- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

F-LHD450

-

Total Power(KW):

-

470

-

Condition:

-

New

-

Supplier:

-

FAR EAST(CHINA)MACHINERY CO.,LTD

-

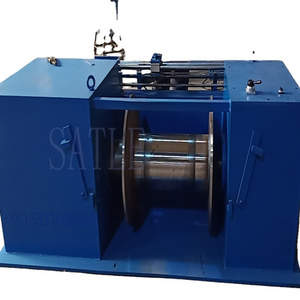

Color:

-

Blue

-

Spare parts:

-

cheap but high quality

-

After-sales service:

-

reliable and satisfactory

-

Application:

-

Electric wire and cable making industry

-

Name:

-

Copper/aluminum wire drawing line

Quick Details

-

Use:

-

Drawing

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

FE

-

Model Number:

-

F-LHD450

-

Total Power(KW):

-

470

-

Condition:

-

New

-

Supplier:

-

FAR EAST(CHINA)MACHINERY CO.,LTD

-

Color:

-

Blue

-

Spare parts:

-

cheap but high quality

-

After-sales service:

-

reliable and satisfactory

-

Application:

-

Electric wire and cable making industry

-

Name:

-

Copper/aluminum wire drawing line

Shanghai

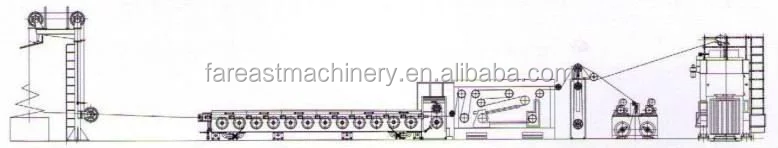

13D RBD making copper aluminum wire drawing machine with 800 coiler take up for cable size 1.2 -4.0mm of rod breakdown machine

Product Description

Usage

The machine is used to draw copper rod from Ø 8 mm to Ø 1.2~4.0 mm.

The machine is used to draw copper rod from Ø 8 mm to Ø 1.2~4.0 mm.

Main Parameters of Sliding Heavy-Duty Copper Wire Drawing Machine With Annealer

|

Item

|

F-LHD450/9

|

F-LHD450/11

|

F-LHD450/13

|

||

|

Inlet Wire Dia.(mm)

|

Ø 8

|

Ø8

|

Ø 8

|

||

|

Outlet Wire Dia.(mm)

|

Ø 2.0~4.0

|

Ø 1.5~4.0

|

Ø 1.2~4.0

|

||

|

Max Die No.

|

9

|

11

|

13

|

||

|

Drawing Capstan Dia.(mm)

|

450

|

|

|

||

|

Max. Line Speed(mm)

|

18

|

22

|

25

|

||

|

Main Motor Power(KW)

|

250

|

250

|

250

|

||

|

Total Power(KW)

|

725

|

750

|

750

|

||

|

Annealer Power

|

70V×5000A

|

|

|

||

|

Drawing Capstan

|

Coated with tungsten carbide

|

|

|

||

|

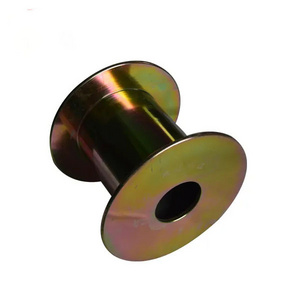

Dual Takeup Standard(mm)

|

PND500/630

|

|

|

||

|

Traversing Type

|

Motor type

|

|

|

||

|

Lubrication Type

|

Immersion and spraying

|

|

|

||

Main Parameters of Sliding Heavy-Duty Aluminum Wire Drawing Machine With Annealer

|

Item

|

F-LHD450/9

|

F-LHD450/11

|

F-LHD450/13

|

|

||

|

Inlet Wire Dia.(mm)

|

Ø 9/12.5

|

Ø9/12.5

|

Ø9/12.5

|

|

||

|

Outlet Wire Dia.(mm)

|

Ø 3.0~5.0

|

Ø 2.3~5.0

|

Ø 1.8~5.0

|

|

||

|

Max Die No.

