▶

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

74KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

17000*1300*2200mm

-

Year:

-

2023

-

Product name:

-

Puffed Food Production Line

-

Application:

-

Snack Food Processing Machine

-

Function:

-

Multifunctional

-

Keywords:

-

Corn Puff Make Machine

-

After-sales Service Provided:

-

Online Support

-

Final product:

-

Snack Pellets

-

Shape:

-

Customrized

-

Item:

-

Commercial Snack Food Machine

-

Advantage:

-

Easy Operation High Performance

-

MOQ:

-

1 Set

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

orangemech

-

Power:

-

74KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

17000*1300*2200mm

-

Year:

-

2023

-

Product name:

-

Puffed Food Production Line

-

Application:

-

Snack Food Processing Machine

-

Function:

-

Multifunctional

-

Keywords:

-

Corn Puff Make Machine

-

After-sales Service Provided:

-

Online Support

-

Final product:

-

Snack Pellets

-

Shape:

-

Customrized

-

Item:

-

Commercial Snack Food Machine

-

Advantage:

-

Easy Operation High Performance

-

MOQ:

-

1 Set

◆ Product Description

Introduction

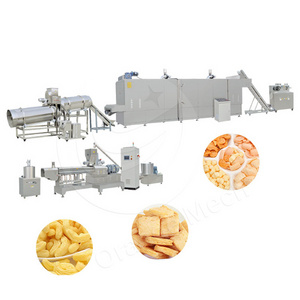

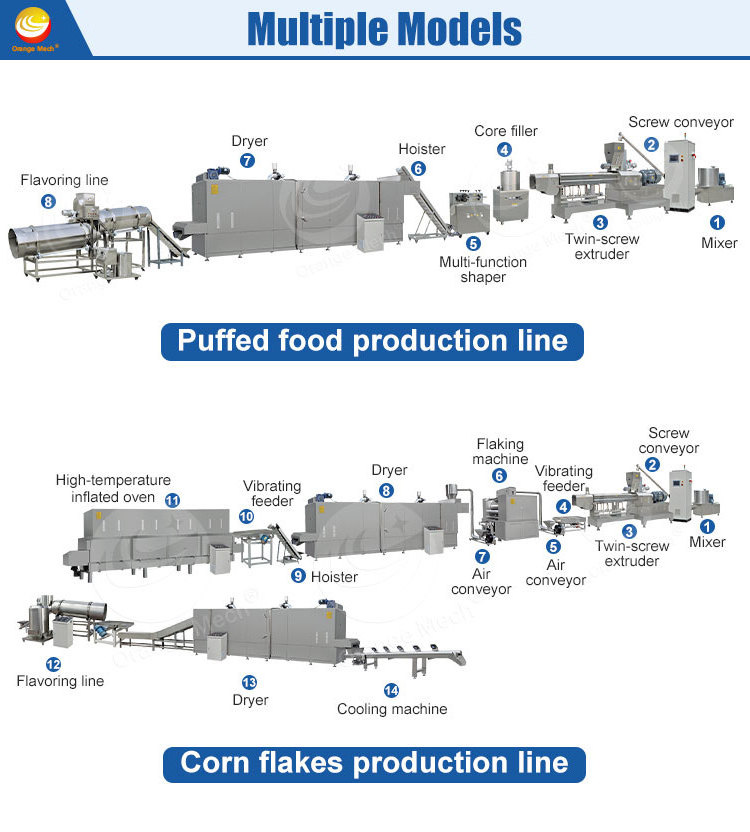

The Puffed Food production line completes the preparation of raw materials, extrusion and puffing, sandwiching, molding, cutting, spraying, seasoning and finished products in one go, with a high degree of automation. This production line has the characteristics of multiple optional models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation.The puffed food has a crispy texture, is easy to digest, and has a unique aroma, making it an ideal snack food for consumers.

