- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Varies Depending

-

Dimension(L*W*H):

-

Capacity

-

Weight:

-

450 KG

-

Machinery Capacity:

-

25000L/250HL

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SUS304/SUS316/red Copper

-

Function:

-

Brewing Beer Brewing Equipment

-

Control system:

-

Temperature

-

Interior Finish:

-

Completely acid washing and passivation

-

Inside polishing:

-

0.2~0.4 μm without dead corner

-

Welding:

-

100% TIG welding with pure argon gas shield

-

Interior Shell:

-

SUS304 full welded; TH=3mm

-

Exterior Shell:

-

SUS304 full welded or red copper half welded; TH=2mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tiantai

-

Voltage:

-

380V/3PH/50Hz

-

Power:

-

Varies Depending

-

Dimension(L*W*H):

-

Capacity

-

Weight:

-

450 KG

-

Machinery Capacity:

-

25000L/250HL

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SUS304/SUS316/red Copper

-

Function:

-

Brewing Beer Brewing Equipment

-

Control system:

-

Temperature

-

Interior Finish:

-

Completely acid washing and passivation

-

Inside polishing:

-

0.2~0.4 μm without dead corner

-

Welding:

-

100% TIG welding with pure argon gas shield

-

Interior Shell:

-

SUS304 full welded; TH=3mm

-

Exterior Shell:

-

SUS304 full welded or red copper half welded; TH=2mm

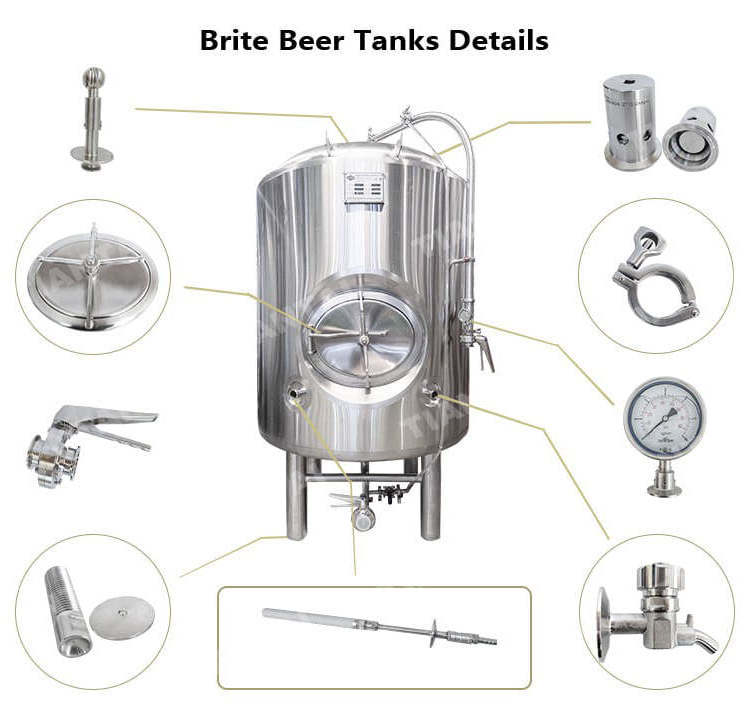

Part 1

General Description of 25 000L/ 25 0HL Bright Beer Tank

------ Quality Design for Craft Brewing

25 000L 25 0HL customized stainless steel cooling jacketed pressured beer bright tank is specially designed for commercial brewery brewing system. It applies for b eer maturation , conditioning , serving , or filtered beer receiving. The tank also called BBT, it has dished top and bottom , cooling device which can easily control the fermentation temperature. A rotating cleaning ball is installed inside the tank top, which is connected with the CIP cleaning system to clean the inner wall of the tank at 360 degrees, ensuring hygiene and safety in production.

--With ISO TUV SGS, the product meets GB/CE/PED/ASME standard

--Local service in EUROPE, AUSTRALIA, etc

-- 5 Years Warranty for tanks

--0 trade risk verified by more than 1100 breweries

--Made of Stainless steel 304, TIG welded by automatic welding machine.

--Interior polished to 0.2-0.4 μm to ensure no dead corner for bacteria and full sanitary.

--Triangle-Arranged holes on glycol jacket for higher cooling efficiency.

--All gaskets made of EPDM which have more durable use time.

--Fermentation pressure adjustable, suitable for maturation and bottling .

--Completely SUS304 legs with strengthening braces to prevent tank deformation.

-- Heavy duty foot pads with adjustable ability, apply to uneven or slope ground.

|

Design Basis Tank Working Pressure: 2bar/30psi Manway: On side Insulation: TH=80mm with low thermal conductivity PU |

Energy Consumption

Cooling:35% Glycol liquid -5℃ |

|

Dimension

Dimension: Φ2400x8900mm (Customizable) Dished bottom |

Controlling

Temperature control |

|

Function: |

Beer maturation/conditioning/serving/filtered beer receiving |

|

Tank Capacity: |

25 000 L (+25% Head space minimum) |

|

Dimension: |

Φ2400x8900mm (Customize) |

|

Interior Shell: |

SUS304 full welded; TH=3mm |

|

Exterior Shell: |

SUS304 full welded; TH=2mm |

|

Welding |

100% TIG welding with pure argon gas shield |

|

Interior Finish: |

Sanitary 2B finish, Pickled and Passivated; (8K Mirror finish optional) |

|

Exterior Finish: |

Oil brushed finish(2B, 8K Mirror finish optional) |

|

Polishing |

Interior full polished to 0.2~0.4 μm without dead corner |

|

Insulation: |

TH=80mm with low thermal conductivity PU |

|

Cooling: |

35% Glycol liquid -5℃ |

|

Cooling Jacket: |

Dimple plate on bottom and side wall, welded without over burning |

|

Jacket test |

by water and gas, 5bar/75psi for 1hour, 3.5bar/52psi for 48 hours |

|

Jacket Working Pressure: |

< 2bar/30psi |

|

Tank leakage test |

by water and gas, 4bar/60psi for 1hour, 2.5bar/37.5psi for 48 hours |

|

Tank Working Pressure: |

2bar/30psi |

|

Dished Top: |

Dished top full polished |

|

Dished bottom: |

W ith conical insulation |

|

Manway: |

Sanitary side mounted oval manhole with pressured door ( top mounted available) |

|

CIP Ball: |

Top mounted double clamp 360° rotary CIP spraying ball and port, 1pcs |

|

CIP arm: |

with four-way connection and butterfly valve |

|

Mechanical safe valve PVRV: |

2bar/30psi on top (1bar/15psi available) |

|

Sampling Valve: |

Full sanitary sampling valve with EPDM seal |

|

Hydraulic shock pressure gauge: |

on CIP arm (Diaphragm type for optional) |

|

Discharge arm: |

With butterfly valve, Removable and easy to clean |

|

Thermowell : |

Sanitary welded thermowell for high accuracy temperature sensor 1pcs |

|

Carbonation: |

Carbonation port with CO2 dissolved stone 0.22um |

|

Glycol water port: |

In/out port on side wall and cone, Thick wall pipe thread (Top or bottom design available) |

|

Legs: |

4pcs completely SUS304 legs with braces, heavy duty foot pad with up-down and slop adjustable |

|

Accessories: |

Complete valves, fittings and all parts, Tri clamp/DIN Union available |

|

Special request |

Pressure adjustable bunging valve 0.2-2.2bar ; Sanitary level tube and valves ; |

PART 2

Learn More about 25 000L/ 25 0HL Bright Beer Tank

------ Customized Details for Better Brewing