- Product Details

- {{item.text}}

Quick Details

-

Precision:

-

2,5,10,15,20μm

-

Temperature:

-

-10°c - 70°c

-

Filtration efficiency:

-

≥4μm,98%

-

Function:

-

Removes 99% of water and 95%-98% of other contamination

-

Material of filter elements:

-

Jingyuan polymeric membrane(Back-flushable with 2-3 service life)

-

Filter grade:

-

One

-

Connection:

-

DN20

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Name:

-

Best diesel purifier fuel filter water separator system

-

Application:

-

Diesel, Aviation kerosene

-

Precision:

-

2,5,10,15,20μm

-

Temperature:

-

-10°c - 70°c

-

Filtration efficiency:

-

≥4μm,98%

-

Function:

-

Removes 99% of water and 95%-98% of other contamination

-

Material of filter elements:

-

Jingyuan polymeric membrane(Back-flushable with 2-3 service life)

-

Filter grade:

-

One

-

Connection:

-

DN20

Best diesel purifier fuel filter water separator system

| Name | Diesel Filtrator |

| Model | JY-T32A |

| Brand Name | JINGYUAN |

| Place of Origin | Liaoning , China (Mainland) |

| Flow rate | 20~40 L/min(5.28 GPM~10.57 GPM depends on the quality of oil) |

| Precision | 2,5,10,15,20μm |

| Material of filter elements | Jingyuan polymeric membrane(Back-flushable with 2-3 service life) |

| Pressure | 0.2~0.3Mpa |

| Temperature | -10°c - 70°c |

| Filtration Efficiency | ≥4μm,98% |

| Filtration Level | 2 |

| Voltage | 220V/380V |

| Connection | DN20 |

| Medium | Bio-diesel • Diesel Fuels • Light oils • Aviation Kerosene/ Aviation fuel |

| Dimension | 680*480*660 mm |

| Weight | 84Kg |

Guaranteed to Provide Clean Oil Filtration Systems ( membrane separation, Microfiltration )

Filtration & Separation Solutions for: Solid Particulate and water removal

Suitable for: Bio-diesel • Diesel Fuels • Light oils • Aviation Kerosene/ Aviation fuel

Function: Its design makes it ideally suited to removing reliably in a single-pass 98% of contamination and free & emulsified water to less than 2 ppm , thereby guaranteeing the required cleanliness.

JY-T32A allows for the removal of ultra-fine particulates and debris, thereby immediately reducing the risk of contamination-induced damage to parts and machinery. To quickly and reliably achieve very low particle counts in fuel oils to meet or exceed stringent OEM cleanliness specifications (as low as ISO 14/12/11)

These particles are not usually visible, but are in molecular form until they are adsorbed onto the filter media, or until they agglomerate and settle out in fuel tanks as “sludge.” The contaminants must be removed from diesel fuel before it reaches the engine .