Application

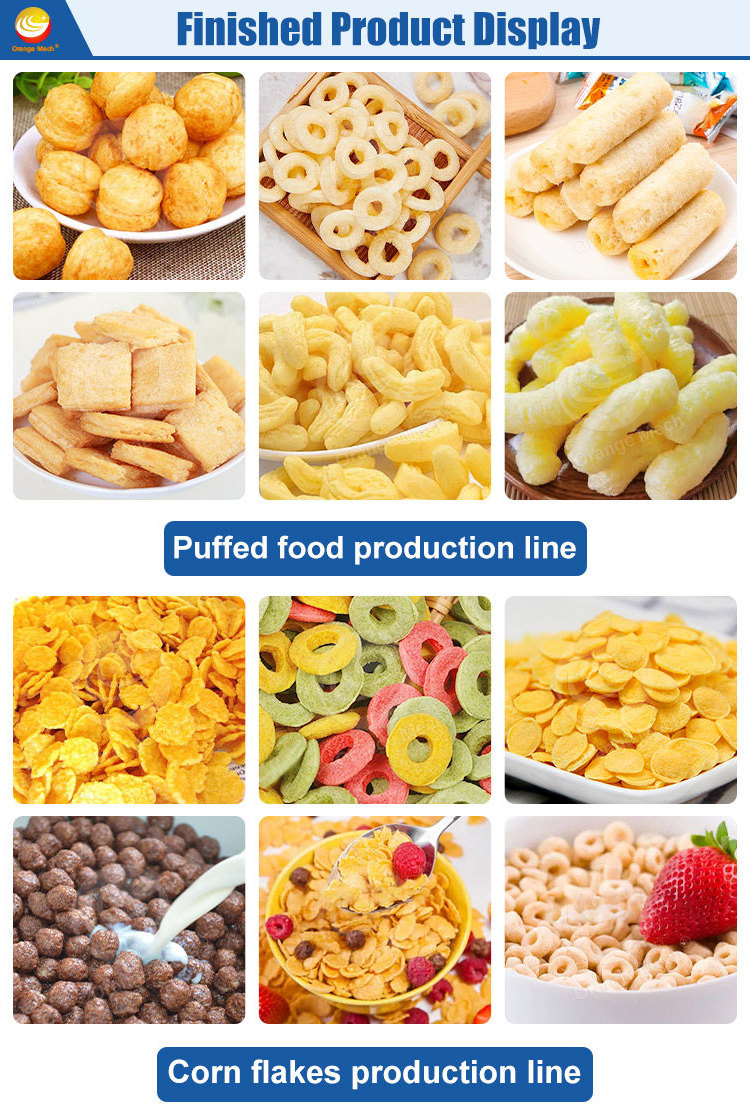

By changing the mold and selecting the appropriate production process, puffed products such as sandwich rice crackers, sandwich cakes, wheat barbecue, wheat-flavored chicken nuggets, nutritious breakfast, and corn flakes can be produced.

Feature

1.

The extruder model has novel design, compact structure, simple and convenient use, and convenient operation and maintenance.

2.

The transmission system of chemical food equipment is stable, safe and reliable, durable and has a low failure rate.

3.

The key components of the automatic food puffing machine are made of special alloy materials and are heat-treated. They have a long service life and low manufacturing costs.

4.

The screw design of the extruder has a strong self-cleaning effect, and the screw groove can be cleaned automatically. Therefore, when changing the formula and product type, there is no need to stop the machine for cleaning.

5.

Different templates can be configured according to needs to produce products of different specifications and material shapes.

◆ Product Details

parameter

|

model

|

Installed power

|

Actual power

|

capacity

|

Dimensions

|

|

orangemech-65Ⅲ

|

74KW

|

52KW

|

100-150kg/h

|

1700*130*220cm

|

|

orangemech-70

|

105KW

|

75KW

|

200-260kg/h

|

2000*150*220cm

|

|

orangemech-85

|

205KW

|

150KW

|

400-500kg/h

|

3000*150*260cm

|

|

orangemech-CF-65Ⅲ

|

130KW

|

90KW

|

100-150kg/h

|

3900*130*250cm

|

|

orangemech-CF-70

|

160KW

|

120KW

|

200-260kg/h

|

4100*150*250cm

|

|

orangemech-CF-85

|

190KW

|

140KW

|

300-500kg/h

|

4300*350*430cm

|

◆ Product Photograph

◆ Packaging & Shipping

▶

Install waterproof membrane to reduce dust and water pollution.

◆ Related Machines

Hot Searches