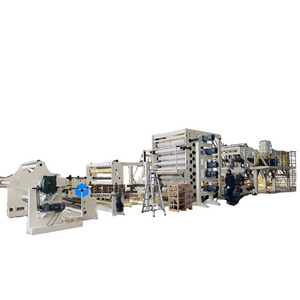

The equipment features advanced technology and high automation control, enabling efficient production

and ensuring consistency and stability by minimizing human factors.

and ensuring consistency and stability by minimizing human factors.

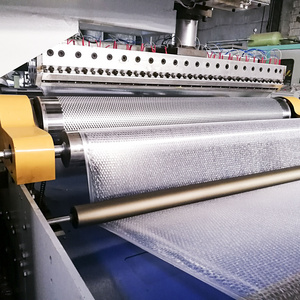

Strong flexibility:

The equipment can produce both regular polyethylene bubble film and composite polyethylene bubble film, meeting the diverse needs of different customers. Moreover, it can adjust production parameters such as bubble size and thickness to accommodate various specifications and requirements.

The equipment can produce both regular polyethylene bubble film and composite polyethylene bubble film, meeting the diverse needs of different customers. Moreover, it can adjust production parameters such as bubble size and thickness to accommodate various specifications and requirements.

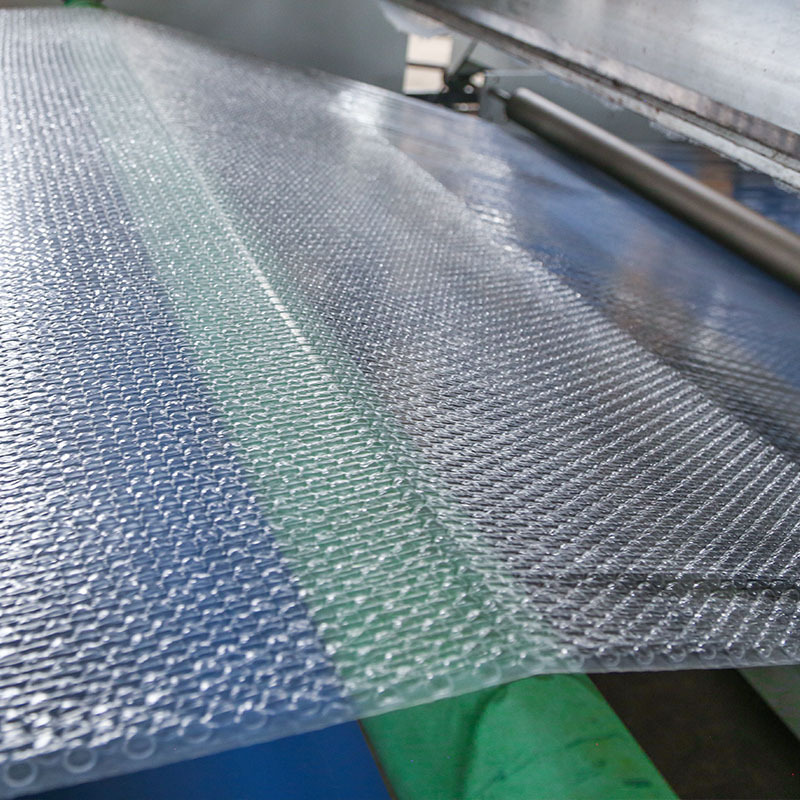

Stable product quality:

High-quality materials and advanced production processes are used to ensure stable and reliable quality of the produced bubble film. The automated control system monitors the production process to ensure that the product quality meets standards.

High-quality materials and advanced production processes are used to ensure stable and reliable quality of the produced bubble film. The automated control system monitors the production process to ensure that the product quality meets standards.

Durability:

The equipment is constructed with high-quality materials, sturdy and durable, with a long service life. Precision manufacturing processes and reliable components guarantee stable operation and efficient production.

The equipment is constructed with high-quality materials, sturdy and durable, with a long service life. Precision manufacturing processes and reliable components guarantee stable operation and efficient production.

Ease of operation:

The equipment has a user-friendly interface, making it easy to operate and maintain. Clear operation instructions and training courses are provided to enable operators to quickly master the operation skills and ensure the equipment operates smoothly.

Energy-saving and environmentally friendly:

The equipment adopts advanced energy-saving technology and environmentally friendly materials to reduce energy consumption and minimize environmental impact. The production process reduces emissions of wastewater, exhaust gases, and waste residue, aligning with modern environmental requirements

The equipment has a user-friendly interface, making it easy to operate and maintain. Clear operation instructions and training courses are provided to enable operators to quickly master the operation skills and ensure the equipment operates smoothly.

Energy-saving and environmentally friendly:

The equipment adopts advanced energy-saving technology and environmentally friendly materials to reduce energy consumption and minimize environmental impact. The production process reduces emissions of wastewater, exhaust gases, and waste residue, aligning with modern environmental requirements