- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

45-90HRC

-

OEM:

-

YES

-

Format of drawing:

-

CAD, PDF AI PSD etc

-

Module Life:

-

2-6 Years

-

Size:

-

various size available, customized

-

Treatment:

-

Heat treatment

-

Material:

-

H13, Stainless steel, 9CrSi, 55SiCr or by custom

Quick Details

-

Type:

-

Twin shafts waste recycling shredder

-

Brand Name:

-

XINMECHAN

-

Application:

-

all purpose shredder machine parts knife

-

Hardness:

-

45-90HRC

-

OEM:

-

YES

-

Format of drawing:

-

CAD, PDF AI PSD etc

-

Module Life:

-

2-6 Years

-

Size:

-

various size available, customized

-

Treatment:

-

Heat treatment

-

Material:

-

H13, Stainless steel, 9CrSi, 55SiCr or by custom

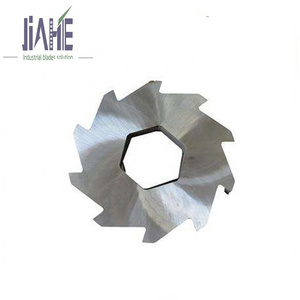

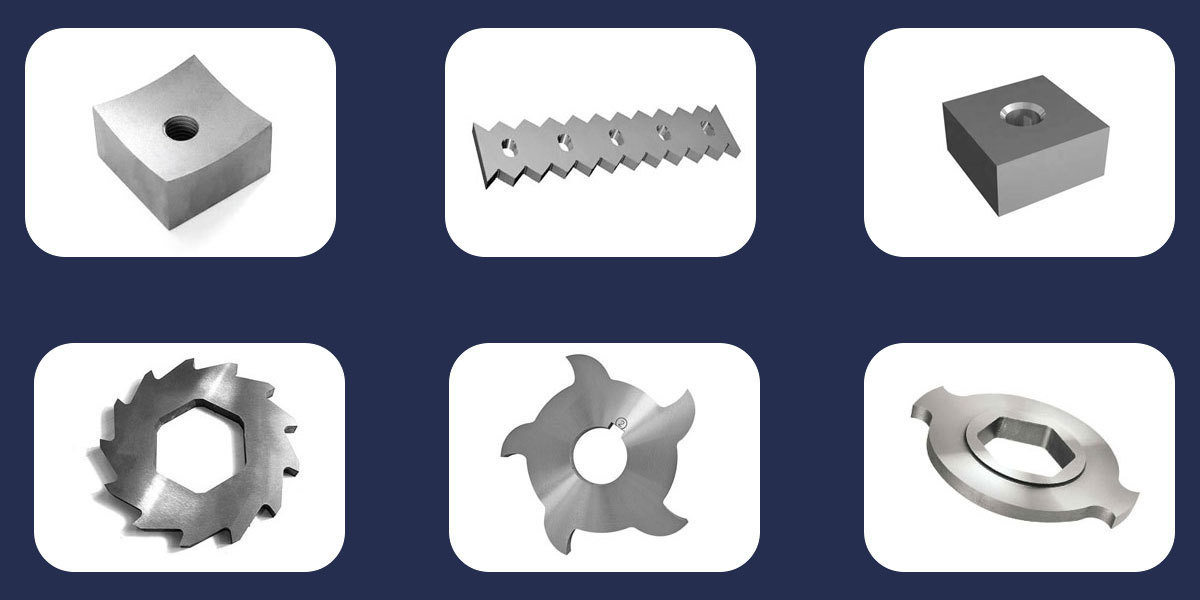

Our shredder blades are specially designed for shredding machines that process a wide range of materials, including paper, cardboard, plastics, rubber, tires, wood, electronic waste, household waste lithium batteries and metal. Our blades are made of high-strength alloy or stainless steel, ensuring long-lasting cutting performance and durability.

|

Size

|

customized

|

|

Material

|

H13,Cr12MoV, SKD-11,D2,1.2379, high alloy tool steel

|

|

Hardness

|

58-60 HRC

|

|

Tolerance

|

Exceed OEM specification

|

|

OEM Service

|

Available

|

|

Packing

|

Wooden boxes, standard export packaging

|

|

Application

|

Shredder blades for Plastic, Rubber, Metal, Waste Recycling

|

|

Delivery time

|

30 days after deposit be received

|

Features:

1. High-strength alloy or stainless steel construction.

2. Precision cutting edges for efficient shredding.

3. Compatibility with various types and models of shredding machines.

4. Easy installation and replacement.

5. Competitive pricing for high-quality products.

Whether you are a shredding machine manufacturer or a user, our shredder blades offer superior cutting performance and durability to help you achieve efficient and secure shredding operations.

