- Product Details

- {{item.text}}

Quick Details

-

Power:

-

20-200KW

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

300 KG

-

Core Components:

-

Tanks

-

Product Name:

-

2000L Craft Beer Equipment 20HL Brewery Project 20BBL Brewing System

-

Keywords:

-

Beer Brewing Equipment

-

Function:

-

Brewing beer

-

Capacity:

-

100L -35000L

-

Material:

-

Stainless Steel 304/316

-

Thickness of Tanks:

-

Inner 3mm/ Outer 2mm

-

Control system:

-

PIC Control or PID control

-

Polish:

-

0.4-0.6um/Mirror Polished

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chenma

-

Voltage:

-

380V

-

Power:

-

20-200KW

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

300 KG

-

Core Components:

-

Tanks

-

Product Name:

-

2000L Craft Beer Equipment 20HL Brewery Project 20BBL Brewing System

-

Keywords:

-

Beer Brewing Equipment

-

Function:

-

Brewing beer

-

Capacity:

-

100L -35000L

-

Material:

-

Stainless Steel 304/316

-

Thickness of Tanks:

-

Inner 3mm/ Outer 2mm

-

Control system:

-

PIC Control or PID control

-

Polish:

-

0.4-0.6um/Mirror Polished

Product Description

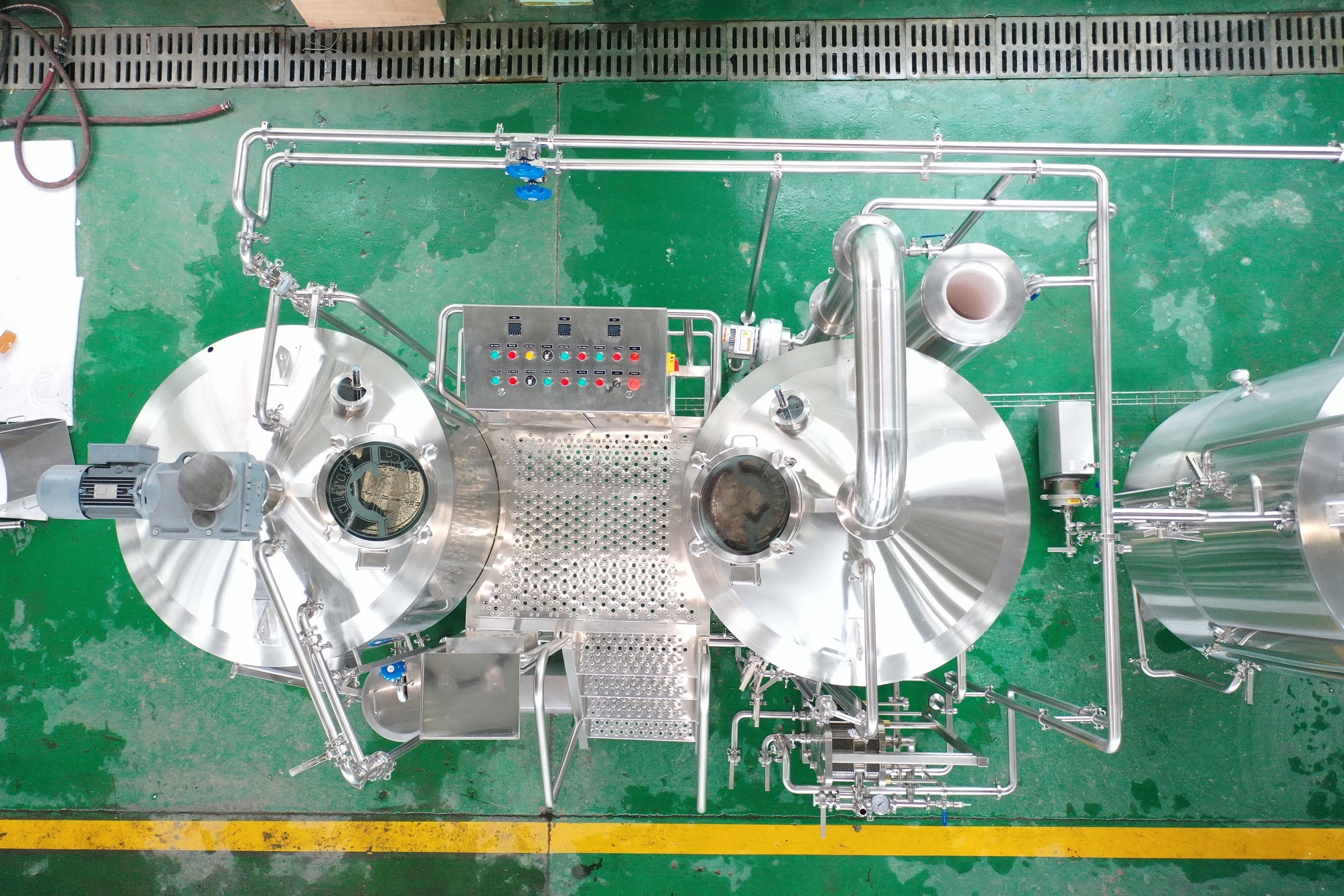

2000L Craft Beer Equipment 20HL Brewery Project 20BBL Brewing System for Beer Production

A complete brewery includes malting miller system, brewhouse system, fermentation system, cooling system, heating system, CIP system, control system and packaging system.

