- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

3100x2150x1150mm

-

Weight (KG):

-

16000

-

After-sales Service Provided:

-

No overseas service provided

-

Name:

-

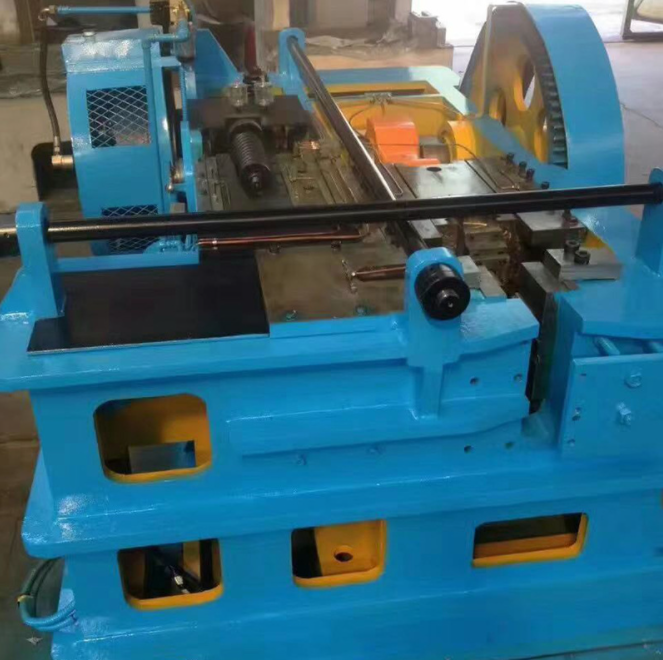

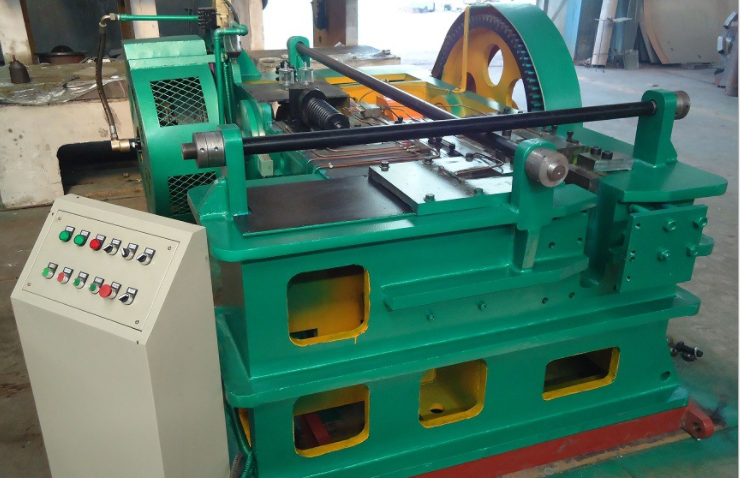

Forging press

-

power:

-

11kw

-

COLOR:

-

green,blue ,white or made to order

-

Application in:

-

forgings

-

Model:

-

DH125

-

Nominal capacity:

-

125ton

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LPMIE

-

Machine Type:

-

forging machine

-

Voltage:

-

220V/380V/440V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

3100x2150x1150mm

-

Weight (KG):

-

16000

-

After-sales Service Provided:

-

No overseas service provided

-

Name:

-

Forging press

-

power:

-

11kw

-

COLOR:

-

green,blue ,white or made to order

-

Application in:

-

forgings

-

Model:

-

DH125

-

Nominal capacity:

-

125ton

-

After Warranty Service:

-

Video technical support

LPH10 Series Horizontal Forging Machine

Description:

Our LPH10 series Horizontal forging machine is an upsetting Forging Machinery for metal long rod and pipe’s ends fixed station forming. It can complete the upsetting, punching, trimming, extrusion, cutting,shrinking, bending pipe work, so widely used in forging standard parts, hardware tools, auto parts forming process.

Characteristics:

1. The fuselage is made of integral cast steel, with good rigidity, high precision and durability.

2. Pneumatic clutch device is adopted.

3. Steel gear, wear-resistant, not easy to break teeth and damage, so as to reduce the maintenance cost for users.

4. All bushings and bearing shells on the machine are made of tin bronze, with little wear, no damage to the crankshaft, and the service life is more than three times that of ordinary bearing shells.

5. After the whole body quenching and tempering heat treatment, the tensile strength, internal stress and impact force of the crankshaft meet the requirements of national standards.

Main Parameters:

|

Sequence |

Item |

unit |

DH125 |

|

1 |

norminal force |

kN |

1250 |

|

2 |

forge slider block stroke |

mm |

130 |

|

3 |

Clamp slider block stroke |

mm |

70 |

|

4 |

Strokes per min |

mm |

60 |

|

5 |

Max die installation height |

times/min |

320 |

|

6 |

Board plate thickness |

mm |

100 |

|

7 |

Slider bottom size(up to down X L/R) |

mm |

360×250 |

|

8 |

Clamp mold size ( L×W×H ) mm |

mm |

300×195×350 |

|

9 |

Work hole size ( W×Depth ) mm |

mm |

100 × 350 |

|

10 |

Motor power kw |

mm |

11 |

|

11 |

dimension |

kw |

3100 × 2150 × 1150 |

|

12 |

weight |

kg |

9000 |