- Product Details

- {{item.text}}

Quick Details

-

Brand:

-

THORPMCT

-

Model:

-

F11-160A

-

Product name:

-

Homemade F11 Vertical Universal Dividing Head

-

Application:

-

Rotary Indexing Application

-

Usage:

-

Dividing Workpiece

-

Chuck:

-

200CHUCK

-

Model Number:

-

F11-160A

Quick Details

-

Brand Name:

-

THORPMCT

-

Material:

-

Cast Iron

-

Weight (KG):

-

180

-

Brand:

-

THORPMCT

-

Model:

-

F11-160A

-

Product name:

-

Homemade F11 Vertical Universal Dividing Head

-

Application:

-

Rotary Indexing Application

-

Usage:

-

Dividing Workpiece

-

Chuck:

-

200CHUCK

-

Model Number:

-

F11-160A

Product Description

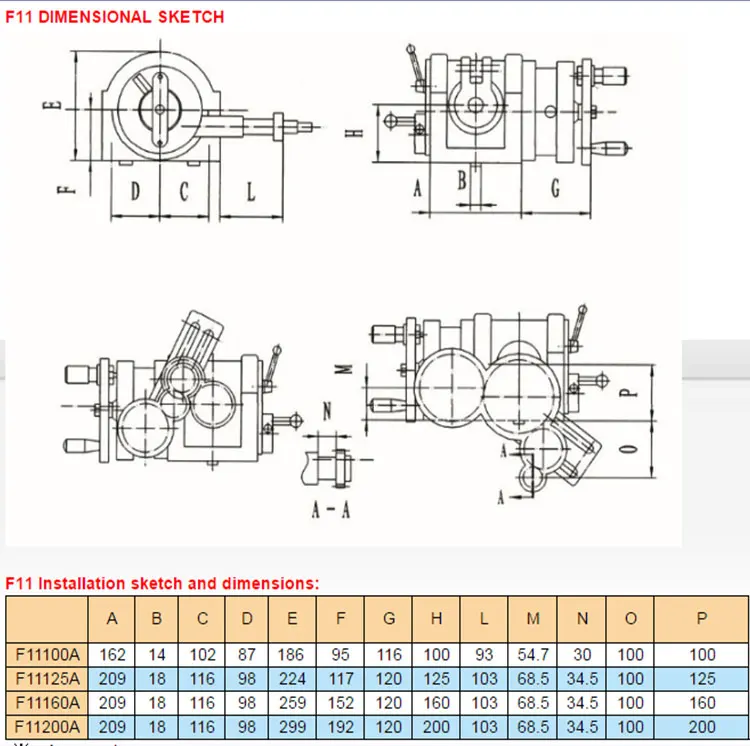

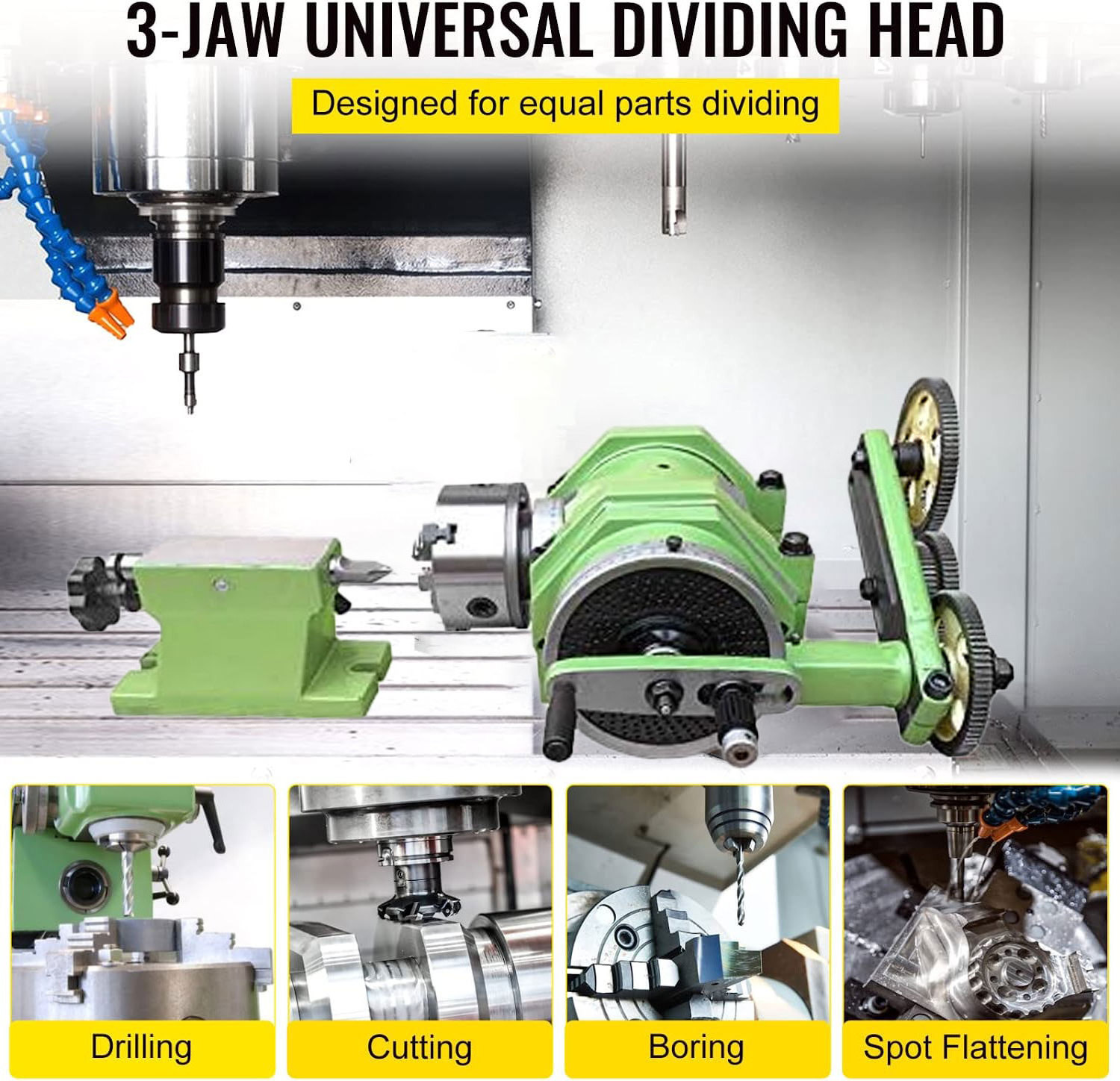

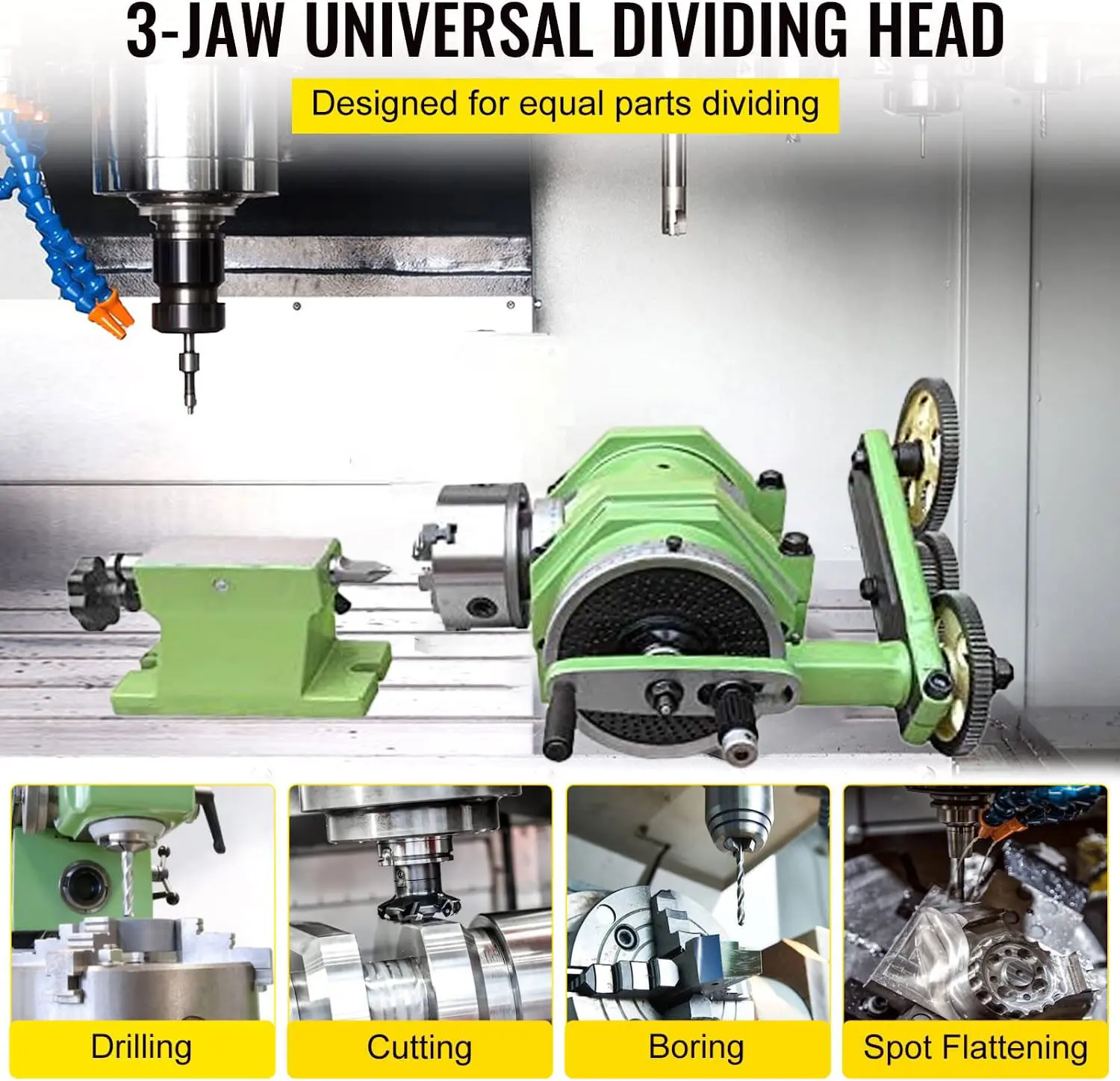

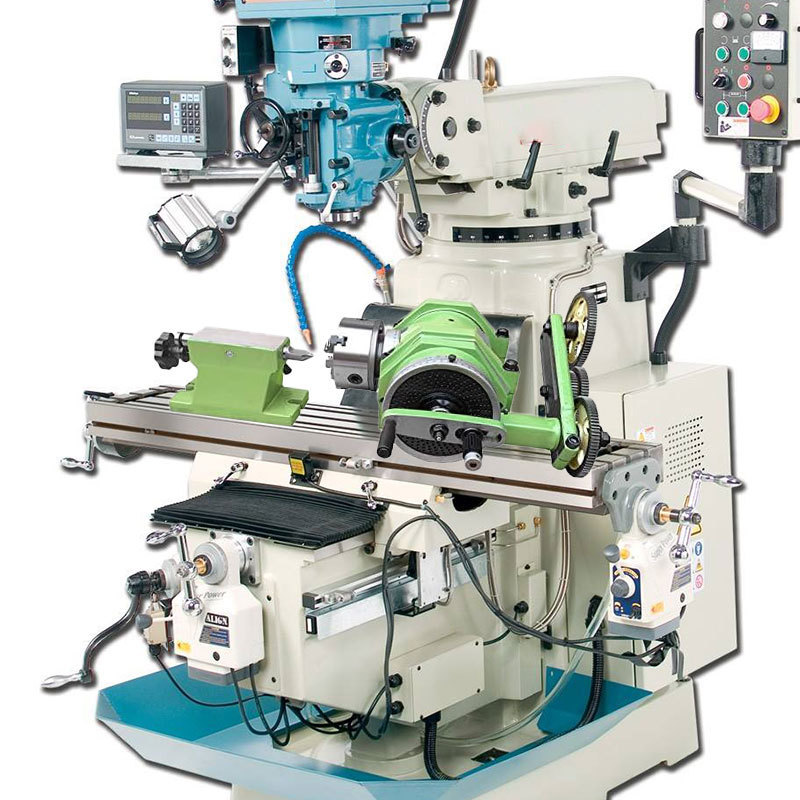

