The double stage hammer mill crusher can easily crush high-humidity materials such as coal gangue, shale, coal slag and other materials. Used as gangue and coal slag as additive and internal fuel for brick factory; using gangue and shale to produce standard brick and hollow brick.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

According different models to

-

Warranty:

-

12 Months, 12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Mining equipment double stage crusher for wet materials

-

Application:

-

Mainly for coal gangue, masonry, shale and construction waste, etc

-

Installation:

-

Engineers Guide

-

The Machines classification:

-

Two-stage crusher, double stage crusher

-

Keywords:

-

Two-stage crusher,Two-stage grinder, Doubel grade crusher

-

After sale service:

-

Life-long Service

-

Spare Parts Supply:

-

Life Long Provide

-

Feeding size:

-

According to different models

-

Local Service Location:

-

Ukraine

-

Certification:

-

ISO9001:2015

Quick Details

-

Capacity(t/h):

-

According to different models

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HENGCHANG

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

According different models to

-

Warranty:

-

12 Months, 12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Mining equipment double stage crusher for wet materials

-

Application:

-

Mainly for coal gangue, masonry, shale and construction waste, etc

-

Installation:

-

Engineers Guide

-

The Machines classification:

-

Two-stage crusher, double stage crusher

-

Keywords:

-

Two-stage crusher,Two-stage grinder, Doubel grade crusher

-

After sale service:

-

Life-long Service

-

Spare Parts Supply:

-

Life Long Provide

-

Feeding size:

-

According to different models

-

Local Service Location:

-

Ukraine

-

Certification:

-

ISO9001:2015

Products Description

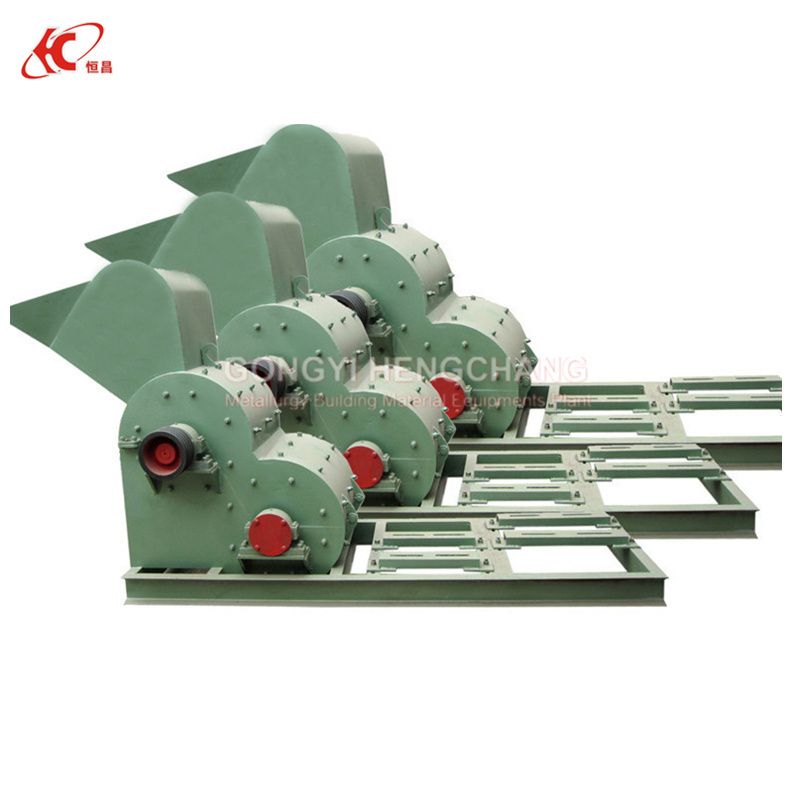

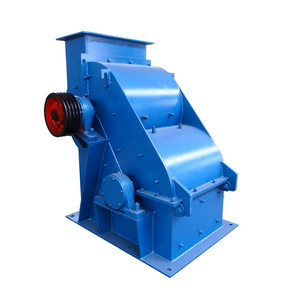

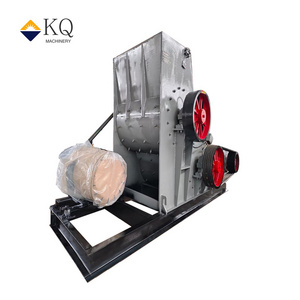

Double stage hammer mill crusher

Details Images

Working principle

When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them, the crushed products meeting the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushing area by the hammers for being re-crushed until they reached the required size. When the bulk material into the machine, hit by the hammerhead and stopped by material bracket. That's not only increase the contact area between material and hammerhead but also avoid sudden infarction of the rotor. After the impact, bulk materials hit themselves on the crushing cavity. Then the stones overflow from the straight screen or falling and been hammered again forming the stones. At last discharged from outlet of the hammer crusher.