|

9

|

11

|

13

|

|

||

|

Drawing capstan Dia.(mm)

|

450

|

|

|

|

||

|

Max. Line Speed(mm)

|

18

|

20

|

25

|

|

||

|

Main Motor Power(KW)

|

250

|

250

|

250

|

|

||

|

Total Power(KW)

|

385

|

385

|

385

|

|

||

|

Drawing Capstan

|

Coated with tungsten carbide

|

|

|

|

||

|

Dual Takeup Standard(mm)

|

PND500/630

|

|

|

|

||

|

Traversing Type

|

Motor type

|

|

|

|

||

|

Lubrication Type

|

Immersion and spraying

|

|

|

|

||

Components

Pay-off stand, main drawing machine,

wire accumulator,

automatic dual take-up device(or coiler according to customer),

wire pointer and stripper,

electrical control system, etc

Detailed Images

Main Capability Features

1) The drawing blocks are arranged in a horizontal single-bank tilt, and the distance between the cantilevers of all die holders are short, and in equal length, and have a strong stiffness.

2) The surface of drawing blocks is coated with tungsten carbide (powder), which is strong in hardness and abrasion resistance, and has a long life span.

3) The main drawing machine and fix capstan are driven separately, and all the dies can be changed conveniently and easily.

4) Continuous dual take up, automatic reel-change, the conductor elongation is not changed when changing the reel. The success rate of automatic reel-change is more than 99%.

5) Driven by DC motor, the imported PLC and touch Screen( Siemens of Preface) are convenient for operator to set and display the parameter on the touch screen.

1) The drawing blocks are arranged in a horizontal single-bank tilt, and the distance between the cantilevers of all die holders are short, and in equal length, and have a strong stiffness.

2) The surface of drawing blocks is coated with tungsten carbide (powder), which is strong in hardness and abrasion resistance, and has a long life span.

3) The main drawing machine and fix capstan are driven separately, and all the dies can be changed conveniently and easily.

4) Continuous dual take up, automatic reel-change, the conductor elongation is not changed when changing the reel. The success rate of automatic reel-change is more than 99%.

5) Driven by DC motor, the imported PLC and touch Screen( Siemens of Preface) are convenient for operator to set and display the parameter on the touch screen.

Finished Product

Packing&Shipping

After Sales Service

①Free service guarantee period is: 12 months after shipping (except wearing parts)

② Provides long term spare supply, technical support and maintenance service for the machine, but we will charge for travel fee

and other basic cost.

We guarantee when we get the information of the customer, our engineers will analyze immediately, then response as soon as

possible, if need our engineers come, 24hours will be arrived inland, and one to two week oversea based on getting visa on time.

② Provides long term spare supply, technical support and maintenance service for the machine, but we will charge for travel fee

and other basic cost.

We guarantee when we get the information of the customer, our engineers will analyze immediately, then response as soon as

possible, if need our engineers come, 24hours will be arrived inland, and one to two week oversea based on getting visa on time.

Company Introduction

Far East (China) Group Limited,

we design and produce metal casting equipment, wire drawing equipment, and cable production machinery of the highest quality. We pride ourselves on our various strengths that begin with product design and end with our excellent after-sale services to make sure that our customers are satisfied with their metal machinery. Feel free to browse our site and contact us if you have any additional questions about our company or products.

FAQ

A:I am newer on this field, I don't know how to plan?

Q : Every salesman of us can tell you how to plan the workshop ,how to install the equipment,how to save the costs and so on.

A: How can i install my machine when it arrives?

Q: We will send our engineers to your factory to install the machines and train your staff how to operate the machines

A:How about the spare part?

Q: We can offer you a spare parts list for your reference.

A : Which industries are mainly targeted at Far East's equipment?

Q : Wire and cable, enameled wire, electron beam, cutting line, magnetic wire,and S.S.wire etc.

Q : Every salesman of us can tell you how to plan the workshop ,how to install the equipment,how to save the costs and so on.

A: How can i install my machine when it arrives?

Q: We will send our engineers to your factory to install the machines and train your staff how to operate the machines

A:How about the spare part?

Q: We can offer you a spare parts list for your reference.

A : Which industries are mainly targeted at Far East's equipment?

Q : Wire and cable, enameled wire, electron beam, cutting line, magnetic wire,and S.S.wire etc.

Hot Searches