- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LIROB

-

Weight (KG):

-

161

-

Voltage:

-

220V

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

1468mm

-

Usage:

-

Automatic TIG Welding

-

Product name:

-

welding robot station

-

Application:

-

Metal Welding

-

package:

-

polywooden case

Quick Details

-

Applicable Industries:

-

metal welding

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

China

-

Brand Name:

-

LIROB

-

Weight (KG):

-

161

-

Voltage:

-

220V

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

1468mm

-

Usage:

-

Automatic TIG Welding

-

Product name:

-

welding robot station

-

Application:

-

Metal Welding

-

package:

-

polywooden case

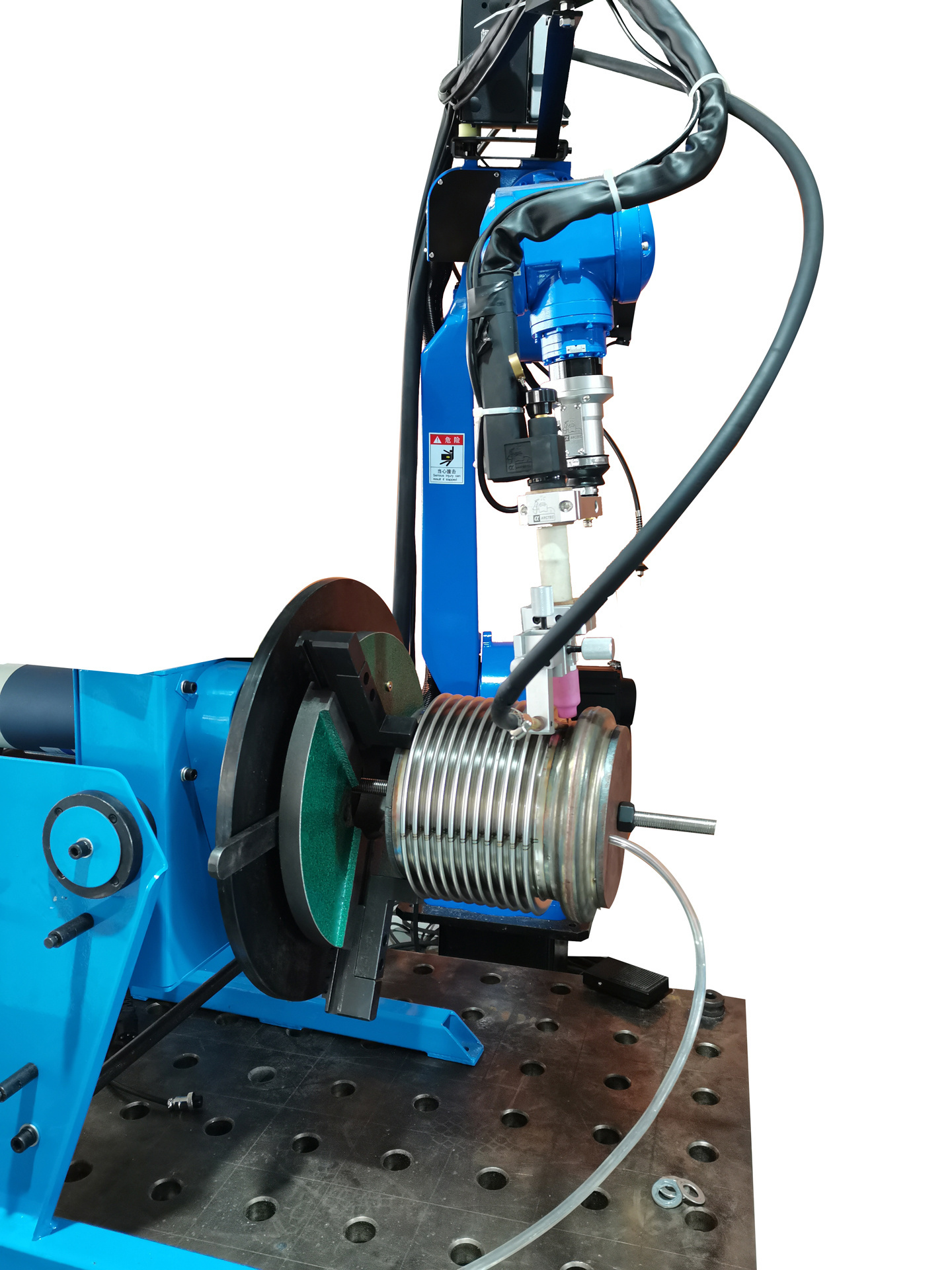

Products Description

|

Product Name:

