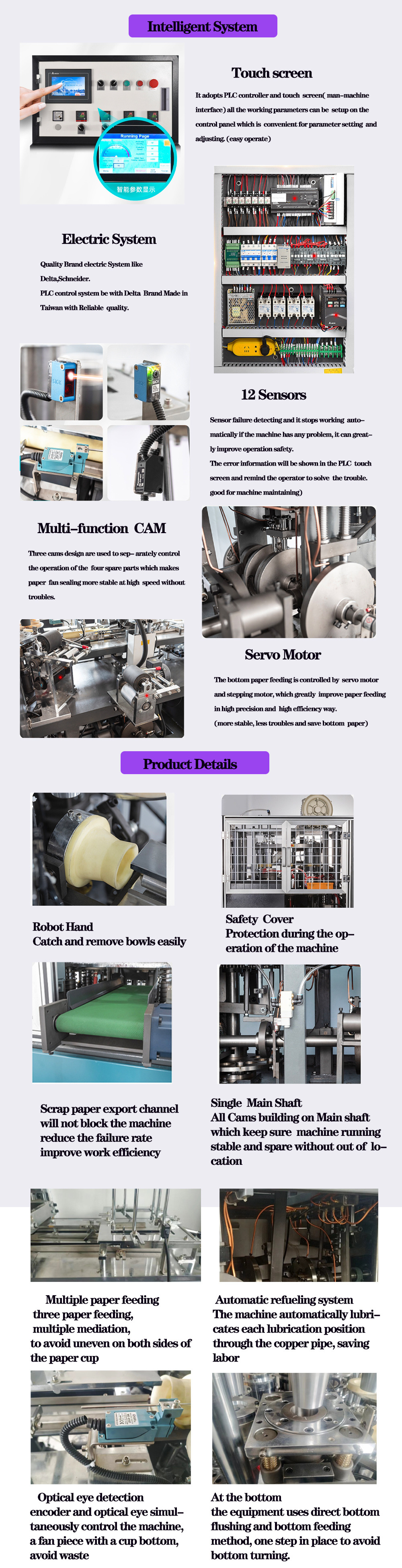

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380 V

-

Power:

-

4.8kw

-

Dimension(L*W*H):

-

2700mm*1300mm*1600mm

-

Weight:

-

1500 kg

-

Cup size:

-

2~16oz

-

working air source:

-

Air Pressure 0.4Mpa

-

cup side welding:

-

ultrasonic heater

-

Rated Speed:

-

75-85pcs/ min

-

raw materical:

-

One or Two side PE coated Paper

-

suitable paper weight:

-

140-350gsm

Quick Details

-

Production Capacity:

-

85 pcs/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380 V

-

Power:

-

4.8kw

-

Dimension(L*W*H):

-

2700mm*1300mm*1600mm

-

Weight:

-

1500 kg

-

Cup size:

-

2~16oz

-

working air source:

-

Air Pressure 0.4Mpa

-

cup side welding:

-

ultrasonic heater

-

Rated Speed:

-

75-85pcs/ min

-

raw materical:

-

One or Two side PE coated Paper

-

suitable paper weight:

-

140-350gsm

Overall frame structure

The overall design is a box structure with welded ribs on the sides. The spray lubrication system is used to reduce wear and dissipate heat effectively, so that the machine has a longer life and more stable operation.

Machine Highlights

1. Different from ordinary paper cup machine, this model adopts full-body square steel structure, which is not more compact and stable under the condition of high-speed operation.

2. The main motor uses a gear reducer motor, using imported bearings NSK. 3. The use of fully automatic closed lubrication system, without the need for manual oil lubrication, can ensure that the machine runs for a long time without interruption at high speed.

4. Parts and components are produced in a standardized manner with strong versatility and good interdependence performance, which is convenient for equipment maintenance.

Mechanical quality assurance

1. Different from ordinary paper cup machine, this model adopts full-body square steel structure, which is not more compact and stable under the condition of high-speed operation.

2. The main motor uses a gear reducer motor, using imported bearings NSK. 3. The use of fully automatic closed lubrication system, without the need for manual oil lubrication, can ensure that the machine runs for a long time without interruption at high speed.

4. Parts and components are produced in a standardized manner with strong versatility and good interdependence performance, which is convenient for equipment maintenance.

Mechanical quality assurance

1. All moving parts on the table are easily accessible, which is convenient for daily cleaning and maintenance.

2. All the moving parts under the countertop are shower-type lubricated and replaced with the specified lubricating

oil every 4 to 6 months.

oil every 4 to 6 months.

|

Specification of paper cup

|

2~16oz

|

|

rated speed

|

75-85pcs/min

|

|

Main motor power

|

8.5kw

|

|

Suitable paper weight

|

140-350gsm

|

|

Raw Material

|

One or Two side PE coated Paper( Popular for Hot and Cold drink Cups)

|

|

Total Weight

|

GW/NW:1800KGS/1700KGS

|

|

Pack Size(L"W'H)

|

2200* 1400* 1900mm( Wooden Box Packing Size) 1000*750* 2100MM( Counting Machine Packing Size)

|

|

Working Air Source

|

Air pressure:0.4Mpa;

AirOut-put:0.6m3/minute Need to buy Air Compressor( by user) |

|

Cup Side Welding

|

Cup Side Welding

|

|

Cup Bottom Heating

|

1side PE paper by heater knurling: 2side PE paper by cool device(circle water)knurling.

|

|

Cup Bottom Knurling

|

Heater Knurling (if use single PE coated paper)

|

Hot Searches