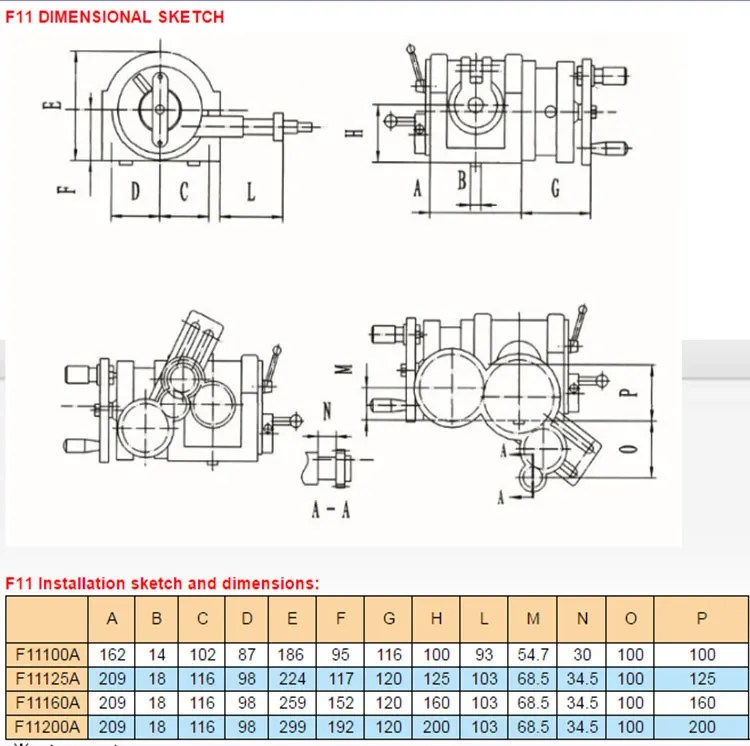

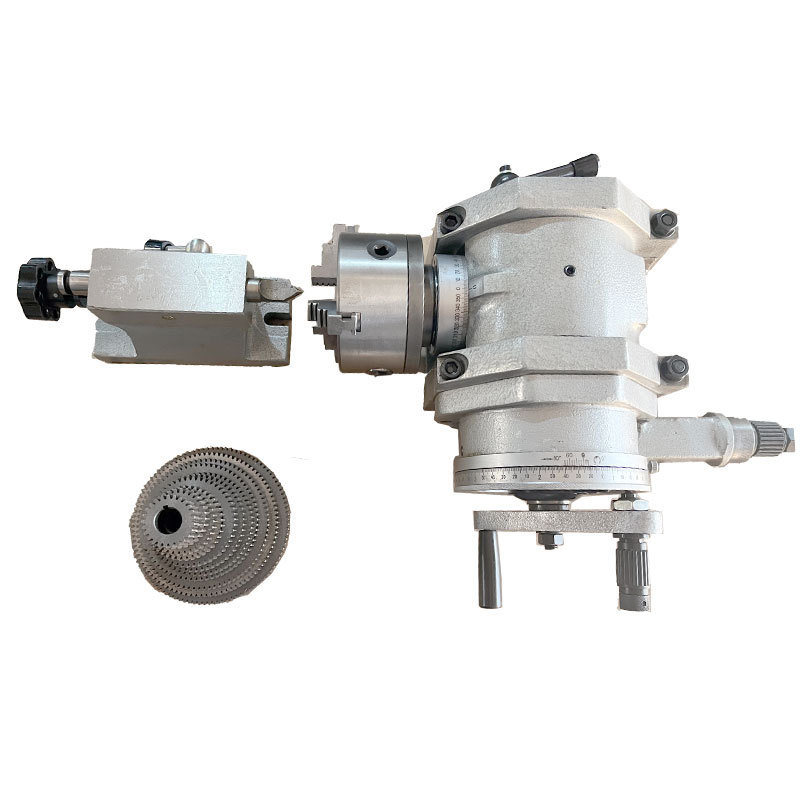

F11 universal dividing head

milling machine dividing head

The universal dividing head,Type F11100A,F11160A is one of the most important attachmenet for milling machine.With the help of this dividing head the workpiece held between centers,or on a chuck can be rotate to any angle as desired and the periphery of a workpiece can be divided into any divisions of equal parts.By means of all kinds of cutters,the dividing head can also help milling machine to perform the milling operation for flute spir gear,spiral gear,spiral flute,Archimedean cam,helical flute and etc.

The dividing head is equipped with a face plate that can be mounted onto the spindle nose.The workpiece can be mounted on the face plate,thus,cutting can be carried out on 4-sides of a workpiece.

