- Product Details

- {{item.text}}

Quick Details

-

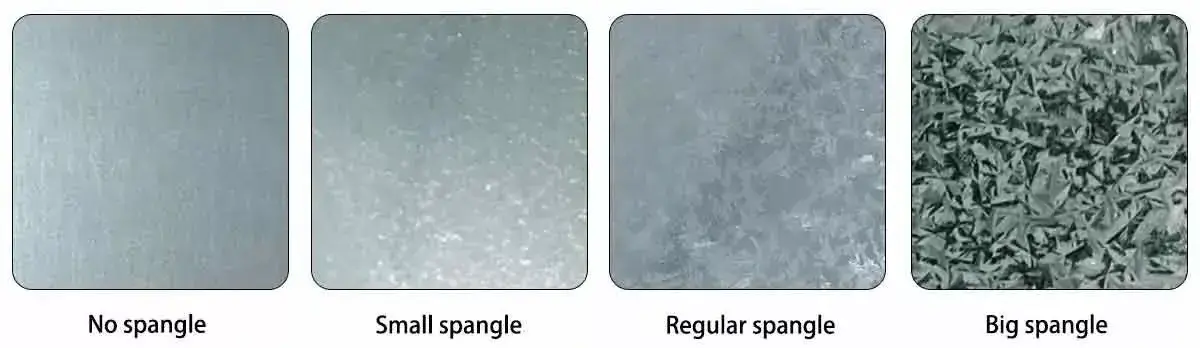

Spangle Type:

-

Regular Spangle

-

Place of Origin:

-

Vietnam

-

Grade:

-

Spcc Secc Dx51d Dx52d Dx53d

Quick Details

-

Type:

-

Steel Sheet

-

Thickness:

-

0.12mm-6mm

-

Coating:

-

Z10-Z29

-

Spangle Type:

-

Regular Spangle

-

Place of Origin:

-

Vietnam

-

Grade:

-

Spcc Secc Dx51d Dx52d Dx53d

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade |

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD,

S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440,SGH490,SGH540,

SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230),

SQ CR22 (255), SQ CR40 (275), SQ CR50 (340),SQ CR80(550), CQ, FS, DDS,

EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550);

or Customer’s Requirement

|

|

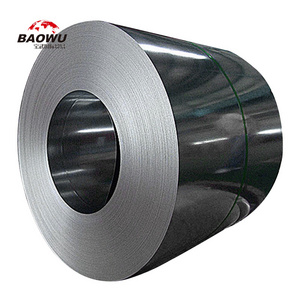

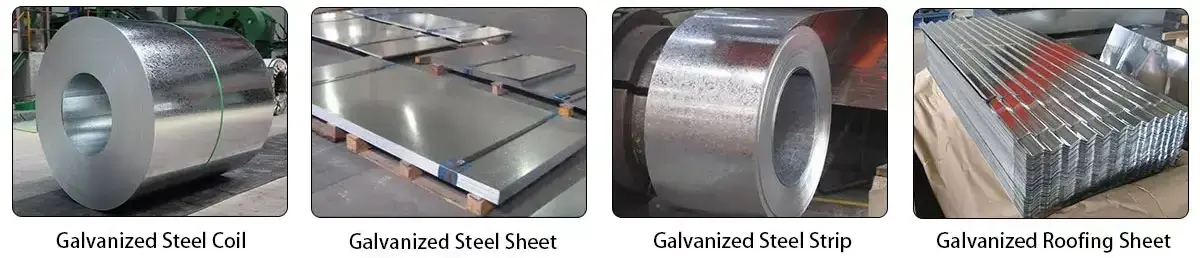

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.12-6.00mm,or customer's requirement

|

|

Width

|

600mm-1500mm, according to customer's requirement

|

|

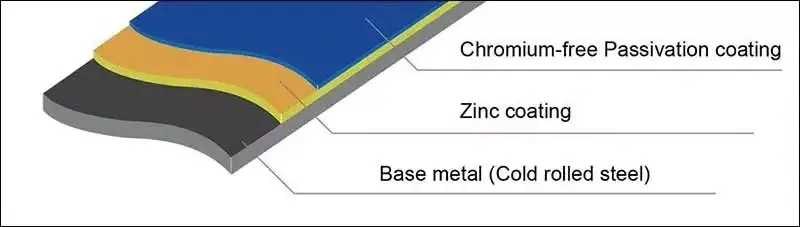

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

ID

|

508mm/610mm

|

|

Coil Weight

|

3-20 metric ton per coil

|

|

Package

|

Water proof paper is inner packing,galvanized steel or coated steel sheet is

outer packing , side guard plate,then wrapped by seven steel belt.or according

to customer's requirement

|

|

Export market

|

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America,

North America, etc

|

Product Introduction

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the

substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life

substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life

Diagram of Steel Surface Coating And Layers

Surface Structure

Product Display

Product Advantages

01.Anticorrosive :13 years in heavy industrial areas,50 years in the ocean,104 years in the suburbs and 30 years in cities.

02.Cheap :The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable :The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

04.Strong toughness :The galvanized layer forms a special metallurgical structure that can withstand mechanical

damage during transportation and use.

05.Comprehensive protection :Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy :Galvanizing process is faster than other coating methods

01.Anticorrosive :13 years in heavy industrial areas,50 years in the ocean,104 years in the suburbs and 30 years in cities.

02.Cheap :The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable :The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

04.Strong toughness :The galvanized layer forms a special metallurgical structure that can withstand mechanical

damage during transportation and use.

05.Comprehensive protection :Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy :Galvanizing process is faster than other coating methods

Production Line

Product Application

Packing And Shipping

FAQ

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers

need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to

purchase.

Q:What are the shipping ports?

A:You can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand is extremely

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to

purchase.

Q:What are the shipping ports?

A:You can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand is extremely

large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation

wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Q:What is your working time?

A:In general, our online service time is: 8:00-22:00, after 22:00, we will reply to your inquiry during the

Q:What is your working time?

A:In general, our online service time is: 8:00-22:00, after 22:00, we will reply to your inquiry during the

next working day.

Hot Searches