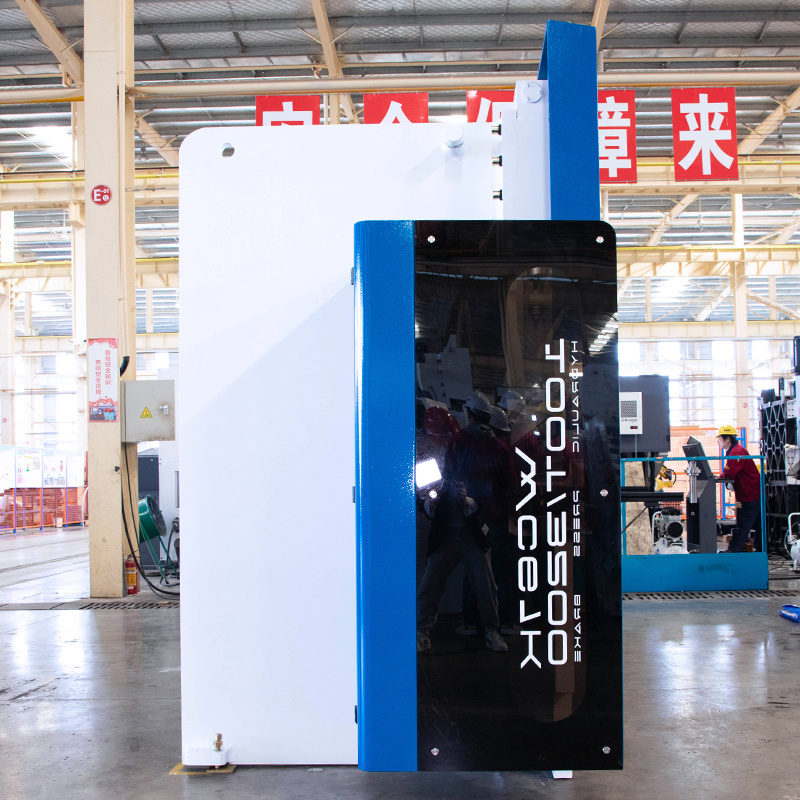

Made with state-of-the-art industrial design andtop-notch craftsmanship, with an aestheticappearance.

Heavy-duty machine frame, sturdy and durable,with integral welding structure and furnaceannealing treatment to maintain good machinetool accuracy.

Advanced production technology and strictquality control ensure the reliability of themachine tool.

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

250 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ADH

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product

-

Product name:

-

Metal steel metal plate bending CNC Hydraulic Press Brake

-

Bending Thickness:

-

4mm , 2 3 5 6 8 milimeter etc

-

Feature:

-

bending die, customized press brake tooling

-

Distance Between Column:

-

2510mm

-

Nominal Pressure:

-

110 Ton (optional: 40 50 70 110 135 170 220 250 ton etc

-

Table length:

-

1600 mm, 2500 3200mm 4000 5000 6000 mm 8000mm etc

-

Nominal Pressure (ton):

-

optional: 400 500 700 1100 1350 1700 2200 2500, etc

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tandem double type:

-

optional Tandem press brake

-

Press brake tooling:

-

standard bending mould 90 degree bending die

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

120 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

250 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ADH

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product

-

Product name:

-

Metal steel metal plate bending CNC Hydraulic Press Brake

-

Bending Thickness:

-

4mm , 2 3 5 6 8 milimeter etc

-

Feature:

-

bending die, customized press brake tooling

-

Distance Between Column:

-

2510mm

-

Nominal Pressure:

-

110 Ton (optional: 40 50 70 110 135 170 220 250 ton etc

-

Table length:

-

1600 mm, 2500 3200mm 4000 5000 6000 mm 8000mm etc

-

Nominal Pressure (ton):

-

optional: 400 500 700 1100 1350 1700 2200 2500, etc

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tandem double type:

-

optional Tandem press brake

-

Press brake tooling:

