- Product Details

- {{item.text}}

Quick Details

-

The gas source::

-

0.2-0.6Mpa 0.6m3/h

-

Processing noise::

-

<=75db

-

Relative::

-

<90%

-

Outside dimension(L*W*H)::

-

4800X1600X3080mm

-

Rated current;:

-

8.8A

-

Operating noise::

-

≤85db

-

dish Head processing range:

-

diameter 400mm-5000mm

-

Protection level::

-

IP55

-

After-sales Service Provided:

-

Free spare parts, Online support, Video technical support

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Power supply::

-

380V/50HZ

-

Temperature::

-

-10-40℃

-

The gas source::

-

0.2-0.6Mpa 0.6m3/h

-

Processing noise::

-

<=75db

-

Relative::

-

<90%

-

Outside dimension(L*W*H)::

-

4800X1600X3080mm

-

Rated current;:

-

8.8A

-

Operating noise::

-

≤85db

-

dish Head processing range:

-

diameter 400mm-5000mm

-

Protection level::

-

IP55

-

After-sales Service Provided:

-

Free spare parts, Online support, Video technical support

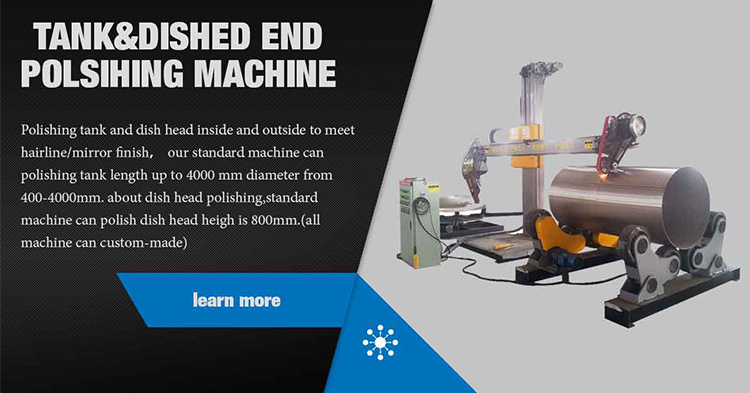

Portable stainless steel steel tank &dish pipe buffing polishing machine

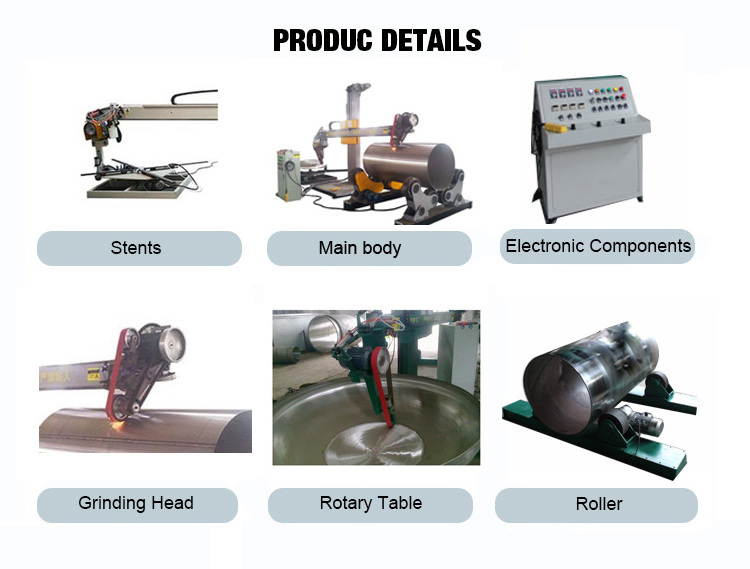

Machine tool structure

1.Including the mechanical part, electrical control part

(1.1) The mechanical part is composed of polishing system, polishing wheel walking system, workpiece reversing table, and the main workpiece is welded structural part

(1.2)The electrical control part consists of control cabinet, frequency converter and motor.

|

1. The column |

2. The beam |

3. Walking bracket |

4. Column base |

|

5.Power distribution cabinet |

6. Head main motor |

7. Lifting motor |

8. Walking motor |

|

9. Rotary head motor |

10. Sealing cylinder |

11. Head grinding wheel |

12. Head rotary base |

|

13. Tank body rotary motor |

14.Tank body rotary base |

15. Tank wheel |

16.Main motor of tank body |

Product Description

1. Grinding with abrasive belt, high efficiency, low noise and less dust. Using thousands of impeller (or wheel dipped emery cloth, wool wheel) polishing, mirror polishing can be achieved.

2. Integrated belt polishing machine, which can respectively polish different parts such as tank body and head, grinding, and select the abrasive belt grinding head with processing precision Ra≤0.2μm (mirror effect). Both workpiece rotation and lateral feed are variable frequency stepless speed regulation, which further improves work efficiency.

3. One device can polish the inner and outer surfaces of the tank and the head, equipped with two sets of grinding heads and two sets of workpiece turning mechanisms.

Want to see this tank & dish polishing machine more information! More>>

Want to know this tank & dish polishing machine more information! Contact us>>

dis|

Specification of grinding and polishing machine |

|

|

Outer Dimension |

4700*1600*3100 mm |

|

Machine Weight |

2000 KG |

|

Input Power |

8 KW |

|

Control System |

PLC/CNC |

|

Polishing Materials |

Abrasive belt,Flap wheel,Nylon,Hemp wheel,Cloth wheel |

|

Note |

Our products all Non-Standard Customization |

|

Specifications of Working Pieces |

|||

|

Work Piece Size |

Tank/Vessel/Cylinder |

Diameter |

400-5000 mm |

|

Max Length |

6000 mm |

||

|

Max Weight |

10 T |

||

|

Dished End/Tank Top |

Diameter |

400-5000 mm |

|

|

Depth |

2500 mm |

||

|

Max Weight |

10 T |

||

|

Material |

stainless steel,aluminium alloy,carbon steel,red copper,etc. |

||

|

Surface Roughness |

Ra ≤ 0.4 μm (Mirror Finished) |

||

|

Product Eifficiency |

6 - 12 square meters per hour |

||

Mainly application for leisure food factory equipment, winery equipment, fruit and vegetable processing plant equipment, frozen food factory equipment, seasoning processing equipment, meat processing plant equipment head curling machine, flat bottom crimping machine, conical spiral machine, Edge turning machine, cylinder body crimping machine, beer tank curling machine, oil tank head crimping machine, etc.

Mainly application for leisure food factory equipment, winery equipment, fruit and vegetable processing plant equipment, frozen food factory equipment, seasoning processing equipment, meat processing plant equipment head curling machine, flat bottom crimping machine, conical spiral machine, Edge turning machine, cylinder body crimping machine, beer tank curling machine, oil tank head crimping machine, etc.

Company specializing in tank making machinery equipments,such as dish end machine,triming cutting machine,Necking machine, Longitudinal seam welding machine,Circular Seamwelding machine,cutting machine,bending machine,rolling machine etc.

Want to know other machines related to this tank welding machines! More>>