|

OEM Automatic Stainless Steel Aluminum Pipe TIG Argon Arc Welding Robot Arm Welding Machine

|

|

|

|

|||

|

Advantages of robotic welding:

|

1. Increase production efficiency.

2. Improve product quality.

3. Lower requirements for workers’ operating techniques.

4. Reduceproduction costs.

5. Shorten the cycle of product modification and updating and the corresponding investment in equipment.

6. Improve the working conditions of workers.

7. Enhance corporate image.

|

|

|

|

|||

|

LJ1468 Features:

|

1. Multi-Functions: Welding, Handing, Stacking.

2. The teaching device is thinner and lighter. 3. Low noise. 4. Easy too maintain. 5. High cost performance. 6.With complete arc welding function package, suitable for various applications: Basic arc welding, high pressure seeking, arc tracking, point laser seeking, laser tracking, multi-layer and multi-channel welding, additional axis coordination. |

|

|

|

|||

|

WSME-315R Features:

|

Excellent welding performance

1. Simple arc starting, stable arc, high welding quality. 2. In the AC argon arc welding state, there are a variety of waveforms to choose: standard square wave, sine wave, mixed wave, etc. 3. By adjusting the peak current, base current, pulse frequency, duty cycle and AC current, AC frequency and cleaning ratio, the required weld depth and width and the uniformity of surface ripple can be obtained to extend the life of tungsten electrode, especially suitable for automatic welding and robot welding. 4. Up to 10 sets of user-defined standard parameters can be stored for easy call. 5. Full digital high-precision wire feeding control system, two drive two slave encoder full digital control wire feeding device, even if the power supply voltage, wire feeding resistance and other external factors change, still can ensure the stability of wire feeding. 6. It is suitable for sheet welding of stainless steel, carbon steel, copper, titanium, aluminum and their alloy. Additional Robotic Features 1. Open digital communication mode, the robot can control the welding machine current, wire feeding speed, arc starting delay wirefeeding time, arc extinguishing back wire drawing length and other process parameters. 2. Digital communication interfaces such as DEVICENET, CAN, CANopen, 485, EtherneTip and other international standards CAN realize seamless integration with different brands of robots. 3. Integrated analog communication interface, current, wire feeding speed, arc, point wire feeding and other functions of remote control robot, plug and play. |

|

|

|

|||

Product Parameters

|

Items

|

|

Parameters

|

|

|

Model

|

|

LJ1468

|

|

|

Controller

|

|

CS9

|

|

|

Controlled Axis

|

|

6

|

|

|

Max. Payload

|

|

10kg

|

|

|

Repeated Positioning Accuracy

|

|

±0.08mm

|

|

|

Working Enviroment

|

|

0~40℃, 75%RH, 90%RH short period.

|

|

|

Mechanical Weight

|

|

161kg

|

|

|

Reach

|

|

1468mm

|

|

|

Motion Range (°)

|

J1Axis

|

±170°

|

|

|

|

J2Axis

|

-90°- +80°

|

|

|

|

J3Axis

|

-90°- +85°

|

|

|

|

J4Axis

|

±180°

|

|

|

|

J5Axis

|

-105°- +130°

|

|

|

|

J6Axis

|

±350°

|

|

|

Max. Speed (°/s)

|

J1Axis

|

190°/s

|

|

|

|

J2Axis

|

140°/s

|

|

|

|

J3Axis

|

140°/s

|

|

|

|

J4Axis

|

220°/s

|

|

|

|

J5Axis

|

150°/s

|

|

|

|

J6Axis

|

320°/s

|

|

|

Installation Method

|

|

Grounded or Inversion installing

|

|

|

Power

|

|

220V ~1PH,50HZ/60HZ

|

|

|

Controller Weight

|

|

55kg

|

|

|

Welding Power Source

|

WSME-315R

|

|

Rated supply voltage

|

3PH 380V±10%, 50Hz

|

|

Rated input capacity

|

13KVA

|

|

Rated input current

|

22.4A

|

|

Rated output current

|

315A

|

|

Duty Cycle

|

60%

|

|

Rated output voltage

|

MMA: 40V

|

|

|

TIG: 66V

|

|

Output Current/Voltage

|

TIG(DC): 5A/10.2V-315A/22.6V

|

|

|

TIG(AC): 10A/10.4V-315A/22.6V

|

|

Output Voltage range

|

STICK: 5A/20.2V-315A/33V

|

|

Torch cooling

|

Air/Water

|

|

Insulation Grade

|

H

|

|

Protection Grade

|

IP23

|

|

Dimension

|

655*325*560mm

|

|

Weight

|

57kgs

|

More Product

Product Applications

Hot Searches