-

standard bending mould 90 degree bending die

Products Description

TORSION-SYNCHORONOUS PRESS BRAKE

Controller Brand: ESTUN E21, E300, E310P, DELEM DA41T, C ybelec CT8, etc

Capabilities: 30T - 600T

Controller Brand: ESTUN E21, E300, E310P, DELEM DA41T, C ybelec CT8, etc

Capabilities: 30T - 600T

Main component

Mechanical Structure

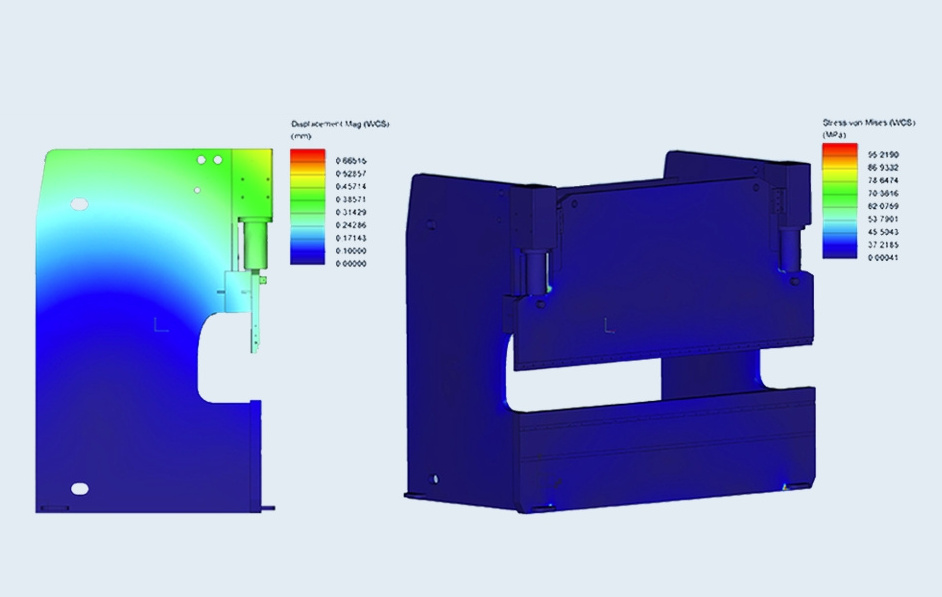

The press brake's structure mainly includes a frame, column, ram, worktable, main cylinder, and backgauge, all optimized through finite element analysis and 3D software, strong and rigid. Structural components are exquisitely designed, durable and stable, enhancing the machine's performance and lifespan.

Long Service Life Machine Body Frame

ADH press brake frames are supported by a 15-year warranty, indicating a strong commitment to long-term customer satisfaction and reliability.

The frame undergoes post-welding heat treatment to relieve stress, ensuring it remains deformation-free.

The frame undergoes post-welding heat treatment to relieve stress, ensuring it remains deformation-free.

· HD LCD display, Chinese and English language options

· X, Y-axis intelligent positioning

· Built-in dwell time, unloading delay design function, the operation is more simple, no time relays, reduce costs

· a key parameter backup and restore functionality

· Support multi-step programming

Motor

Siemens motors from Germany stand out due to their high efficiency and energy-saving features, directly contributing to reduced operational costs.

Designed with large starting torque and adherence to IEC standards, these motors ensure compatibility and ease of maintenance across various applications.

They offer excellent performance with low noise and vibration, alongside exceptional reliability, enhancing user experience and system longevity.

Constructed from high-strength cast iron, these gear pumps can withstand high pressure, ensuring durability and reliability in demanding conditions.

Designed with low sensitivity to oil pollution, which significantly extends the machine's service life by minimizing maintenance needs.

Rexroth hydraulic valves offer exceptional durability and high-pressure resistance, ensuring reliable performance under demanding conditions.

The machines equipped with these valves support multiple actions, such as rapid and slow descent, working speed bending, rapid return, and an emergency stop feature for enhanced operational flexibility and safety.

Features genuine Schneider parts from France, enhancing durability and stability for a prolonged service life.

Incorporates Estun's original adaptive electrical box assemblies, ensuring stable electrical operation with superior anti-interference capability.

The machine's rear stop assembly boasts a high-precision ball screw and adjustable stop finger, ensuring precise positioning for varied punches.

Manual lifting capabilities enhance the adaptability of the machine to accommodate a diverse range of punch types.

A servo motor's precision control enables exact positioning and movement, crucial for applications requiring fine adjustments and repeatability.

The Estun servo drive is engineered for precision, enhancing the accuracy of mechanical operations in industrial applications.

Optional configuration

Optional Controllers

Estun E310P

Cybelec CT8

DELEM DA41T

Optional DSP Laser Protection

The DSP laser safety device prevents hand injuries by protecting a zone just below the press brake's upper die.

Optional Light Curtain

It

enhances personal safety with features like strong anti-electromagnetic and anti-light interference capabilities, ensuring reliable operation in various environments.

