- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROKIN

-

Model Number:

-

RKJD-350

-

Voltage:

-

AC 380V, 50Hz

-

Dimension(L*W*H):

-

6500*2000*1700mm

-

Weight:

-

6000 KG

-

Marketing Type:

-

New Product 2021

-

Max Speed:

-

220-600pcs/min

-

Model:

-

RKJD-350

-

Speed:

-

200-600pcs/min

-

Paper bag length:

-

160-715mm

-

Paper bag width:

-

70-350mm

-

Side insert width:

-

20-120mm

-

Bag mouth height:

-

15/20mm

-

Paper thickness:

-

35-80g/m2

-

Paper roll width:

-

100-980mm

-

Paper roll diameter:

-

Dia200-1000mm

-

Inner diameter of the paper rol:

-

Dia 76mm

Quick Details

-

Machine Type:

-

Paper Bag Forming Machine

-

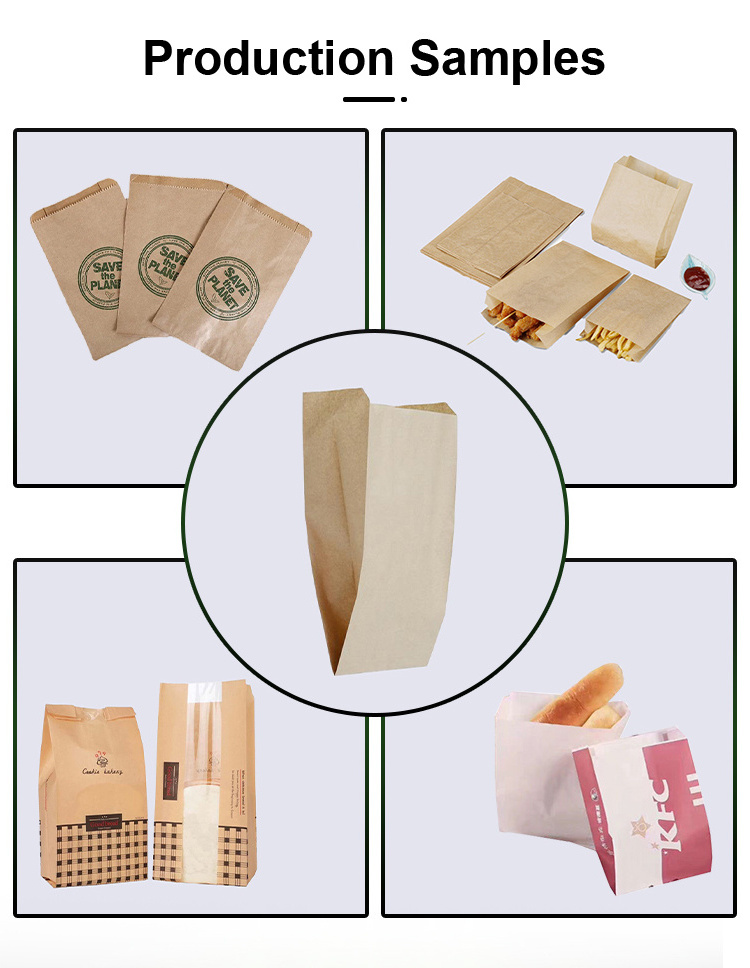

Bag Type:

-

food bag/shopping bag

-

Material:

-

paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROKIN

-

Model Number:

-

RKJD-350

-

Voltage:

-

AC 380V, 50Hz

-

Dimension(L*W*H):

-

6500*2000*1700mm

-

Weight:

-

6000 KG

-

Marketing Type:

-

New Product 2021

-

Max Speed:

-

220-600pcs/min

-

Model:

-

RKJD-350

-

Speed:

-

200-600pcs/min

-

Paper bag length:

-

160-715mm

-

Paper bag width:

-

70-350mm

-

Side insert width:

-

20-120mm

-

Bag mouth height:

-

15/20mm

-

Paper thickness:

-

35-80g/m2

-

Paper roll width:

-

100-980mm

-

Paper roll diameter:

-

Dia200-1000mm

-

Inner diameter of the paper rol:

