- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity

-

Weight:

-

1~5 Tons

-

Year:

-

2020

-

Warranty:

-

3 years from commissioning

-

Name:

-

1000L experiment microbrewery beer equipment for hot sale

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/Steam/Direct fired heating

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

Plants Type:

-

Turnkey or Customerized

-

Application:

-

1000L experiment microbrewery beer equipment for hot sale

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tiantai OEM

-

Voltage:

-

customized

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity

-

Weight:

-

1~5 Tons

-

Year:

-

2020

-

Warranty:

-

3 years from commissioning

-

Name:

-

1000L experiment microbrewery beer equipment for hot sale

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/Steam/Direct fired heating

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

Plants Type:

-

Turnkey or Customerized

-

Application:

-

1000L experiment microbrewery beer equipment for hot sale

-

Certification:

-

CE ISO

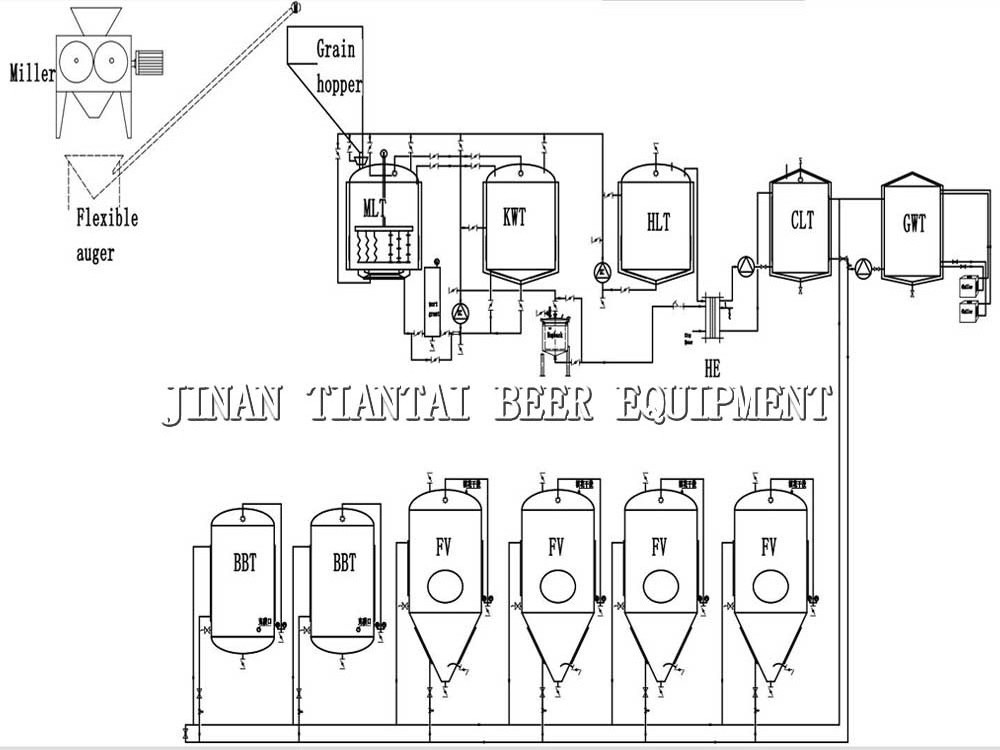

Microbrewery equipment is typically applied to breweries that are much smaller than large-scale corporate breweries and are independently owned. Such breweries are generally characterized by their emphasis on flavor and brewing technique. We offer a Microbrewery (mini brewery) with the productivity of 1000L (10 hl) to 5000L (50hl) per brew. The service includes: complete set of microbrewery equipment, installation turn key, recipes and technology of branded beers, staff training and more. Microbrewery comes complete "turnkey" The performance of your Microbrewery (Brewery and mini brewery), if necessary, can be increased in the future..The complete setup of industrial brewery equipment is equipped with advanced technology and specifications.our products enable to do milling,mashing,fermentation,filtration,filling and other related process.

Grain miller

Flexible Auger

Function: conveyor the malt from miller to mash tun

Capacity:0.6t/h;Power:2.2Kw

Stainless steel screw;PVC pipe

Conveyor distance:6m

Weight:80kg

Grain Hopper

Function:Storage

Capacity:It is up to the ratio of the malts and water during brewing.

Material:Stainless steel

Brewhouse Unit

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

Infusion or decoction brewing methods are designed exactly

Stainless steel or copper cladding are popular

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings and fittings

Fermentation Unit

Standard stainless steel conical cylindrical fermentation tanks

Single size as brewhouse is common used in restaurant

Tanks quantity is exactly calculated by fermentation cycle for various beers

All manhole, valves, pressure gauges, fittings etc are included

Function:

Wort Fermentation or maturation

Tank Capacity:

50L-50000L (+25% Headspace minimum)

Interior Shell:

SUS304 full welded; TH=3mm

Exterior Shell:

SUS304 full welded; TH=2mm

100% TIG welding with pure argon gas shield

Interior Finish:

Overall polishing to 0.2~0.4 μm without dead corner

Insulation

: Polyurethane; TH=80mm

Glycol Jacket:

Dimpled plate on cone and side

Beer Filter Unit(optional)

In restaurant or bar, beers are always served as craft beer without filtration

Bright Tank Unit

Function:

maturation, conditioning, service, carbonation

Tank Capacity:

50L-50000L (+25% Headspace minimum)

Interior Shell

: SUS304 full welded; TH=3mm

Exterior Shell:

SUS304 full welded; TH=2mm

100% TIG welding with pure argon gas shield

Interior Finish:

Overall polishing to 0.2~0.4 μm without dead corner

Insulation:

Polyurethane; TH=80mm

Glycol Jacket:

Dimpled plate on cone and side

Single size as fermenter is common used in restaurant or bar

All manhole, valves, stone, gauges, fittings etc are included

Glycol cooling System

Glycol water supply for wort cooling and fermentation cooling.Its structure usually include Glycol water tun+1 or 2 chillers(the cold liquor tun is optional)+Glycol water pump

Glycol Water Tank:

Inner-Jacket (SUS304 SS) thickness: 3.0mm;

External-Jacket (SUS304 SS) thickness: 2.0mm;

100% TIG welding with pure argon gas shield

Interior Finish: Overall polishing to 0.2~0.4 μm without dead corner

Insulation: Rock wool; TH=80mm

Usually for the large beer system,we suggest with chiller+glycol water tank+cold water tank for the glycol cooling system.The smaller beer system with chiller +glycol water tank

Control System

CIP System

There is two kinds of CIP system,one is the CIP pump,the other is CIP cart unit.For the small volume beer brewing system below 600L,CIP pump is enough for cleaning.For the large beer brewery equipment,it is better to use the CIP cart for cleaning tanks and pipes.

Caustic Tank:

Material is SUS304;Thickness is 2mm;Interior Finish Polish: 0.2~0.4 μm

Sterilization Tank:

Material is SUS304;Thickness is 2mm;Interior Finish Polish: 0.2~0.4 μm