Product Characteristics

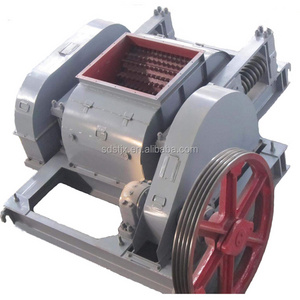

The double stage hammer crusher is equivalent to two hammers broken into one, which is reasonably combined into a whole. Two sets of rotors are used in series and have the following characteristics:

1. Two rotors up and down crushing

The two sets of rotors connected in series make the materials crushed by the upper rotor immediately crushed again by the hammer head of the lower rotor rotating rapidly. The materials in the inner cavity collide with each other quickly and crush each other to achieve the effect of hammer powder and powder powder. Unload directly.

2. There is no grate bottom, high-humidity material, and it will never be blocked

The traditional grinder with grate sieve plate is not suitable for raw materials with a moisture content higher than 8%. When the raw material moisture content is higher than 10%, it is easy to cause serious blockage, so that the hammer head cannot rotate, the material cannot be discharged, or even burn A bad motor seriously affects production.

The design of this machine has no grate bottom, no strict requirements for the moisture content of the material, and there is no problem of blocking the sieve plate, and there is no problem that the fine powder cannot be discharged in time, repeated crushing, so the crushing efficiency is high, and there is no hammer head. Invalid wear phenomenon.

3. Wear-resistant combined hammer head

High alloy wear-resistant hammer head. The hammer head and hammer handle are used in combination, only the hammer head is changed, not the hammer handle.

4. Unique shift gap adjustment technology

No repair is needed after the hammer head is worn, and the mobile position can be used repeatedly. One pair of hammer heads can be used with three pairs of hammer heads.

5. Hydraulic manual start casing

Only one person can easily open and close, which is not only light, fast, safe and reliable, but also easy to maintain.

Henan Warwick Machinery, a professional manufacturer of two-stage crusher, two-stage crusher is equivalent to two hammers broken into one, reasonable combination into a whole, two sets of rotors used in series. The two sets of rotors connected in series make the material crushed by the upper rotor be crushed again by the hammer head of the lower rotor which rotates rapidly.

Our Advantages

Hammer head

The weight of the hammer head can be customized according to thecustomer's requirements. The hammer head is made of new high-quality multi-element high chromium manganese steel composite casting, and its service life is several times that of the general hammer head.

Spindle

The material of the spindle is made of high quality alloy steel, which is processed by ultrasonic inspection for quenching and tempering.

High strength steel carburizing heat treatment was used to improve the wear resistance of hammer disc and hammer hole.

Lining plate and strike plate

In order to prevent the abrasion of the frame, the inner wall of the frame is made of manganese steel. The striking plate is made of high-strength steel and quenched and strengthened. The superior abrasion resistance and impact resistance of the lining and striking plate are guaranteed.

Certifications

Hammer crusher CE Certification

ISO Quality System Identification

Motor CE certification

Product Paramenters

|

Model |

SCP 600×400 |

SCP 600x600 |

SCP800×600 |

SCP 900×800 |

SCP 1000x800 |

|

Feeding Size ( mm ) |

≤100 |

≤150 |

≤200 |

≤260 |

≤400 |

|

Outlet Size ( mm ) |

≤3 (<2mm above 90%) |

≤3 (<2mm above 80%) |

≤3 (<2mm above 80%) |

≤ 3 (<2mm above 80%) |

≤3 (<2mm above 80%) |

|

Capacity ( t/h ) |

15-25 |

15-30 |

50-70 |

50-90 |

60-120 |

|

Motor Power ( kw ) |

18.5+22 |

22+22 |

37+45 |

55+75 |

75+55 |

|

Dimensions ( L× W ×H ) ( mm ) |

2560×1020×1650 |

2760×1280×1750 |

3760×1314×2140 |

3870×1700×3150 |

4500×1700×3150 |

Recommend Products

Hot Searches