-

Dia 76mm

|

Model

|

RKJD-250

|

RKJD-350

|

|

Paper bag cutting length

|

110-450mm

|

155-715mm

|

|

Paper bag length

|

105-445mm

|

150-710mm

|

|

Paper bag width

|

70-250mm

|

70-350mm

|

|

Side insert width

|

20-120mm

|

20-120mm

|

|

Bag mouth height

|

15/20mm

|

15/20mm

|

|

Paper thickness

|

35-80g/m2

|

35-80g/m2

|

|

Max. Paper bag speed

|

500pcs/min

|

700pcs/min

|

|

Paper roll width

|

100-760mm

|

100-980mm

|

|

Paper roll diameter

|

Dia1000mm

|

Dia1000mm

|

|

Inner diameter of the paper roll

|

Dia 76mm

|

Dia 76mm

|

|

Power

|

10KW

|

20KW

|

|

Weight

|

4500 KGS

|

6500 KGS

|

|

Dimension

|

L6800*W1600*H1600mm

|

L7500*W2300*H1800mm

|

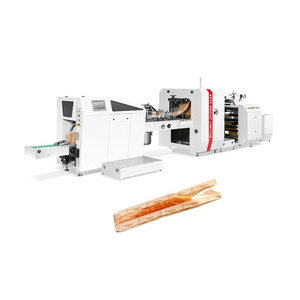

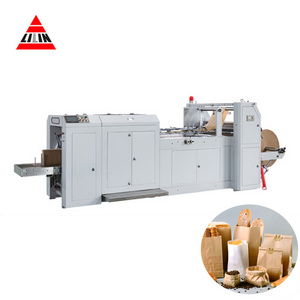

V bottom paper bag machine is applied to produce paper bags for fast food restaurant, grocery stores, etc. ROKIN paper bag forming machine is an ideal machine for making paper bags of various sizes. The fully automatic paper bag making machine is easy to operate, high efficient, stable, accurate and labor cost saving. It’s a completed paper bag production machine, including all processes in one line. To optimize the kraft paper bag machine performance, we adopt Yaskawa PLC and servo motor, SICK photoelectric sensor, Eaton low voltage electrical apparatus and so on.

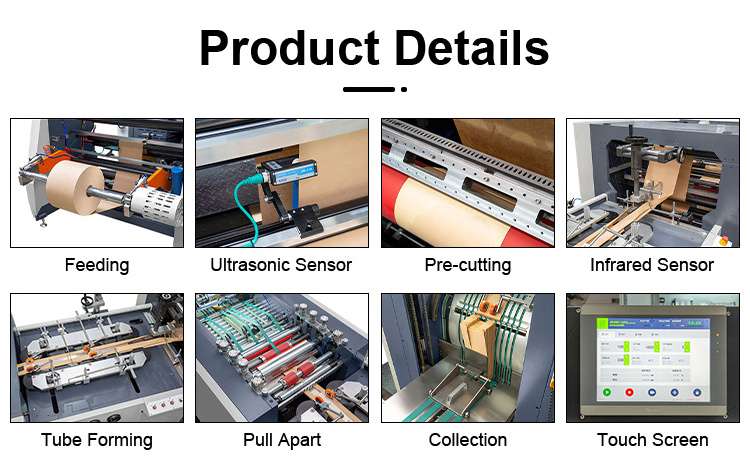

Product Features and Details:

1. The human-machine touch screen interface, the work condition can be shown in real- time.

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Material loading and unloading adopts pneumatic or hydraulic lifting structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

3. Material loading and unloading adopts pneumatic or hydraulic lifting structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6.Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don't stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple, more time saving.

8. Glue roller air defense coating control,avoid gluing on besmear brushs hub surface directly, reduce unnecessary trouble.

9. Accurate color tracking system, automatic alarm prompt when color is wrong.

10. Adjustable forming mould structure (side sealing is above the forming mould).

11. Handle production unit, paper handle cutting and gluing are all controlled by servo motor.

8. Glue roller air defense coating control,avoid gluing on besmear brushs hub surface directly, reduce unnecessary trouble.

9. Accurate color tracking system, automatic alarm prompt when color is wrong.

10. Adjustable forming mould structure (side sealing is above the forming mould).

11. Handle production unit, paper handle cutting and gluing are all controlled by servo motor.

Wenzhou Rokin Machinery CO. Ltd

is the manufacturer of full automatic paper bag machine, square bottom paper bag machine, v bottom paper bag machine, case making machine, cardboard slitting machine and related auxiliary equipment, etc.

Q: Are you manufacturer or trading company?

A: We are the manufacturer and have over 200 workers.

Q: Where is your factory located? May I have a visit?

A: Warmly welcome! Our factory is located in Wenzhou city.

Q: How is the quality of your machine?

A:We are in machine manufacturer over 20 years and regard quality as the life of the enterprise.We choose the world famous manufacturers as our suppliers. And besides, we have our own quality inspector.Machine parts are checked one by one according to the drawings! Good quality and good after-sales help us obtain good reputation in the international market! We have a technical team of seven person and at the same time cooperate with other Research Institutes.We are committed to providing customers with the best packaging machine.

Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper. Second, sizes of the paper bag, thickness of paper.

Send sample bag picture if available. Then we will recommend the right machine to you!

Q: Where is your factory located? May I have a visit?

A: Warmly welcome! Our factory is located in Wenzhou city.

Q: How is the quality of your machine?

A:We are in machine manufacturer over 20 years and regard quality as the life of the enterprise.We choose the world famous manufacturers as our suppliers. And besides, we have our own quality inspector.Machine parts are checked one by one according to the drawings! Good quality and good after-sales help us obtain good reputation in the international market! We have a technical team of seven person and at the same time cooperate with other Research Institutes.We are committed to providing customers with the best packaging machine.

Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper. Second, sizes of the paper bag, thickness of paper.

Send sample bag picture if available. Then we will recommend the right machine to you!

Hot Searches