Please contact us for more information and customization options.

Welcome to our store, where we specialize in manufacturing high-quality shredder blades for customers worldwide. As a professional shredder blade manufacturer, we are dedicated to delivering exceptional products and services that meet the needs of our customers.

Our state-of-the-art production facility is equipped with advanced machinery and equipment,

allowing us to manufacture a wide range of shredder blades in different sizes and configurations.

We use only the highest quality materials, including premium tool steels and carbides, to ensure our blades meet the highest standards of durability and performance.

Our team of skilled technicians and engineers has a wealth of experience in the shredder blade industry and is committed to delivering the best possible products and services. We work closely with our customers to understand their needs and requirements, and we are always ready to provide expert guidance and support.

At our company, we take quality seriously. We have a comprehensive quality control system in place, and each blade that leaves our facility undergoes rigorous testing and inspection to ensure it meets our strict standards.

We are committed to delivering products that exceed our customers' expectations and provide long-lasting performance.

Our customer base covers the globe, and we have built strong relationships with clients in North America, Europe, Asia, and beyond.

We understand the importance of timely delivery and responsive customer service, and we are dedicated to providing an exceptional experience to all of our customers.

We are committed to providing our customers with high-quality after-sales service to ensure that your shredder blades perform at their best.

Our after-sales service includes:

|

Product warranty

|

Regular maintenance

|

|

We offer a warranty for all of our shredder blades to ensure that you receive free repair or replacement during the warranty period.

|

We recommend regular maintenance for your shredder blades to keep them in top condition. We provide professional maintenance services, including blade sharpening, cleaning, and lubrication.

|

|

Fast response

|

Customer support

|

|

Fast response: We guarantee a prompt response to your after-sales service request to ensure that your equipment can resume normal operation as soon as possible.

|

Customer support: Our customer support team is always available to provide you with help and advice, ensuring that you can use and maintain your shredder blades with ease.

|

No matter what issues you encounter, we will make every effort to provide you with fast, efficient, and professional after-sales service, giving you peace of mind when using our products.

Q: What materials are commonly used to manufacture shredder blades?

A: Shredder blades are typically made from high-quality tool steels such as

D2, M2, or H13, as well as alloy steels like 4140 or 4340.

Some manufacturers also use carbide and other hard materials to increase blade durability and performance.

Q: How long do shredder blades typically last?

A: The lifespan of shredder blades can vary depending on the materials being shredded, the frequency of use, and other factors. In general, high-quality shredder blades can last anywhere from several months to several years before needing replacement.

Q: How do I know when it's time to replace my shredder blades?

A: Signs that your shredder blades may need replacement include reduced cutting performance, increased noise and vibration during operation, and visible signs of wear or damage on the blades themselves.

Q: Can shredder blades be sharpened or repaired?

A: In some cases, shredder blades can be sharpened or repaired to extend their lifespan. However, this depends on the extent of the damage and the type of blade material.

It's best to consult with a professional blade sharpening or repair service to determine whether your blades can be salvaged.

Q: Are there different types of shredder blades for different applications?

A: Yes, there are many different types of shredder blades available, each designed for specific applications and materials. Some common types of shredder blades include single-shaft, dual-shaft, and quad-shaft blades, as well as various tooth and hook configurations.

Q: How do I choose the right shredder blades for my application?

A: To choose the right shredder blades for your application, you'll need to consider factors such as the type and hardness of the materials being shredded, the required shred size and consistency, and the desired throughput rate. It's also important to consult with a knowledgeable blade manufacturer or supplier who can recommend the best blades for your specific needs.

Q: Can I order custom-made shredder blades?

A: Yes, many blade manufacturers offer custom-made shredder blades to meet specific customer requirements. This may involve designing blades with specific tooth configurations, edge geometries, or other features to optimize performance for a particular application.

Hot Searches