Product Paramenters

|

Model

|

Bending Force

|

Bending Length

|

Daylight distance

|

Throat Depth

|

Ram Stroke

|

Open Height

|

Main Motor

|

Overall Dimensions

|

|

Unit

|

KN

|

mm

|

mm

|

mm

|

mm

|

mm

|

KW

|

L×W×H mm

|

|

WC67K/E-30t/1600

|

300

|

1600

|

1300

|

200

|

80

|

320

|

5.5

|

1650*1200*1700

|

|

WC67K/E-30t/2000

|

300

|

2000

|

1300

|

200

|

80

|

320

|

5.5

|

2000*1200*1700

|

|

WC67K/E-40t/2500

|

400

|

2500

|

2030

|

250

|

100

|

340

|

5.5

|

2500*1200*1900

|

|

WC67K/E-63t/2500

|

630

|

2500

|

2050

|

250

|

120

|

340

|

5.5

|

2500*1350*2100

|

|

WC67K/E-63t/3200

|

630

|

3200

|

2510

|

250

|

120

|

340

|

5.5

|

3200*1350*2100

|

|

WC67K/E-80t/2500

|

800

|

2500

|

2050

|

250

|

120

|

350

|

5.5

|

2500*1400*2150

|

|

WC67K/E-80t/3200

|

800

|

3200

|

2510

|

250

|

120

|

350

|

5.5

|

3200*1400*2150

|

|

WC67K/E-100t/2500

|

1000

|

2500

|

2050

|

320

|

120

|

380

|

7.5

|

2500*1500*2200

|

|

WC67K/E-100t/3200

|

1000

|

3200

|

2510

|

320

|

120

|

380

|

7.5

|

3200*1500*2300

|

|

WC67K/E-100t/4000

|

1000

|

4000

|

3100

|

320

|

120

|

380

|

7.5

|

4000*1500*2400

|

|

WX67Y-100t/4000

|

1000

|

4000

|

3100

|

420

|

160

|

435

|

7.5

|

4000*1650*2500

|

|

WC67K/E-125t/3200

|

1250

|

3200

|

2510

|

320

|

120

|

380

|

7.5

|

3200*1600*2350

|

|

WC67K/E-125t/4000

|

1250

|

4000

|

3100

|

320

|

120

|

380

|

7.5

|

4000*1600*2450

|

|

WX67Y-125t/4000

|

1250

|

4000

|

3100

|

420

|

160

|

435

|

7.5

|

4000*1700*2500

|

|

WC67K/E-160t/2500

|

1600

|

2500

|

2050

|

320

|

200

|

450

|

11

|

2500*1650*2700

|

|

WC67K/E-160t/3200

|

1600

|

3200

|

2510

|

320

|

200

|

450

|

11

|

3200*1650*2800

|

|

WC67K/E-160t/4000

|

1600

|

4000

|

3040

|

320

|

200

|

450

|

11

|

4000*1650*2800

|

|

WC67K/E-160t/5000

|

1600

|

5000

|

3800

|

320

|

200

|

450

|

11

|

5000*1750*3100

|

|

WC67K/E-160t/6000

|

1600

|

6000

|

4600

|

320

|

200

|

450

|

11

|

6000*1750*3300

|

|

WC67K/E-200T/3200

|

2000

|

3200

|

2600

|

320

|

250

|

540

|

15

|

3200*1900*3100

|

|

WC67K/E-200T/3200C

|

2000

|

3200

|

2510

|

320

|

200

|

450

|

11

|

3200*1650*2800

|

|

WC67K/E-200T/4000

|

2000

|

4000

|

3300

|

320

|

250

|

540

|

15

|

4000*1900*3100

|

|

WC67K/E-200T/4000C

|

2000

|

4000

|

3040

|

320

|

200

|

450

|

11

|

4000*1650*2800

|

Service

ADH service teams promise to provide professional, in-time, service all around the world!

Exhibition

Every year, ADH participate various exhibitons and fairs all around the world, such as Germany EMO fair,

Canton Fair,

in Italy, Germany, South America, South Korea, etc.

About us

EMPLOYEES: 617 SALES & SERVICES OFFICES: 67 R&D TECH: 43

Founded in March 2002, Anhui Donghai Machine Tool Co., Ltd. (Brand: ADH) is a comprehensive leading enterprise in the machine tool industry in China, which integrates automatic control system design, new product research and development, and equipment manufacturing innovation platform formation.

Our factory is located in Bowang District, Ma'anshan City, Anhui Province, only 30 kilometers away from Nanjing Lukou International Airport and can be reached within 30 minutes by car.

Manufacturing Technique

We have our own manufacturing equipments, including

T

empering furnace, 5-axis machining centers, Heavy-duty Shot Blasting Machines, CNC machining centers, grinding machines, drilling machines

, etc.

Certifications

Our Partners

Hot Searches