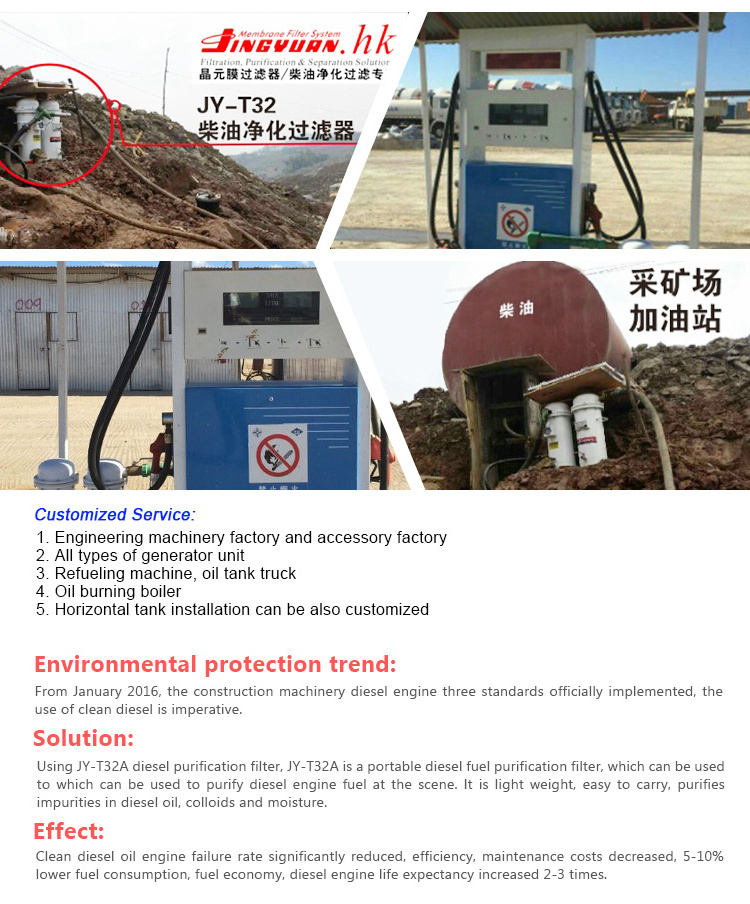

Engineering Machinery Field Site Diesel Refuel and Purification

Features:

· Single pass cleanness: High efficiency filter elements remove particulate contamination down to 5-micron.

· Small filter size keeps the lightweight in comparison to competitor brands with the same flow rate.

· Back-flushable elements reduces frequency of element replacements.

· P ressure gauges give positive indication when filter elements are plugged and need to be changed.

Filter elements:

Back-flushable long service life (2-3 years)Filter elements ( membrane separation, Microfiltration ).

To quickly and reliably achieve very low particle counts in fuel oils to meet or exceed stringent OEM cleanliness specifications, we utilize the latest most efficient elements micro membrane technology . Our filter elements have more media and surface area than other conventional elements, resulting in lower clean initial pressure drops, better filtration performance, higher dirt-holding capacities, and longer life.

The filter elements are sintered and stitched for maximum durability, and are available in a wide variety of micron sizes depending on the particle size distribution within the fuel oil.

Micron ratings of2, 5 , 10 , 15 , 20μm and 25 are available. The 2 micron media typically achieves an ISO cleanliness code of 15/13/9 or better. The elements will ensure that Diesel Fuel meets or exceeds all new stringent Fuel Oil Cleanliness (Meets stringent ASTM D975 and ISO 4406 fuel cleanliness standards).

Microfiltration:

Removes all fine contamination particles down to 5-10 microns in size. The clean fuel is returned to the tank via the return hose. The pressure gauge will advise the technician when the filter requires replacement.

Various models to handle different flow rates

| Diesel Filtrator | ||||

| JY-T32A | Model | JY-T100A | ||

|

20~40 L/min 5.28 GPM~10.57 GPM

depends on the quality of oil |

Flow rate |

40~80 L/min 10.56 GPM~21.14 GPM

depends on the quality of oil |

||

| 2,5,10,15,20μm | Precision | 2,5,10,15,20μm | ||

|

Jingyuan polymeric membrane

Back-flushable with 2-3 service life |

Material of filter

elements |

Jingyuan polymeric membrane

Back-flushable with 2-3 service life |

||

| 0.2~0.3Mpa | Pressure | 0.2~0.3Mpa | ||

| -10°c - 70°c | Temperature | -10°c - 70°c | ||

| ≥4μm,98% | Filtration Efficiency | ≥4μm,98% | ||

| 2 | Filtration Level | 3 | ||

| 220V/380V | Voltage | 220V/380V | ||

| DN20 | Connection | DN65 | ||

|

Bio-diesel • Diesel Fuels • Light oils

• Aviation Kerosene/ Aviation fuel |

Medium |

Bio-diesel • Diesel Fuels • Light oils

• Aviation Kerosene/ Aviation fuel |

||

| 680*480*660 mm | Dimension | 1370*410*830 mm | ||

| 84Kg | Weight | 125Kg | ||