Brewhouse has 2 vessels, 3 vessels, 4 vessels, 2 vessles brewhouse is mash lauter tun, kettle whirlpool tun, 3 vessels brewhouse is mash tun, latuer tun, kettle whirlpool tun, or mash kettle tun, lauter tun, whirlpool tun, 4 vessles brewhouse is mash tun, lauter tun, kettle boiling kettle tun, whirlpool tun. Matched hop filter, plate heat exchanger ect.

Racking arm

Carbonation stone

Sample vlave

Spunding valve

Welding

Polishing

A complete brewery includes malting miller system, brewhouse system, fermentation system, cooling system, heating system, CIP system, control system and packaging system.

The beer fermentation tanks are used for fermenting beer, conical fermentation tanks can withstand 3bar pressure, has a cooling jacket, polyurethane insulation, is equipped with upper and side manholes, spunding valve, sample valve, racking arm, pressure gauge, CIP arm, PVRV, carbonation stone, spray ball, butterfly valves ect .

Specification

|

Item

|

Specifications

|

|

Malt miller

|

Stainless steel, two rollers

|

|

Mash / lauter tun

|

Rake with ABB motor, with VFD, false bottom, discharged spent door, spraying grain ring, steam heating

|

|

Kettle whirlpool tun

|

steam, electric, or direct fire heating

|

|

Wort pump

|

Centrifugal pump with variable frequency drvice

|

|

Hot water tank

|

Centrifugal pump with variable frequency

|

|

Hot wort pump

|

Centrifugal pump

|

|

Hop filter

|

Filter hops

|

|

Heat exchanger

|

Plate heat exchanger, single stage or double stages, NANHUA

|

|

Fermenters

|

3bar pressure, cooling jacket, insulation, rack arm, spunding valve, pressure gauge, sample valve, spray ball

|

|

Hose

|

PEDM

|

|

Glycol chiller

|

KANSAN, 404A

|

|

Glycol water tank

|

Insulation

|

|

Glycol water pump

|

Centrifugal pump

|

|

CIP trolley

|

Alkali tank with electric heating, acid tank, washing pump, control box, trolley

|

|

Control system

|

PLC control with Siemens system, PID control with buttons and control instrument

|

|

Accessories

|

Thermometer, Sample valve, Breather, Level gauge, Wine inlet /outlet, Drain outlet

|

Packing & Delivery

Packaging & Shipping

1. All equipment is packaged to meet sea shipping requirements.

2. Chenma has two packaging forms: iron frame packaging and wooden packaging, which are packed according to the transportation terms.

3. Chenma supplies the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1. All equipment is packaged to meet sea shipping requirements.

2. Chenma has two packaging forms: iron frame packaging and wooden packaging, which are packed according to the transportation terms.

3. Chenma supplies the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Chenma Service

Chenma provides 7*24 hours pre-sales and after-sales services

1. Pre-sales

1). Chenma provides free solutions for your project

2). Chenma will provide drawings for your reference according to your requirements.

3). Chenma provides free floor plan according to the size of your factory.

4). Chenma provides a pre-container plan for your order

5). Chenma supports customizastion service

2. After-sales

1). Chenma provides free online installation for your order

2). Chenma can send engineers to your site for installation

3). The warranty period of Chenma’s main equipment is 3 years, and the warranty period of auxiliary parts is 1 year.

4). Chenma provides lifetime maintenance services

5). Chenma provides customers with on-site training services

1. Pre-sales

1). Chenma provides free solutions for your project

2). Chenma will provide drawings for your reference according to your requirements.

3). Chenma provides free floor plan according to the size of your factory.

4). Chenma provides a pre-container plan for your order

5). Chenma supports customizastion service

2. After-sales

1). Chenma provides free online installation for your order

2). Chenma can send engineers to your site for installation

3). The warranty period of Chenma’s main equipment is 3 years, and the warranty period of auxiliary parts is 1 year.

4). Chenma provides lifetime maintenance services

5). Chenma provides customers with on-site training services

Hot Searches