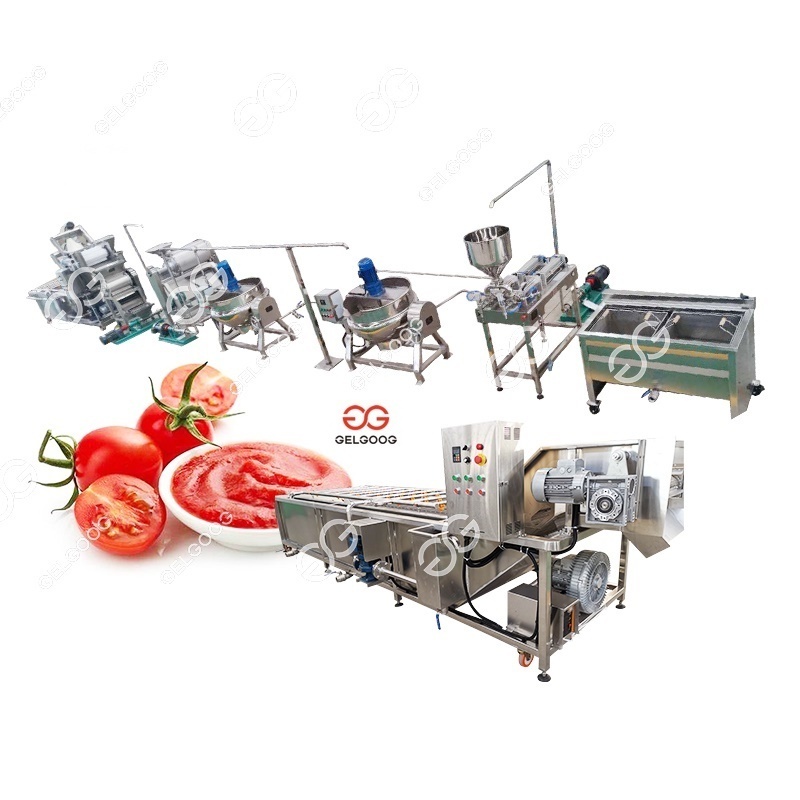

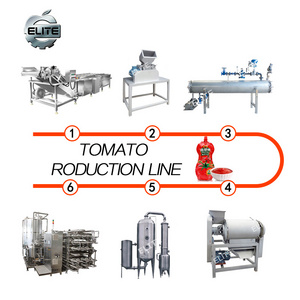

Tomato sauce small production line

can produce from fresh tomato to different kinds of final product. The most popular is tomato paste processing line, produce from fresh tomato to tomato paste with aseptic bag in drum. That mainly includes: fresh tomato receiving system, washing system, sorting system, extracting system, concentrating system, sterilizing system, and aseptic filling system. Then can get the tomato paste with aseptic bag in drum. And the tomato paste in aseptic bag in drum can be further produced to tomato ketchup, sauces, juice and filled in sachet, stand-up pouch, metal can, PP container, bottle, gable top, etc.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

900 KG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380v

-

Product name:

-

Tomato Sauce Making Machine Price Maker Concentrated Tomato Paste Line

-

Material:

-

Stainless Steel

-

Function:

-

Multifunctional

-

Feature:

-

High Efficiency

-

Applicable Industries:

-

Farms

Quick Details

-

Machinery Capacity:

-

200-800kg/h

-

Brand Name:

-

GELGOOG

-

Model Number:

-

GG-500

-

Weight:

-

900 KG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380v

-

Product name:

-

Tomato Sauce Making Machine Price Maker Concentrated Tomato Paste Line

-

Material:

-

Stainless Steel

-

Function:

-

Multifunctional

-

Feature:

-

High Efficiency

-

Applicable Industries:

-

Farms

Products Description

Automatic Concentration Tomato Sauce Making Machine Price Maker Concentrated Tomato Paste Line

Gelgoog Food Processing Machinery Company, a professional tomato processing line manufacturer and exporter in China. Which can provide turnkey solution and technical support for tomato processing line with different kinds of end products from tomato.

Important reminder:

1,The technical parameters are for reference only.

2,The product quotation is for reference only, It is based on the actual purchased model and configuration.

3,For more information, please call or consult customer service.

Product Paramenters

|

Processing Capacity(KG/H) (fresh fruit)

|

60

|

150

|

250

|

500

|

750

|

1000

|

1250

|

1500

|

|||||||

|

Water Consumption (t/h)

|

7

|

13

|

22

|

44

|

66

|

88

|

110

|

132

|

|||||||

|

Power(kw)

|

84

|

152

|

412

|

636

|

955

|

1292

|

1411

|

1558

|

|||||||

|

Steam Consumption(t/h)

|

1.7

|

3.9

|

5.2

|

9.1

|

15.1

|

20.2

|

24.6

|

29.2

|

|||||||

|

Compressed Air Consumption (t/h)

|

66.2

|

66.2

|

66.2

|

72.2

|

72.2

|

72.2

|

72.2

|

72.2

|

|||||||

|

Cooling Water Consumption (t/h)

|

125

|

317

|

407

|

585

|

825

|

1075

|

1410

|

1630

|

|||||||

|

Advantages:

|

The tomato processing line from Gelgoog machinery company is running with high effective, water saving, high extracting rate, safety quality control for final product, safety control for operators, etc.

|

|

|

|

|

|

|

|

|||||||

Recommend Products

Details Images

Certifications

Exhibition

Our Factory

Tina Name Card

Hot Searches