- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WRM(OEM)

-

Model Number:

-

Bearing Ball

-

Diameter:

-

1/8 3/16 1/4 5/16 3/8 1/2 13/32 8.0mm 9.0mm

-

Hardness:

-

HRC 61-66

-

Grade:

-

G10-G1000

-

Appliction:

-

Bearing,Ball bearings,bicycles,automobile industry,etc.

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Energy & Mining, Advertising Company

-

Material:

-

Stainless steel,carbon steel,chrome steel,etc.

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WRM(OEM)

-

Model Number:

-

Bearing Ball

-

Diameter:

-

1/8 3/16 1/4 5/16 3/8 1/2 13/32 8.0mm 9.0mm

-

Hardness:

-

HRC 61-66

-

Grade:

-

G10-G1000

-

Appliction:

-

Bearing,Ball bearings,bicycles,automobile industry,etc.

Ball Bearing Balls

Different sizes and Model Number available;

We can also provide OEM service according to your requirement.

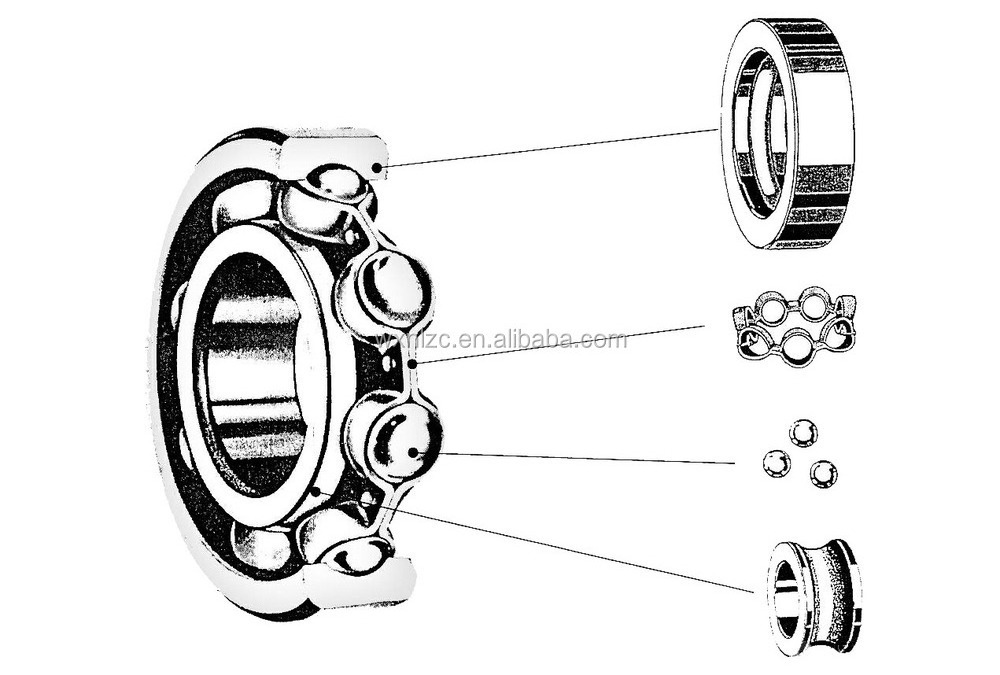

Steel ball according to the production process is divided into grinding ball, forging steel, cast steel ball. According to the materials can be divided into bearing steel ball, stainless steel ball, steel ball, punch ball, alloy ball and so on. Alloy steel ball is the carbon, chromium, manganese, molybdenum, etc as the main metal elements added, and through the way of forging, casting and rolling, spinning generated a globular shape alloy wear-resistant body, it is the ball in mines, crushing industry the most important part of cement ball and so on.

Applicable industry

Crushing industry

Bearing industry

Steel balls are widely used in bearings, hardware, electronics, wrought iron, mechanical equipment, electric power, mining, metallurgy and other fields.

Steel ball is the basis of the important parts, especially the precision industrial ball plays a huge role in economic development. In some special conditions, often need special material steel ball, to complete the required to achieve the function of the different environment. In fact, some special material steel ball has been widely used in various fields, including 9 cr18, 3 cr13 stainless steel, copper, aluminum, steel and titanium alloy agate, glass, ceramic ball, etc. Their popularization and application, not only promoted the development of the steel ball manufacturing, but also promote the technology development of related industries, science and technology progress.

Steel ball production process after the steel ball automatic cleaning, automatic surface testing (automatically weed out unqualified products), automatic rust and counting packaging, is the key factor affecting the quality of steel ball. Steel ball surface testing is an indispensable process in the manufacturing process of steel ball. Steel ball surface testing mainly includes surface scratch, rust, spots and so on the surface of the test. Light steel ball production process: stamping, grinding, hardening, grinding hard - appearance - lapping, cleaning, rust, finished product packaging.

(1)Material density effect: steel, cast iron, alloy steel ball, etc., the density of different material is different, the density of steel bigger than cast iron, alloy steel, in accordance with the main alloy elements and content of different density and different.

(2)Steel ball manufacturing methods: rolling and forging steel ball of the compact structure, so the density is big, the casting of cast steel, cast iron ball or casting alloy ball and so on organization is not very dense, even including porosity, so the density is small.

(3)Steel ball metallography organization: martensite and austenite, bainite, ferrite density under different crystal structure is not the same, the crystallization degree of fineness may also be affected.

(4)Chemical elements: steel ball as the chemicals in finished products such as iron, carbon, chromium, manganese, sulfur, phosphorus and other elements, the hardness, impact abrasion of steel ball, the influence of different level in general, the chromium content is big, the high wear resistance of steel ball.

There are many kinds and types of bearings,pictures may not be the product figure in fact , If you are interested please contact us, We will go to the warehouse to photograph the actual photos for you and do our best to meet your requirements.

1. We can change the rubber seal color according to your actual requirements.

2. Customized the marks based on your requirements.

3. Choose the different package to your needs.

S ample: Usually by EMS, DHL, UPS, TNT, Fedex. Anyway as you like.Bulk order:Usually by sea.

Delivery: Within 7 days working day for Sample or below 100 pcs ,30-45 days working day for large quantity. The shipment we will arrange as soon as possible. Of course, if it is a custom products,the shipping time will delay.

Warranty: Six months warranty time for the tracker unit from the delivery date leave factory, excluded the accessories.

Payment: It can be through T/T, L/C. The specific terms determined according to the quantity of the goods, etc.

Please inform us when the payment made, so that we are able to arrange the productions ASAP.

Over 10 years experience,we can provide professional solutions for customers.

Send your inquiry details in the below,click " Send " Now!!!