F11125C F11160C is designed for the consumers special needed,the shafting is improved to support heavy load.

The universal dividing head,Type F11100A,F11160A is one of the most important attachmenet for milling machine.With the help of this dividing head the workpiece held between centers,or on a chuck can be rotate to any angle as desired and the periphery of a workpiece can be divided into any divisions of equal parts.By means of all kinds of cutters,the dividing head can also help milling machine to perform the milling operation for flute spir gear,spiral gear,spiral flute,Archimedean cam,helical flute and etc.

The dividing head is equipped with a face plate that can be mounted onto the spindle nose.The workpiece can be mounted on the face plate,thus,cutting can be carried out on 4-sides of a workpiece.

F11125C F11160C is designed for the consumers special needed,the shafting is improved to support heavy load.

|

Item

|

|

F11100A

|

F11125A

|

F11160A

|

F11200A

|

||||

|

Center hight mm

|

|

100

|

125

|

160

|

200

|

||||

|

Swivel angle of spindle from it's horizontal posirion(upward)

|

|

≤95°

|

|

|

|

||||

|

Horizontal position(downward)

|

|

≤5°

|

|

|

|

||||

|

Rotating angle of spindle for one complete revolution

of dividing handle |

|

9°(540grad.,1' each)

|

|

|

|

||||

|

Min reading of vernier

|

|

10"

|

|

|

|

||||

|

Worm gear ratio

|

|

1:40

|

|

|

|

||||

|

Taper of spindle bore

|

|

MT3

|

MT4

|

|

|

||||

|

Width of locating key.mm

|

|

14

|

18

|

|

|

||||

|

Diameter of short taper of spindlenose for mounting flange mm

|

|

Φ41.275

|

Φ53.975

|

Φ53.975

|

Φ53.975

|

||||

|

Hole number on index plate

|

1st plate

|

24,25,28,30,34,37,38,39,41,42,43

|

|

|

|

||||

|

|

2nd plate

|

46,47,49,51,53,54,57,58,59,62,66

|

|

|

|

||||

|

Change Gear

|

Module

|

1.5

|

2

|

|

|

||||

|

|

Teht Numbers

|

2.5,30,35,40,50,55,60,70,80,90,100

|

|

|

|

||||

|

Individual indexing error of the spindle for one

complete revolution of dividing handle |

|

±45"

|

|

|

|

||||

|

Cumulate error at any 1/4 periphery of spindle

|

|

±1"

|

|

|

|

||||

|

Max bearing Kg

|

|

100

|

130

|

130

|

130

|

||||

|

Net weight Kg

|

|

67

|

101.5

|

113

|

130

|

||||

|

Gross weight Kg

|

|

79

|

111.5

|

123

|

140

|

||||

|

Overall dimensions mm

|

|

616×465×265

|

635×530×530

|

710×535×342

|

710×535×342

|

||||

Specification

Product Category

Hot Searches