- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

hanchuang

-

Voltage:

-

220V/380v/110V

-

Dimension(L*W*H):

-

58*58*100cm

-

Weight:

-

100 kg

-

Name:

-

Automatic PVC Fabric cutting Machine

-

Function:

-

cutting paper, sticker, business card, PVC, PE , Foam ect

-

Speed:

-

58m/min

-

Cutting way:

-

Round Knife

-

Cutting precision:

-

0.1mm

-

Cutting Length:

-

0.1~9999.9mm

-

Automaticity:

-

PCL

-

Driving system:

-

Steping Motor

-

Package:

-

Wooden case

-

Advantage:

-

Working Stable

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

30-120pcs/min

-

Max. workable width:

-

customized

-

Place of Origin:

-

China

-

Brand Name:

-

hanchuang

-

Voltage:

-

220V/380v/110V

-

Dimension(L*W*H):

-

58*58*100cm

-

Weight:

-

100 kg

-

Name:

-

Automatic PVC Fabric cutting Machine

-

Function:

-

cutting paper, sticker, business card, PVC, PE , Foam ect

-

Speed:

-

58m/min

-

Cutting way:

-

Round Knife

-

Cutting precision:

-

0.1mm

-

Cutting Length:

-

0.1~9999.9mm

-

Automaticity:

-

PCL

-

Driving system:

-

Steping Motor

-

Package:

-

Wooden case

-

Advantage:

-

Working Stable

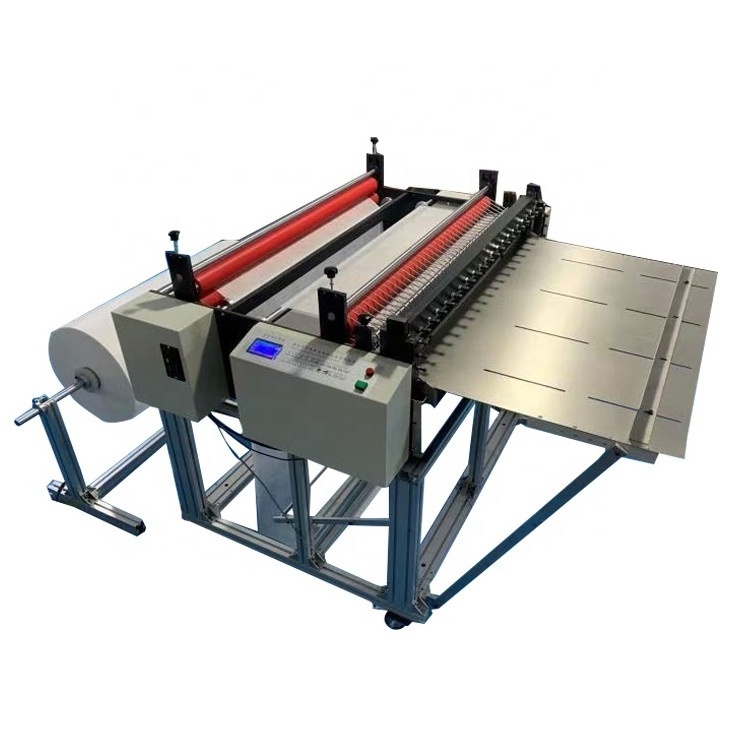

Automatic plastic film mask melt-blown fabric cutter machine+8618737189043

Table model

Vertical model

Introduction of the printing paper cutting machine

1. All kinds of film, cloth, paper and other roll materials can be cut.

2. The adjustable speed motor cooperates with the photoelectric sensor to realize automatic unwinding and synchronous cutting, with faster speed, higher efficiency and more accurate precision.

3. The machine adopts compact design, smaller volume, and is equipped with all-in-one foot cup casters, which can be moved and installed at any time.

4. Using a spring-type feeding mechanism with an adjustable angle receiving table, materials can be collected neatly regardless of thickness, saving labor.

5. Humanized design, simple operation, stable performance and easy maintenance. It can be cut regardless of the thickness of the material

Parameters of paper business card slitting machine

|

Voltage |

220V/50/60hz |

|

Cutting length |

0.1-9999.9mm |

|

Cutting speed |

58m/min |

|

Cutting Accuracy |

0.1mm |

|

Blade material |

sharp steel |

|

Cut width |

Customized (blade width 100/200/300/400/500/600mm or more big width |

Details of PVC PE FOAM slitting cutting machine

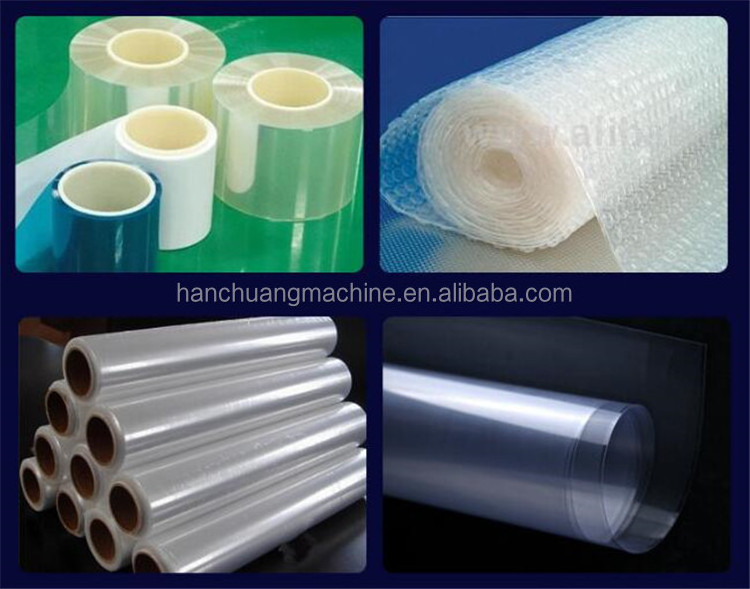

Application of slitting machine

Electronics industry, electrical industry, packaging industry, auto and motorcycle parts industry, motors, transformers, printing, clothing leather,

Luggage, outdoor products, toys and other industries

Scope of application:

Roll paper, insulating paper, release paper, kraft paper, barley paper, printing paper, label paper, textured paper, wallpaper,

Double-sided adhesive tape, PνC film, heat shrinkable film, PET film, protective film, OPP film, insulating film, release film, bubble film

Paper cutting machine pictures show

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.