

2

|

The baking time, baking temperature, bread thickness and working speed are adjustable by control box

|

|

3

|

It can make bread baking patterns or without patterns.

|

|

4

|

well formed bread, the bread shape is uniform in thickness, smooth and round, heated evenly and tastes good

|

|

5

|

High efficiency, over thousands pieces of cakes per hour

|

|

6

|

bread

diameter

(8-50cm), thickness (0.3-3mm), color and speed of this machine can be adjusted.

|

|

7

|

the product made by this machine can be

stored at low temperature for one month

(frozen for one year).

|

|

Capacity

|

2500-3000pcs/h

|

|

Power

|

2.2kw/380V

|

|

Product diameter

|

20cm

|

|

Size

|

5000*600*1200mm

|

|

Weight

|

900kg

|

|

flat bread size

|

5~70cm

|

|

Thickness

|

0.3~10mm

|

1.Dough cutting

Put the mixed dough into the hopper, the auger will squeeze out the dough and cut it into pieces of the same size

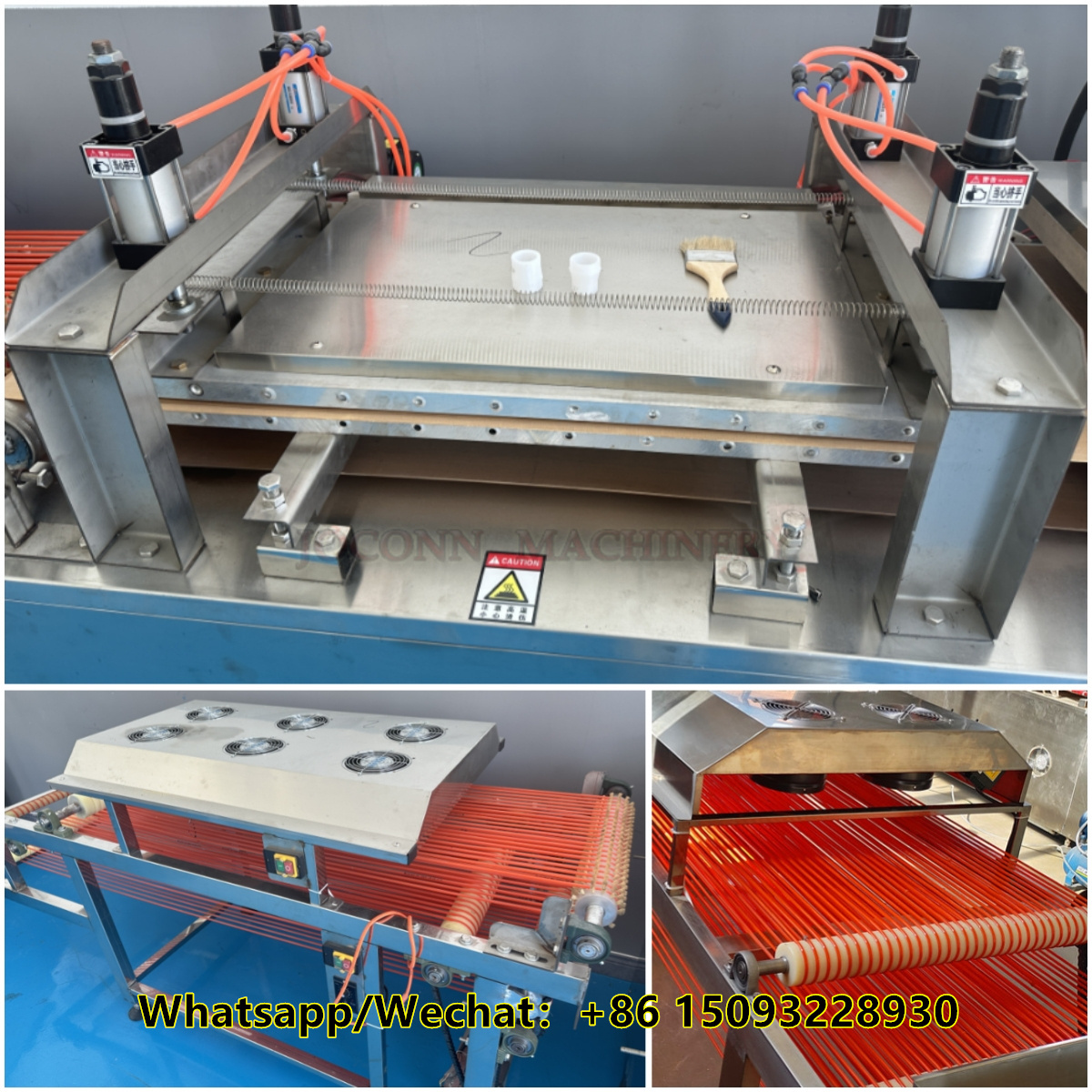

2.Press bread molding

Transfer the cut dough to the center of the pressure plate. The pressure plate will press the dough into a pancake shape and heat it until it is evenly thin and thick.

3.Baking pan

Transfer the shaped dough to the baking pan for double-sided heating. The heat is adjustable.

4.Cooling fan

Can be equipped with cooling fan and automatic turning bread and powder box

5.Multi-layered conveyor belt

Convenient to take the bread and a

ccelerate cooling

6.Control panel

Hydraulic switch, emergency stop switch, pressure plate, baking pan switch temperature control and adjustment

Hot Searches