- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Custom

-

Brand Name:

-

KAIAO

-

Material:

-

Customers' Requirement

-

Process:

-

CNC Machining

-

Product name:

-

CNC machining brass parts

-

Surface treatment:

-

Customer's Request

-

Service:

-

Customized OEM

-

Equipment:

-

Milling Machine

-

Application:

-

Industrial Equipment

-

Keyword:

-

custom brass parts

-

OEM/ODM:

-

OEM ODM Non-standard Processing

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Plastic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Custom

-

Brand Name:

-

KAIAO

-

Material:

-

Customers' Requirement

-

Process:

-

CNC Machining

-

Product name:

-

CNC machining brass parts

-

Surface treatment:

-

Customer's Request

-

Service:

-

Customized OEM

-

Equipment:

-

Milling Machine

-

Application:

-

Industrial Equipment

-

Keyword:

-

custom brass parts

-

OEM/ODM:

-

OEM ODM Non-standard Processing

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

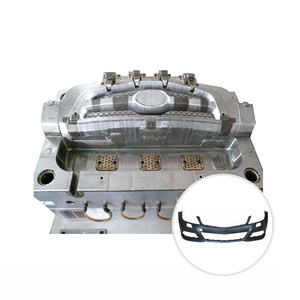

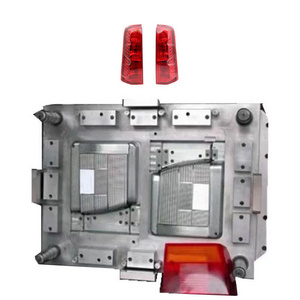

KAIAO Quality Car Front and Rear Bumper Mould Supplier Factory Customized Plastic Reaction Injection Molding Service

Manufacturing Technique

Low-Volume Manufacturing Quality And Efficiency

Low-volume manufacturing is a process of pre-mass production between rapid prototyping and mass production of a pre-mass production.

Most engineers and product designers will choose low-volume manufacturing to get the parts for marketing. The reason is that low-volume manufacturing can shorten the production cycle and let you reduce time in product development and cost. It also allows you to quickly respond to marketing requirements and iterate on your product features faster.

For low-volume manufacturing, you may be more concerned about the quality and precision of the product. However, KAIAO uses strict tolerance standards, the same materials, and quality inspection as mass production.

Most engineers and product designers will choose low-volume manufacturing to get the parts for marketing. The reason is that low-volume manufacturing can shorten the production cycle and let you reduce time in product development and cost. It also allows you to quickly respond to marketing requirements and iterate on your product features faster.

For low-volume manufacturing, you may be more concerned about the quality and precision of the product. However, KAIAO uses strict tolerance standards, the same materials, and quality inspection as mass production.

|

Low-Volume Manufacturing

|

|

|

|

|

1 It is typically faster which allows companies to get their product to the market quickly.

2 It is a method that serves all industries to manufacture plastic parts with injection techniques.

3 It can help to minimize the molding time to produce your products faster ,fulfill pre-mass production with real material.or produce end products at low quantities.

|

|

|

|

We routinely work with all conventional metals including

copper, brass, stainless and mild steel, magnesium, and aluminum.

We also have a robust supply chain with thousands of commercial plastic resins, including

transparent plastics, engineering- and

medical-grade plastics, glass-filled plastics, and more. |

|

|

What are the advantage of Low-volume manufacturing?

|

Low cost, flexible, beforehand, and efficient.

The product quality reaches the industrial level, which can completely reach the quality requirements of customers.

|

|

|

|

To help our clients get the ideal look and feel for their products, we offer a wide range of different surface finishes. Some of our most popular finishing services include

anodizing, painting, color matching, pad printing, sanding and polishing, vapor

polishing and blasting. |

|

How To Start Low-Volume Manufacturing

The low-volume manufacturing process is suitable for 1-1000 parts production. If you already have a specific product model, you only need to send us the detailed size and manufacturing requirements (including material, surface finishes, etc.) Time to contact you and develop an efficient production plan for fast delivery. If you don’t have any product model, you can learn about our rapid prototyping service or tell us your idea and start your small batch production.

We provide a variety of efficient processing technologies for low-volume manufacturing. You can choose the corresponding process according to your materials, tolerance requirements, and surface finishes.

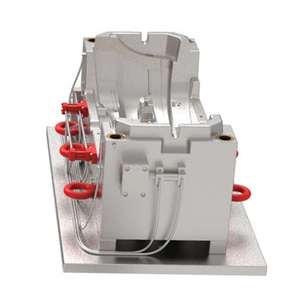

CNC machining and reaction injection molding are our standard processes with low-volume manufacturing. The following section can view the process introduction about KAIAO’s low-volume manufacturing. You can also ask us for a free quote; We will provide you with an excellent cost-effective production plan.

We provide a variety of efficient processing technologies for low-volume manufacturing. You can choose the corresponding process according to your materials, tolerance requirements, and surface finishes.

CNC machining and reaction injection molding are our standard processes with low-volume manufacturing. The following section can view the process introduction about KAIAO’s low-volume manufacturing. You can also ask us for a free quote; We will provide you with an excellent cost-effective production plan.

Plastic Injection Molding

Plastic injection molding is ideal for making thousands of part copies with a wide range of plastic material.

CNC Machining

Using our 3, 4, and 5-axis CNC machining centers, We provide CNC milled and turned parts available.

Vacuum Casting

Vacuum casting is ideal for making up to 20 copies of a master pattern for plastic injection molded parts.

Hot Searches