- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MK

-

Color:

-

Black/blue/gray/customizable

-

Dimensional tolerance:

-

<±5mm

-

Technics:

-

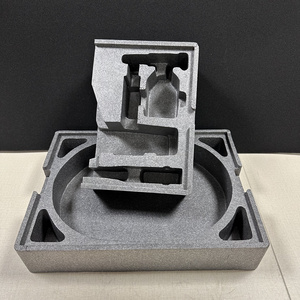

Mold integral foam molding

-

Application:

-

Cold-chain transportation,Logistics transportation,

-

Feature:

-

Eco-friendly,Waterproof,Non-toxic,Durable,Recyclable

-

Certificate:

-

ISO9001/ROHS/Intertek/TUV/Bureau Veritas/SABER/PVOC

-

Function:

-

Front Collision protecting,Transportation Protective Packaging

Quick Details

-

Material:

-

Imported foamed polypropylene

-

Type:

-

expanded polypropylene

-

Place of Origin:

-

Imported foamed polypropylene

-

Brand Name:

-

MK

-

Color:

-

Black/blue/gray/customizable

-

Dimensional tolerance:

-

<±5mm

-

Technics:

-

Mold integral foam molding

-

Application:

-

Cold-chain transportation,Logistics transportation,

-

Feature:

-

Eco-friendly,Waterproof,Non-toxic,Durable,Recyclable

-

Certificate:

-

ISO9001/ROHS/Intertek/TUV/Bureau Veritas/SABER/PVOC

-

Function:

-

Front Collision protecting,Transportation Protective Packaging

Wholesale Heavy Load Light-weight Expanded Polypropylene Pipes EPP Ball Valves Insulation Accessories Parts

Wholesale Heavy Load Light-weight Expanded Polypropylene Pipes EPP Ball Valves Insulation Accessories Parts

WHY USE PARTICLE FOAM IN AUTOMOBILES?

Particle foams have a wide range of positive properties, especially for the automotive sector, which no other material in combination can fulfil:

1) high structural strength at very low weight

2) great freedom of design

2) very good energy absorption

4) high resilience (EPP)

5) fully recyclable

6) good chemical resistance (EPP)

7) good sound insulation/sound absorption

8) excellent thermal insulation (e.g. for e-mobility)

Applications of EPP in the Automotive Industry:

EPP is extensively used by automotive manufacturers because of its performance benefits with regard to being able to absorb repeated shocks, its light weight, its enhanced functionality, its durability and its recyclability. These properties make it an ideal choice for the automotive industry to manufacture various parts such as seat cores, bumper cores, sun visors, impact modifier blocks, tool and jack trays, load floors, dashboard panel pads, door panels, side impact protection panels, fenders, battery covers, head rests, etc. out of EPP.

Advantages:

1 ) lightweight, environmentally friendly, degradable and recyclable, strong and durable, and good sealing performance;

2 ) Rigidity is 7 times that of ordinary foam, good stability, not easy to be deformed, good anti-falling and compressive cushioning performance (15 times high-density EPP compressive resistance, normal service life up to 3-5 years;

3 ) Dirt-resistant, easy to clean, long-lasting heat preservation and freshness (imported EPP, thermal conductivity of 0.021w/(M*K), EPS ordinary foam box is 0.042w/(M*K), and its heat loss rate is twice as fast as EPP incubator ) Food grade EPP;

Application : Catering and cold-chain transportation,Logistics transportation,Camping, Fishing, Traveling, Picnic takeaway, Transportion for fruits,vagtables, seafood, lunch etc, Seafood shipping,Pharmaceuticals,Home storage.